motorcycle frame rack

A technology for motorcycles and racks, applied in the direction of assembling vehicles, packaging food, packaging items, etc., can solve problems such as inability to test motorcycle frames, inability to keep warm, and scratches on the inner surface of pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Further detailed explanation through specific implementation mode below:

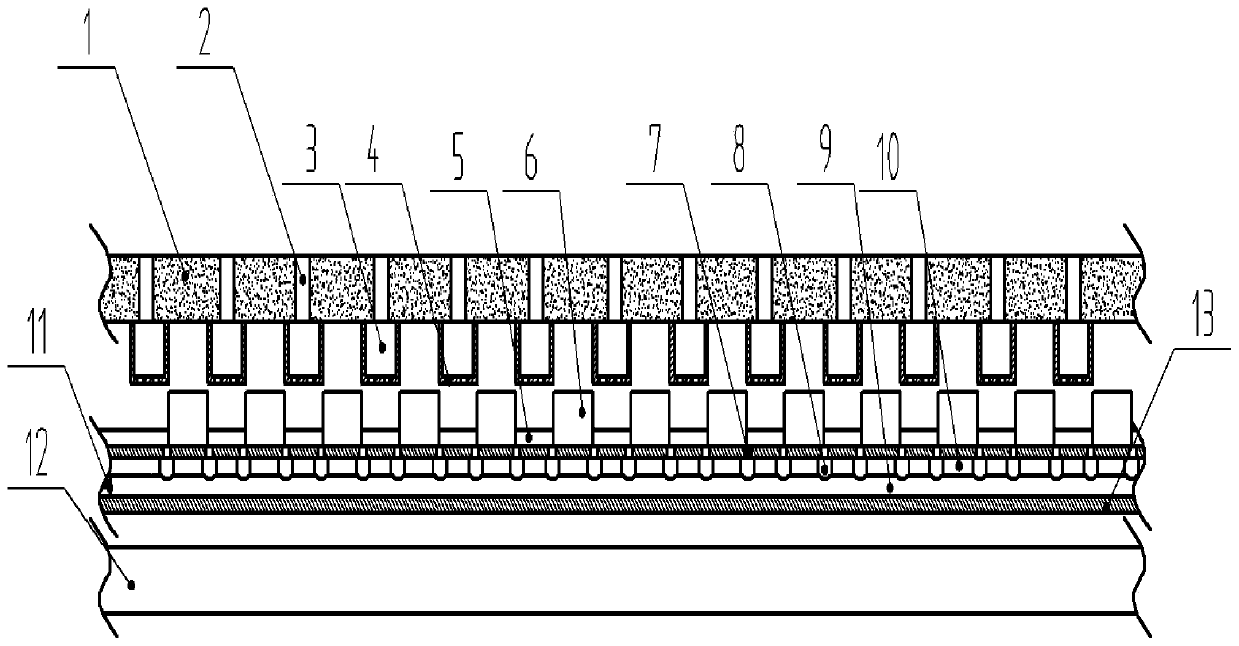

[0015] The reference signs in the drawings of the description include: heat transfer layer 1, water inlet hole 2, drainage block 3, through hole 4, water absorbent cotton 5, resistance heating element 6, air inlet hole 7, heat exchange tube 8, Venturi tube 9. Activity cavity 10, fan 11, photoelectric layer 12, high temperature resistant insulating medium layer 13.

[0016] The embodiment is basically as attached figure 1 Shown: motorcycle frame placement frame, including heating layer, high temperature resistant insulating medium layer 13 and photoelectric layer 12 arranged in sequence from top to bottom, heating layer includes heat transfer layer 1 and resistance heating element 6, photoelectric layer 12 includes solar energy Composed of photovoltaic panels and storage batteries, or the photoelectric layer 12 is powered by commercial power, and the high-temperature-resistant insulating medium l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com