Marking equipment of shifting forks

A printing label and equipment technology, applied in printing, printing machines, printing devices, etc., can solve the problems of invalid label processing, easy rubbing of marks, unfavorable fork processing and manufacturing, etc., to prevent blurred marks and scratches Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

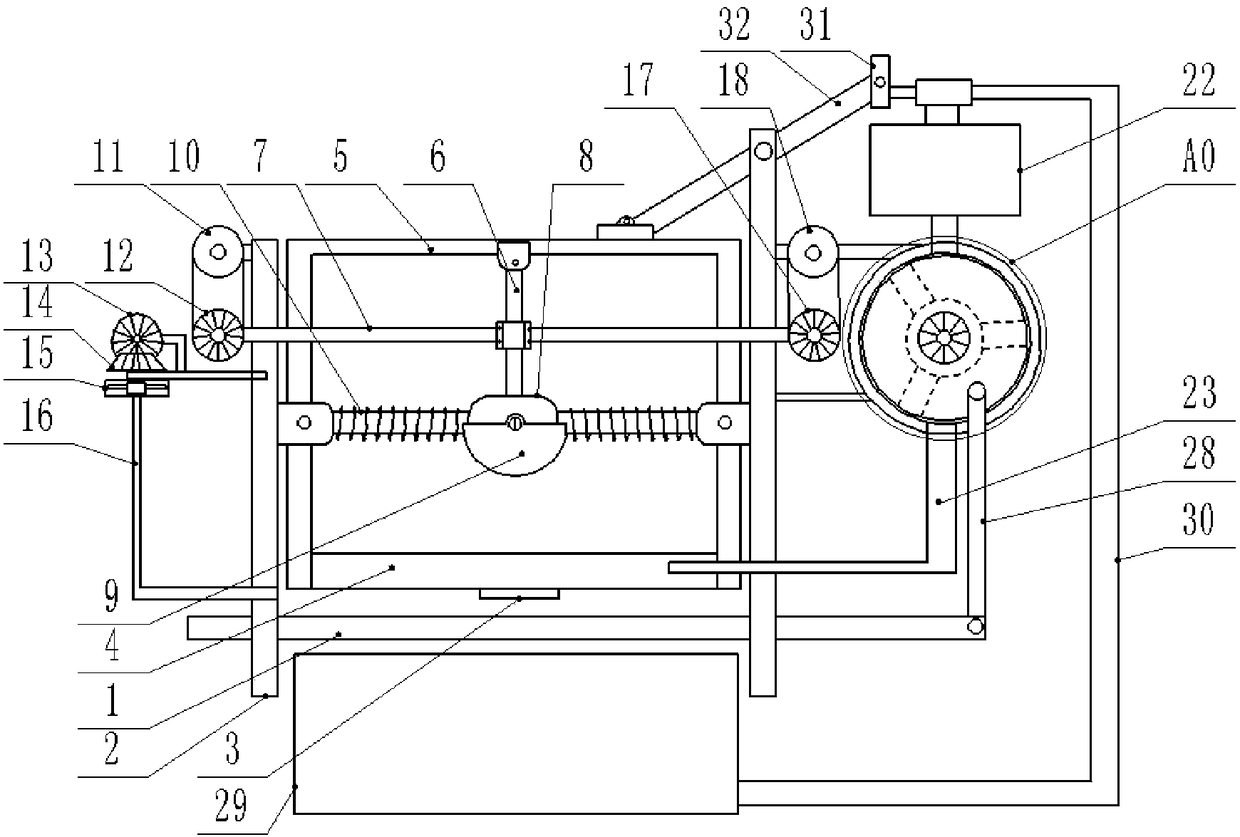

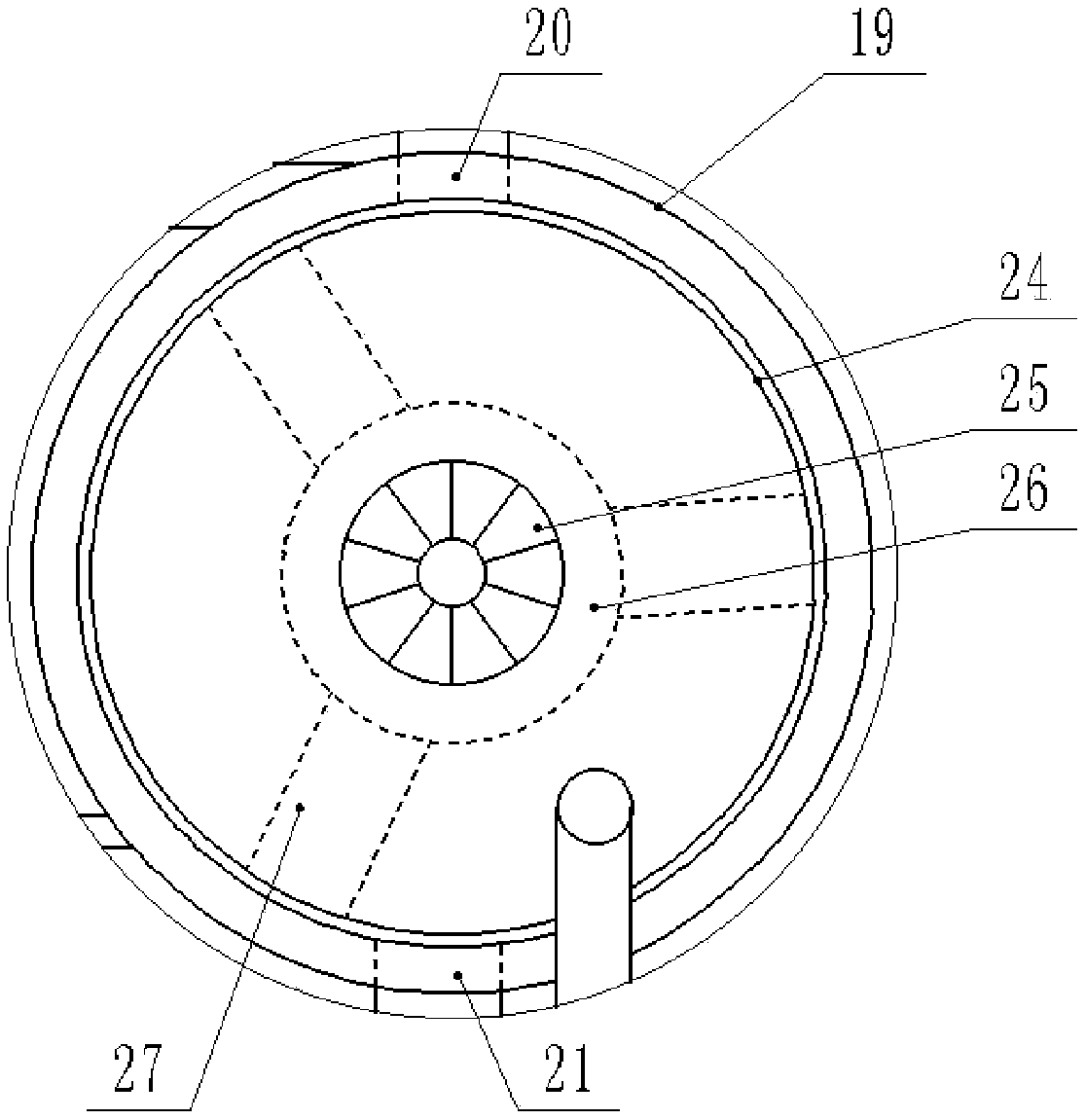

[0017] The reference signs in the accompanying drawings of the description include: platen 1, platform 2, printing head 3, paint touch-up box 4, bracket 5, swing bar 6, cross bar 7, motor 8, half-circle wheel 9, spring 10, the A round wheel 11, the first power bevel gear 12, the first main bevel gear 13, the first auxiliary bevel gear 14, fan 15, blowing pipe 16, the second power bevel gear 17, the second round wheel 18, circular groove 19, Material inlet 20, material outlet 21, paint box 22, paint inlet pipe 23, disk 24, second main bevel gear 25, cavity 26, channel 27, pull rod 28, paint storage tank 29, return pipe 30, valve 31. Leverage32.

[0018] Example figure 1 Shown: a fork marking equipment, including a marking table, the marking table includes a platen 1 and a stand 2, the left end of the platen 1 is hinged on the stand 2, and the stand 2 is vertically slidab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com