Cabin body inner wall robot automatic milling processing device

An automatic milling and processing device technology, applied in the direction of metal processing equipment, manipulators, milling machine equipment, etc., can solve the problems of cabin body processing in place, many measurement points, and processing efficiency constraints, so as to ensure accuracy, processing flexibility, and simple and compact structure , start the effect quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further elaborated below in conjunction with the accompanying drawings.

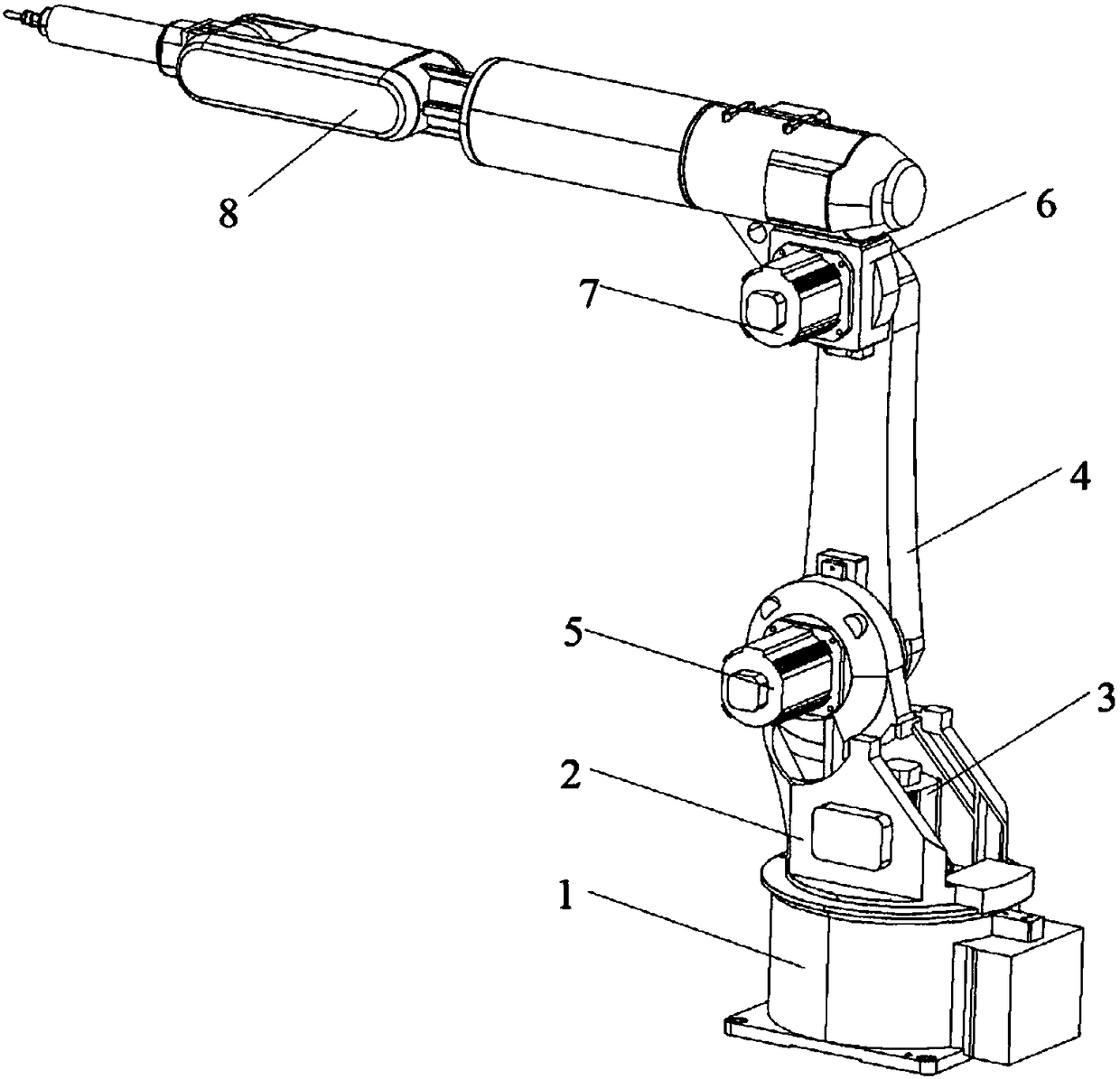

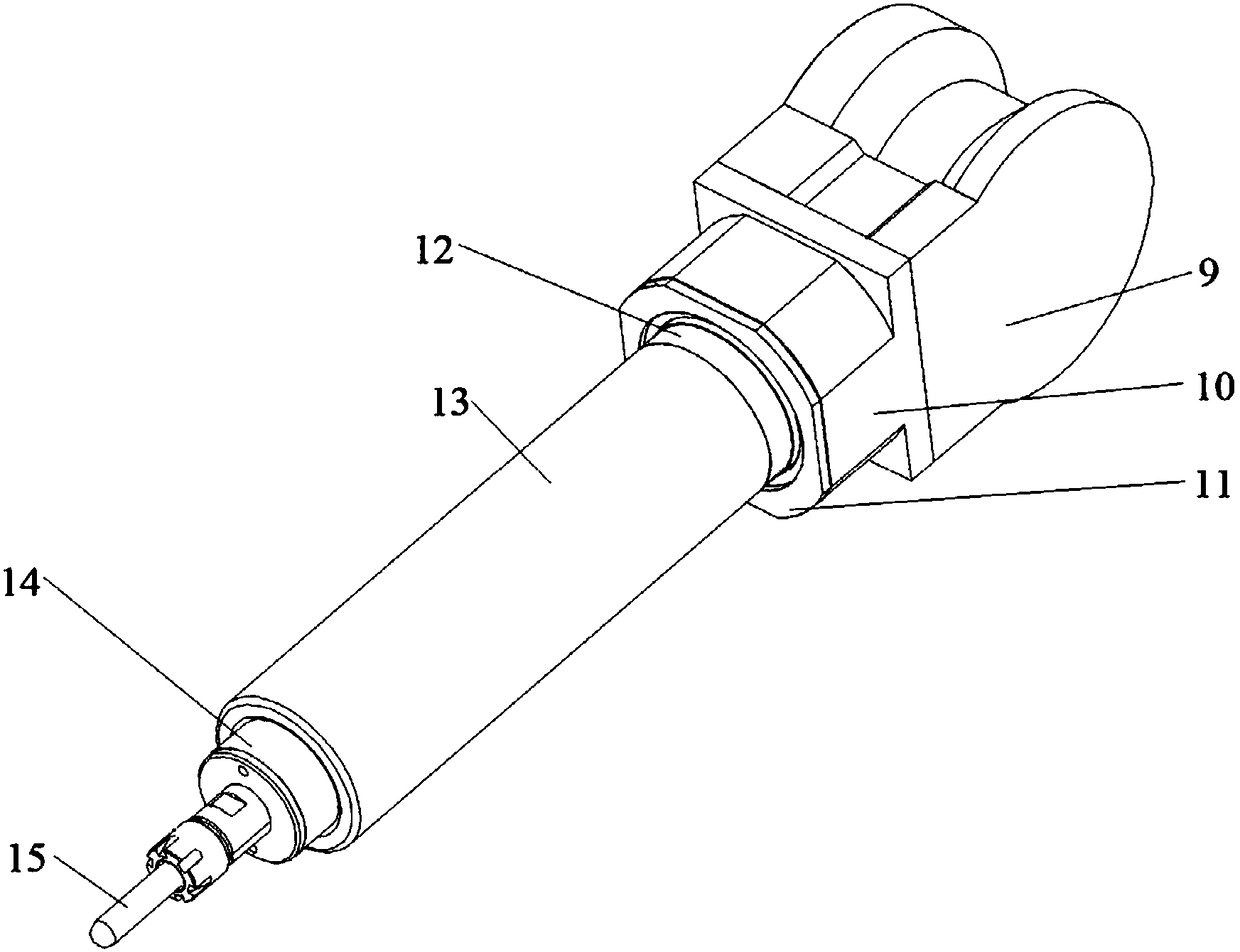

[0016] Such as Figure 1-2 As shown, a robot automatic milling device for a cabin inner wall of the present invention mainly includes a base 1, a turntable 2, a turntable motor 3, a boom 4, a boom motor 5, a box body 6, a forearm motor 7, and a forearm 8 , Wrist body 9, wrist body support 10, wrist body end cover 11, wrist body connecting flange 12, pneumatic main shaft 13, fixture 14, cutter 15. The turntable 1 and the turntable motor 3 are arranged on the base 1, and the turntable motor 3 drives the turntable 2 to rotate. The boom 4 and the boom motor 5 are arranged on the turntable 2, and the boom 4 is driven to rotate by the boom motor 5. The box body 6 and the small arm motor 7 are arranged on the boom 4, and the small arm 8 is arranged on the box body 6, and the small arm motor 7 drives the small arm 8 to rotate. The wrist body 9 is arranged between the forea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com