Double-spindle core moving type numerical control lathe

A technology of CNC lathes and double spindles, applied in the field of CNC lathes, can solve the problems of decreased production efficiency, slow material change rate, etc., and achieve the effects of improving precision, improving the degree of tightening, and increasing the degree of fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

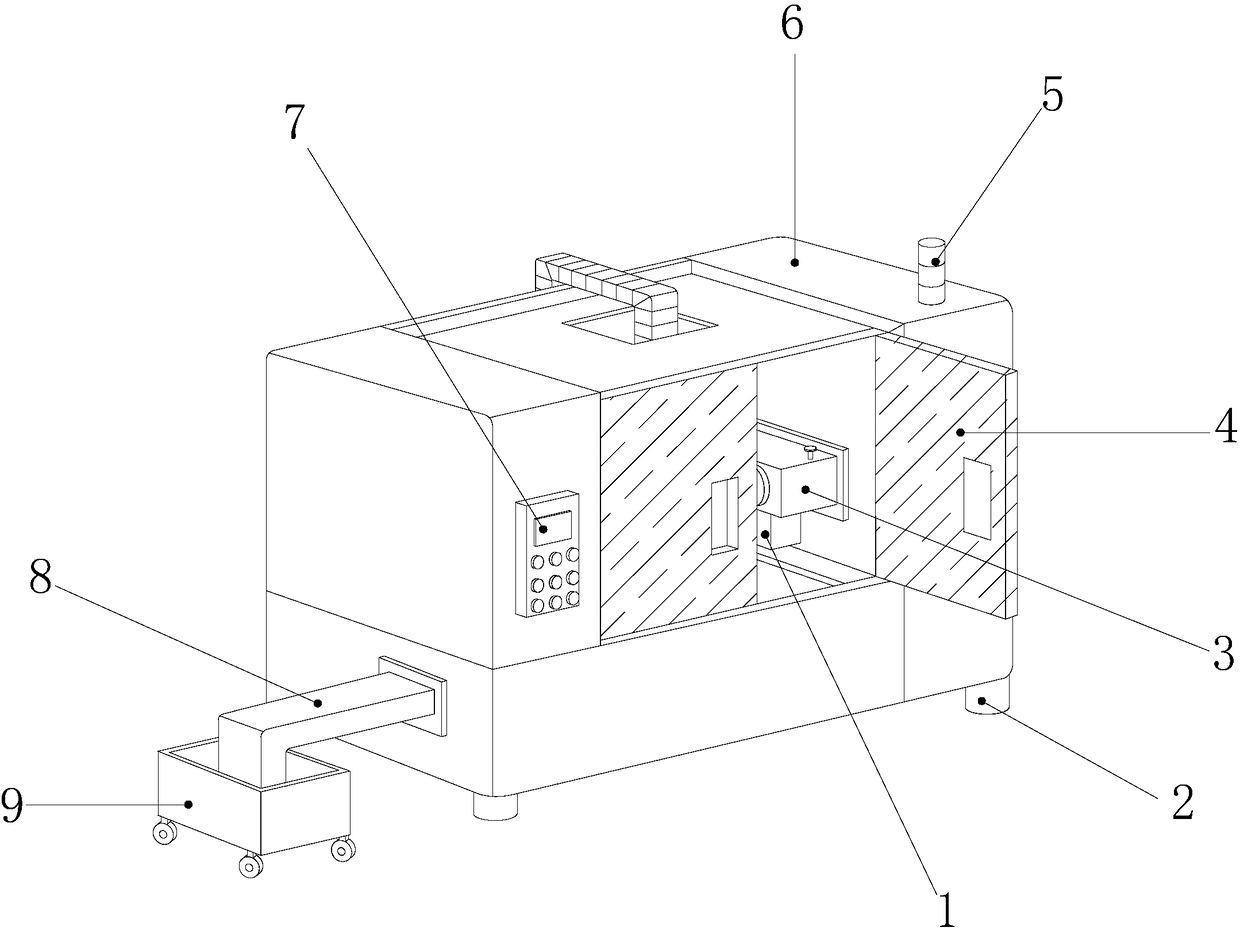

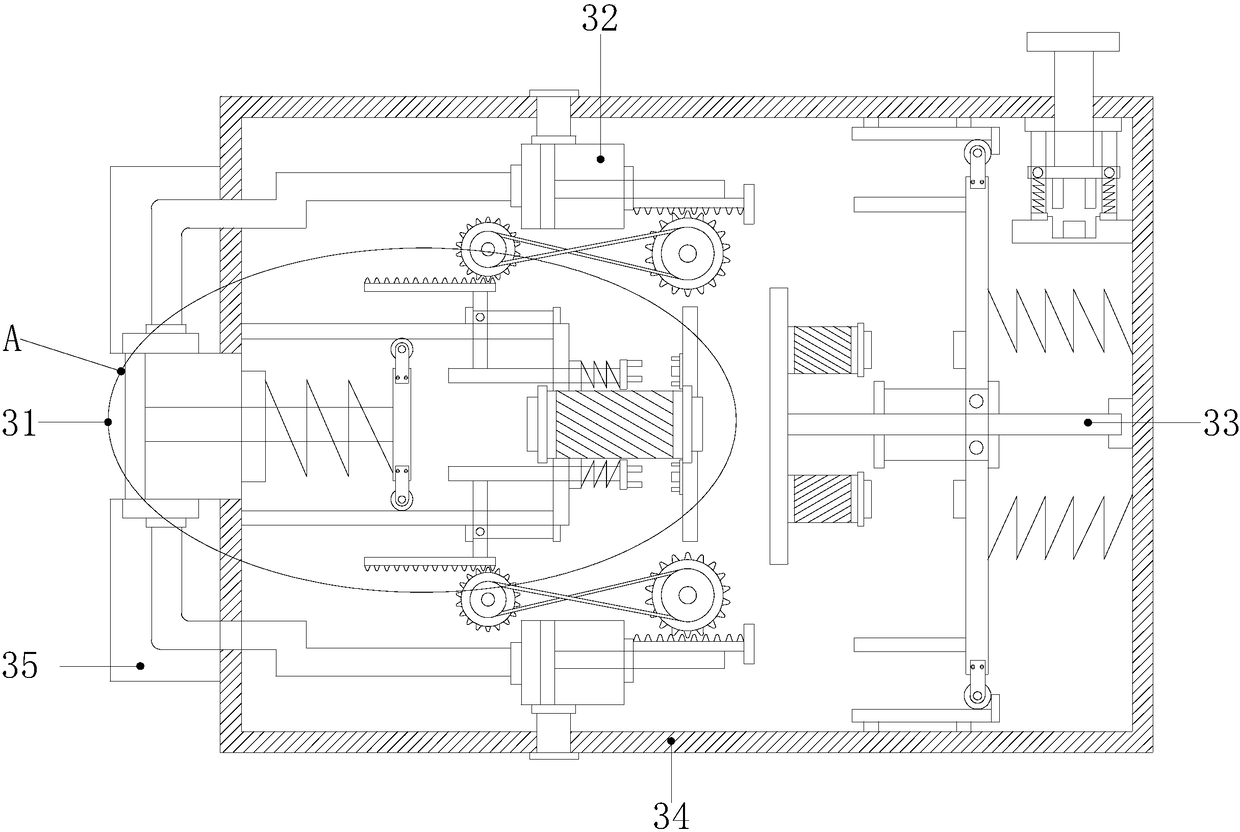

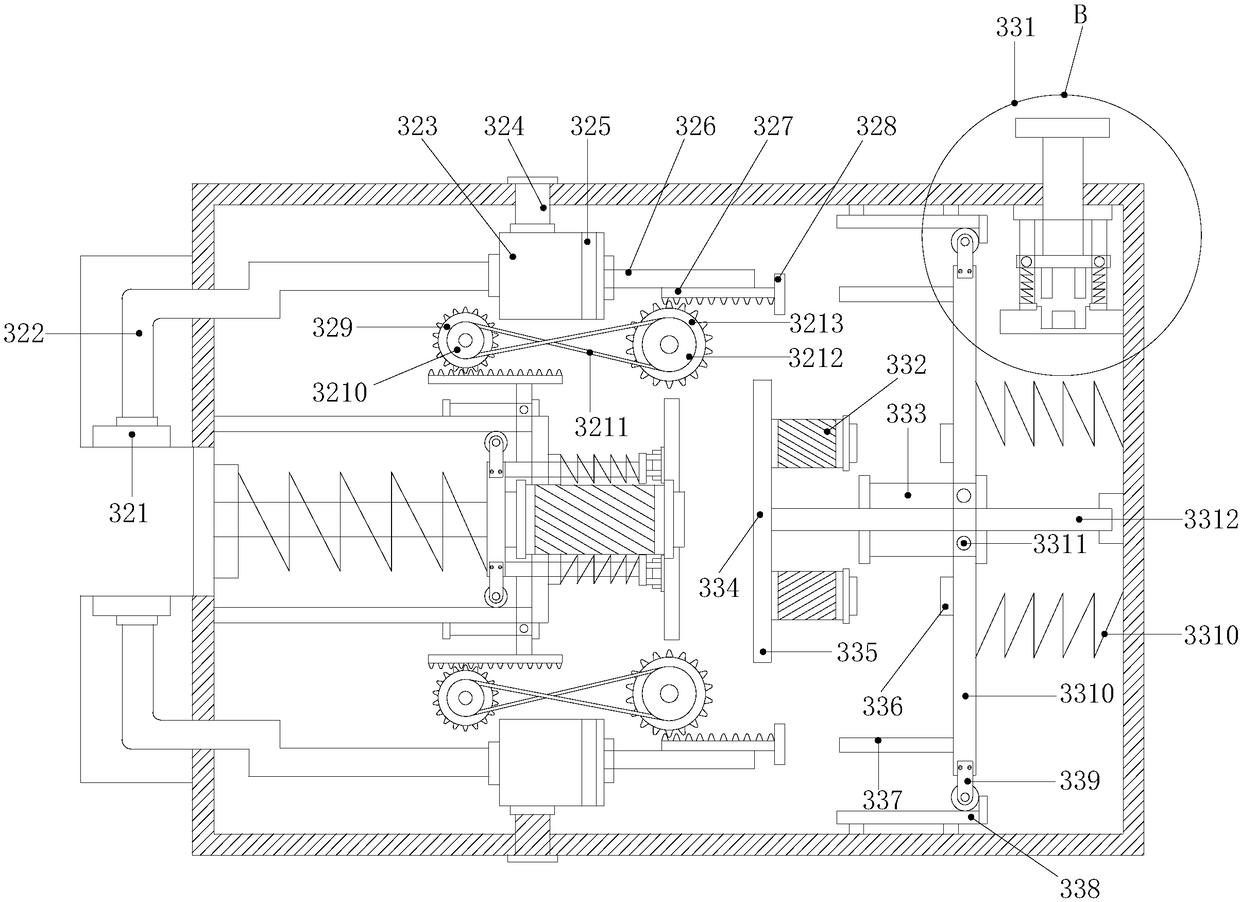

[0027] see Figure 1-Figure 7 , the present invention provides a dual-spindle core-moving CNC lathe, the structure of which includes a fixture with a rotating motor 1, a support leg 2, a workpiece adsorption and fixing device 3, a double-opening glass door 4, a three-color alarm light 5, a dual-spindle CNC lathe 6, and a controller 7. The chip conduit 8 and the mobile chip storage frame 9 are composed of four supporting feet 2 evenly spaced at the bottom of the double-spindle CNC lathe 6, and the supporting feet 2 are vertically fixed on the bottom of the double-spindle CNC lathe 6 , the left side of the double-spindle CNC lathe 6 is provided with a mobile chip storage frame 9, the double-spindle CNC lathe 6 is connected to the mobile chip storage frame 9 through a chip conduit 8, and the double-spindle CNC lathe The top of 6 is provided with a three-color alarm light 5, and the three-color alarm light 5 is vertically fixed on the double-spindle CNC lathe 6, and the front end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com