Gas supply system and gas supply method

A technology of gas supply system and gas supply device, which is applied in pipeline systems, chemical instruments and methods, gas/liquid distribution and storage, etc. It can solve problems such as inconvenient adjustment, insufficient intake air volume, and influence on intake stability, etc., to achieve Reduced environmental burden, easy installation, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

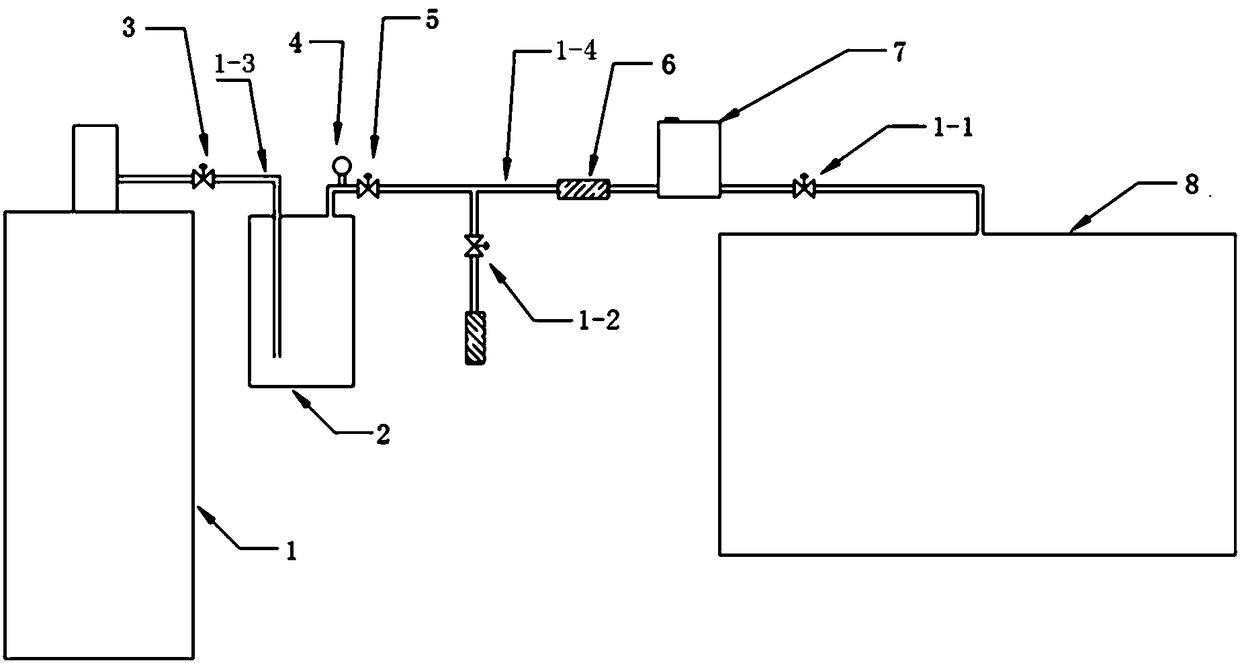

[0068] In this embodiment, the gas supply device adopts gas cylinders, such as figure 2 As shown, a digital display pressure gauge 4 is also installed on the pipeline E at the outlet of the gas cylinder, and the digital display pressure gauge is used for real-time monitoring of the pressure in the gas cylinder.

[0069] When this embodiment is used as a gas supply system for a shoe machine, anhydrous monomethylamine gas is stored in the gas cylinder, and the pressure control valve 3 is opened. After the gas in the gas cylinder enters the buffer tank 2, when the pressure in the buffer tank 2 reaches After a certain value (this value is much smaller than the pressure in the gas cylinder), the buffer tank 2 has completed gas storage, and the pressure control valve 3 is closed; The gas filter 6, the gas mass flow controller 7 and the flow outlet valve 1-1 enter the shoe machine cavity 8 to participate in the processing of shoe materials.

[0070] The continuous operation of the sh...

Embodiment 2

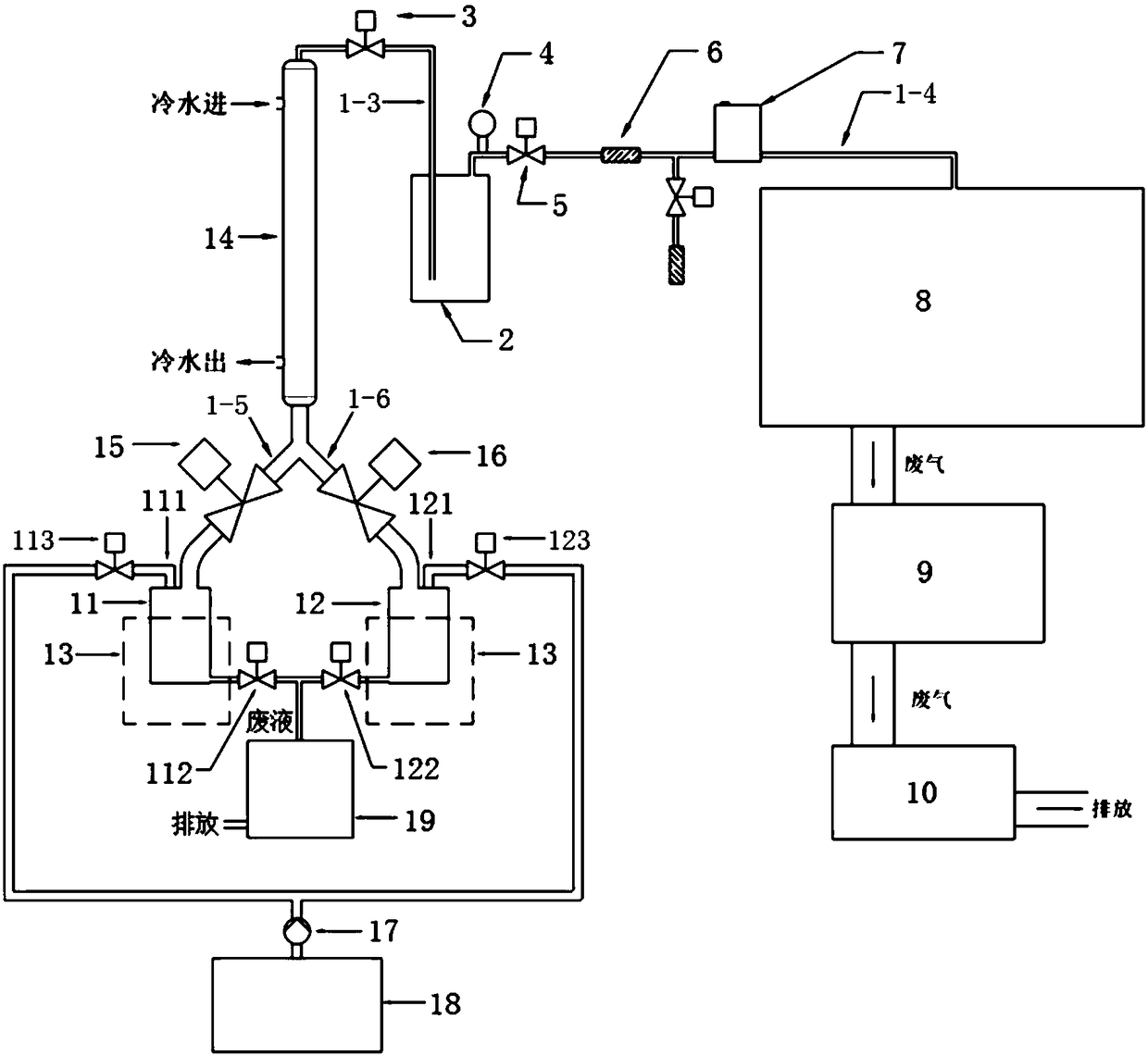

[0072] In this embodiment, the gas supply device adopts a solution heating device, such as image 3 As shown, the gas supply device 1 includes a raw material tank A11, a raw material tank B12, a heating device I12 and a condenser I14, and the bottoms of the raw material tank A and the raw material tank B are equipped with a heating device I, and the heating device I is preferably a thermal oil heating device ( Can be heated to 60-200 ℃) or water bath heating device (can be heated to 60-100 ℃), using heat transfer oil or water bath heating can effectively control the heating temperature and keep it in a safe range; condenser I passes through pipeline A1-5, pipeline B1 -6 is connected to raw material tank A and raw material tank B, and communicates with the inlet of buffer tank 2 through pipeline E. Gas outlet valve A15 and gas outlet valve B16 are respectively installed on pipeline A1-5 and pipeline B1-6. Raw material tank A and raw material The top of tank B is provided with f...

Embodiment 3

[0084] In this embodiment, the gas supply device adopts a reaction heating device, such as image 3 As shown, the gas supply device 1 includes a raw material tank C11', a raw material tank D12', a reaction tank 13', a condenser II14', and a heating device II15'. The raw material tank C and the raw material tank D pass through pipelines C1-7 and pipeline D1 respectively. -8 is connected to the reaction tank, the raw material valve 16' is installed on the pipeline C1-7, and the shut-off valve 17' is installed on the pipeline D1-8, and the reaction tank is connected with the entrance of the condenser II; the bottom of the raw material tank C and the raw material tank D are both There is a weighing module 18'; a heating device Ⅱ15' is installed at the bottom of the reaction tank, a pressure relief valve 131' is installed on the upper part, and a mixer 132' is installed inside, and the bottom of the reaction tank passes through the waste liquid outlet valve C133' and ultraviolet tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com