Combined connector

A connecting head and combined technology, which is applied in the direction of socket/socket connection, pipe/pipe joint/pipe fitting, passing element, etc., can solve the problems of high equipment investment cost, easy breakage, long construction period, etc., and save special equipment The effect of low investment cost, not easy to break, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

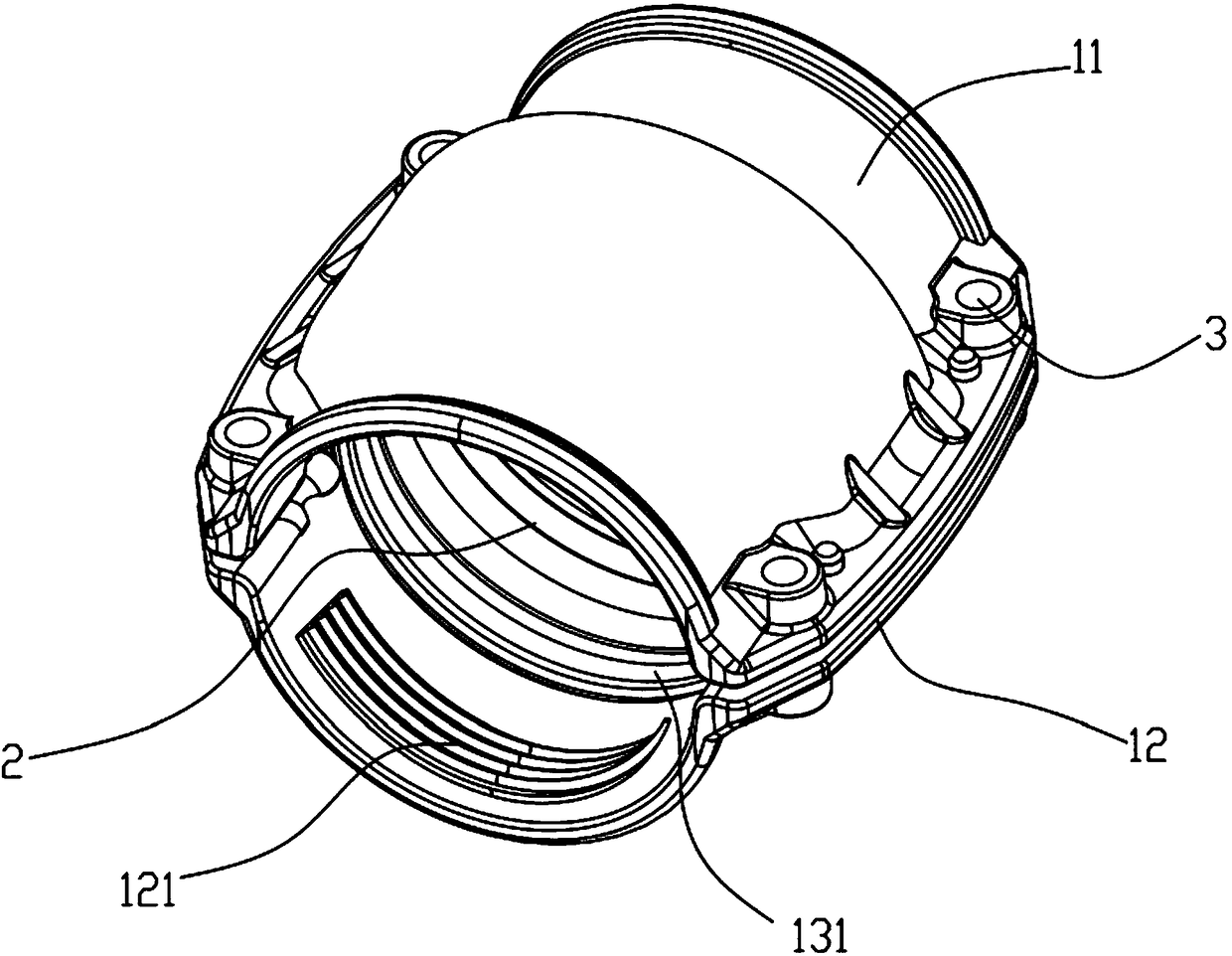

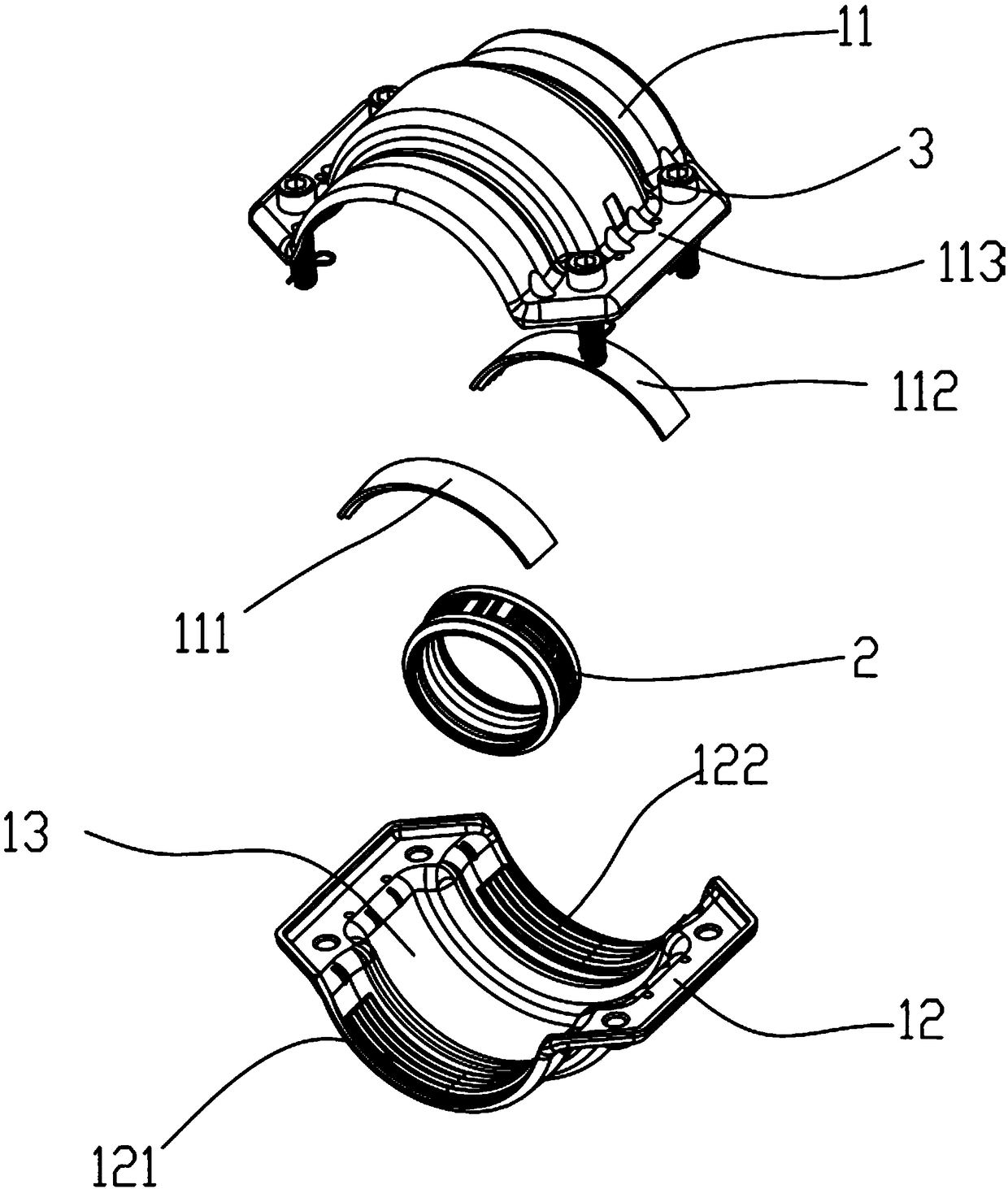

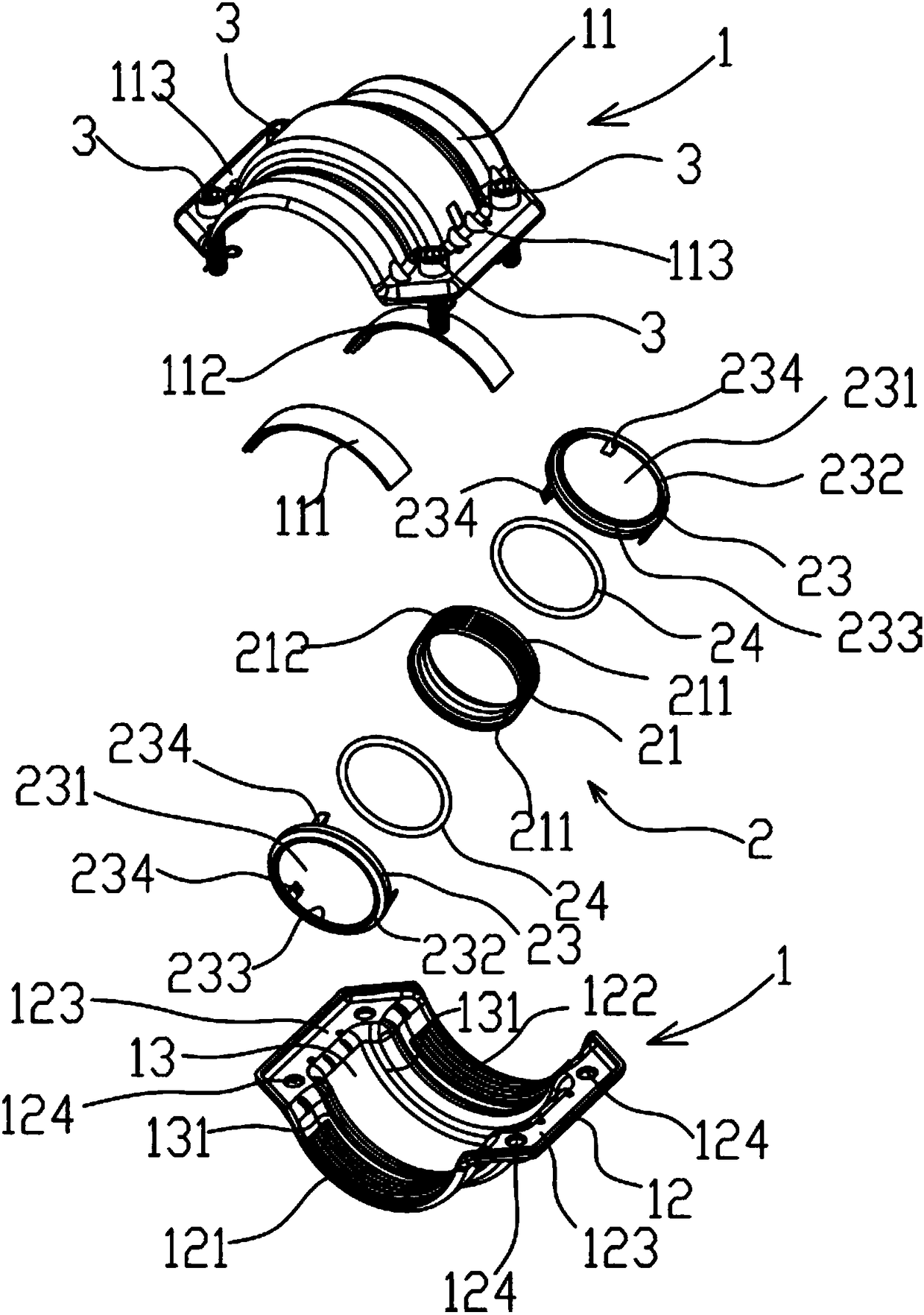

[0015] See attached Figure 1-3 , the present invention includes an outer casing 1 and a sealing device 2, the outer casing 1 is composed of a first semi-annular body 11 and a second semi-annular body 12, and the first semi-annular body 11 and the second semi-annular body 12 are connected by a fastener 3 , the inner cavity of the outer casing 1 is provided with an annular mounting groove 13, and the sealing device 2 is arranged in the annular mounting groove 13, and is characterized in that: on the inner wall of the first semi-annular body 11, it is installed by the annular The outer two ends of the groove 13 are respectively provided with a first arc-shaped sawtooth plate 111 and a second arc-shaped sawtooth plate 112. The third arc-shaped sawtooth plate 121 and the second arc-shaped sawtooth plate 122, the outer shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com