Method for determining optimal grouting timing of bolt grouting support in laboratory

A laboratory and grouting technology, applied in underground chambers, bolt installation, earthwork drilling, etc., can solve problems such as poor field operability and lack of theoretical basis for grouting timing, and achieve clear thinking, significant guiding significance, Actionable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

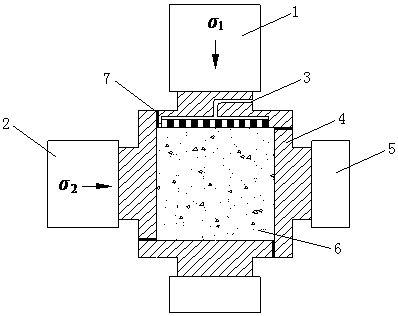

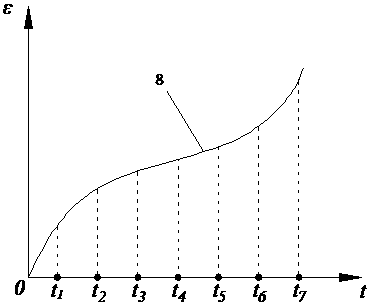

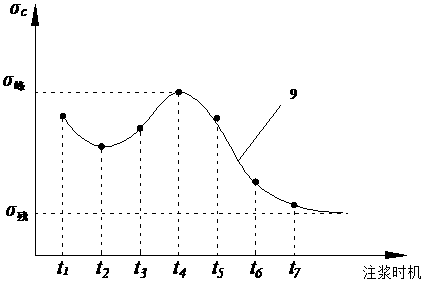

[0022] As shown in the figure, the method for determining the optimum grouting timing for anchoring and grouting support in the laboratory of the present invention includes the following steps:

[0023] Step 1): Collect the rock samples of the roadway surrounding rock in the coal mine, seal them with plastic wrap and transport them to the laboratory, cut the collected samples in the laboratory, and process them into cube rock samples with a size of 100mm×100mm×100mm6 (See figure 1 ); the cube rock sample 6 is placed in a cube container surrounded by six pressure plates 4, wherein a vertical pressure head 1 is arranged above the top pressure plate 4, and a horizontal pressure head 2 is arranged outside the pressure plate 4 on the left side; Reaction walls 5 are arranged on the outside of the bottom pressing plate 4, and sealing gaskets 7 are arranged at the joints of each pressing plate 4; and the top pressing plate 4 is provided with a slurry inlet 3, and a permeable plate is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com