Method for recycling metallic lithium from waste lithium ion batteries

A lithium-ion battery and metal lithium technology, applied in the field of selective recovery of valuable metal lithium, can solve the problems of poor selectivity of waste acid and waste alkali, complex element content testing, increased cost and difficulty, etc., to overcome difficult separation and good application Prospect, effect of reducing dissolution loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The positive electrode material in the waste lithium-ion battery that reclaims obtains and contains 2wt%H 2 o 2 The 2M sulfuric acid solution was mixed according to the solid-to-liquid ratio of 50g / L, stirred at 80°C for 3h, and filtered to obtain the leaching solution.

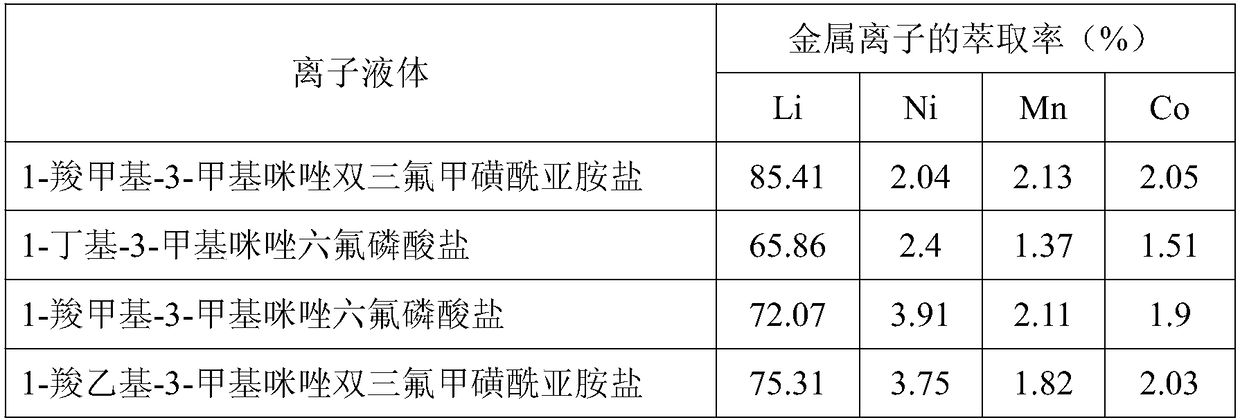

[0019] Table 1 The composition of leachate

[0020] Ion species

[0021] As a comparative example, take an appropriate amount of the above leachate to adjust the pH to 1, 2, 3 and 4 respectively, mix it with pure tributyl phosphate according to the ratio (O / A) = 1:1, stir at room temperature for 30 minutes, and then centrifuge at 6000rpm for 10 minutes. The separated organic phase was analyzed, and the extraction rates of metal lithium were calculated to be 2.43%, 2.38%, 2.51% and 2.49%, respectively.

Embodiment 2

[0023] The extraction system is composed of 1-carboxymethyl-3-methylimidazole bistrifluoromethanesulfonimide salt and tributyl phosphate at a volume ratio of 1:9.

[0024] Take an appropriate amount of the above leachate to adjust the pH to 3, mix it with the above extraction system according to the ratio (O / A)=1:1, stir at room temperature for 30 minutes, and then centrifuge at 6000rpm for 10 minutes. Analyzing the separated organic phase and raffinate, it is calculated that the extraction rate of metal lithium can reach more than 85%.

[0025] As a comparative example, the pH of the leaching solution was adjusted to 1, 2 and 4 respectively, and after extraction using the same method as above, the extraction rates of lithium metal were calculated to be 79.54%, 83.29% and 80.1%, respectively.

Embodiment 3

[0027] The extraction system is composed of 1-carboxyethyl-3-methylimidazole bistrifluoromethanesulfonimide salt and tributyl phosphate at a volume ratio of 1:9.

[0028] Adjust the pH value of the above leachate to 3, mix it with the above extraction system according to the ratio (O / A)=1:1, stir at room temperature for 30min, and then centrifuge at 6000rpm for 10min. Analyzing the separated organic phase and raffinate, it is calculated that the extraction rate of metal lithium can reach more than 85%.

[0029] As a comparative example, adjust the volume ratio of 1-carboxyethyl-3-methylimidazole bis-trifluoromethanesulfonimide salt to tributyl phosphate to be 1:4, 3:7 and 2:3 to form the extraction system, After extraction by the same method as above, the extraction rates of lithium metal were calculated to be 80.75%, 81.2% and 70.17%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com