Serratia marcescens strain and application thereof to production of ligninolytic enzyme and degradation of lignin

A technology of Serratia marcescens and lignin degrading enzyme, applied in the field of lignin degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

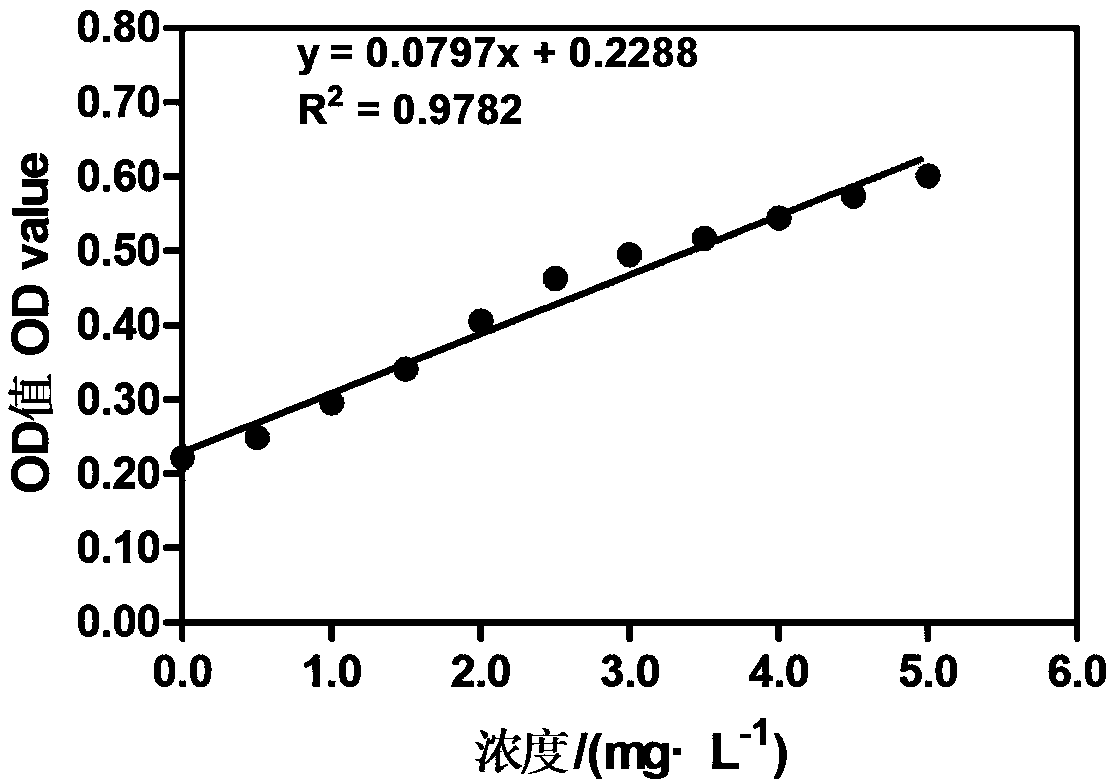

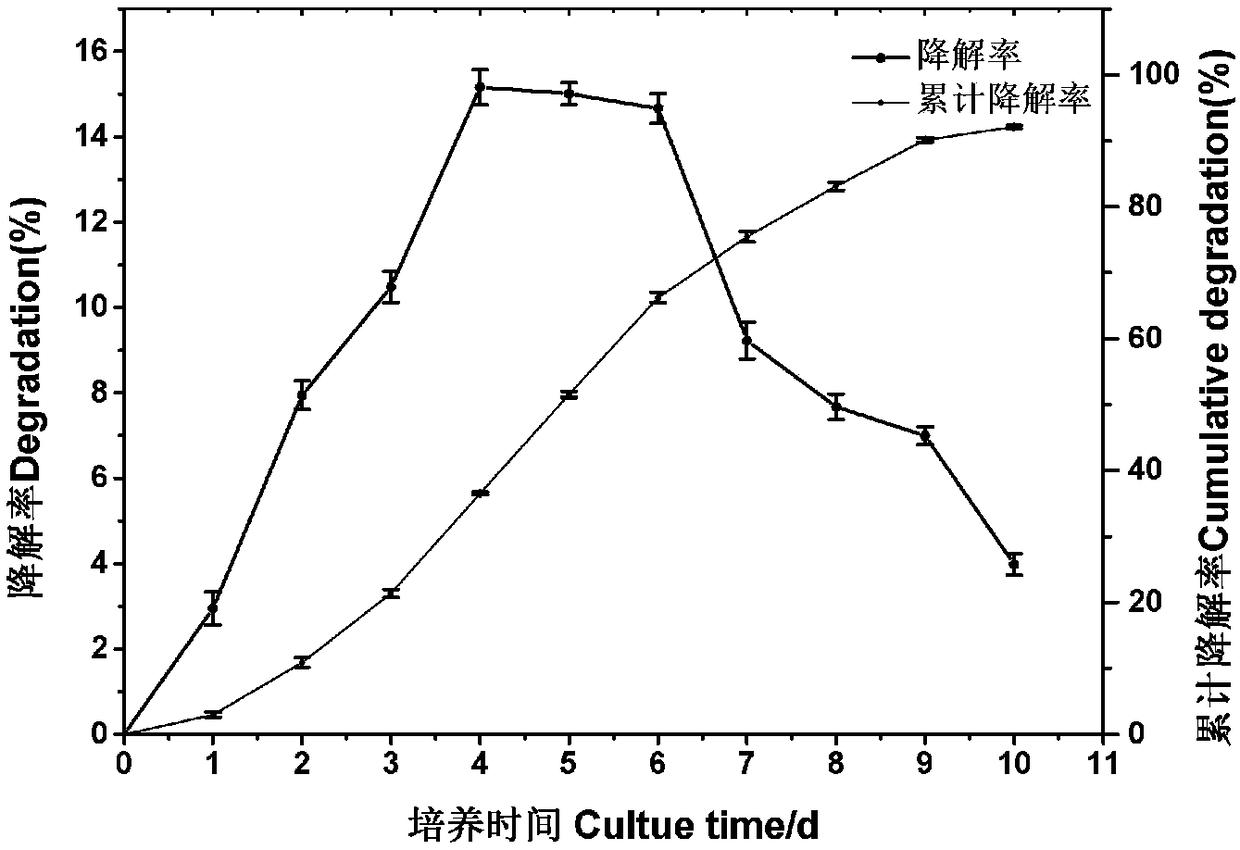

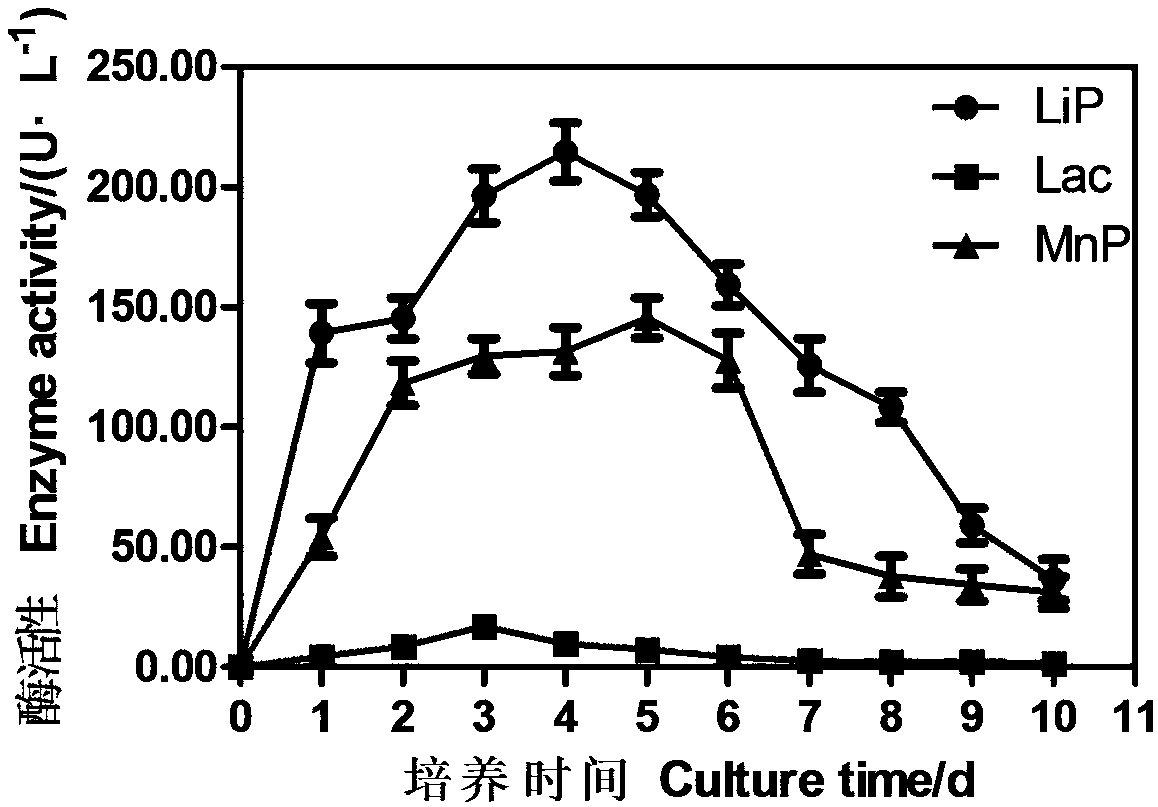

Embodiment 1

[0043] (1) Strain isolation and preservation

[0044] The tested strain of Serratia marcescens was isolated from the intestinal tract of Monochamus alternata larvae. The larvae of Monochamus alternata come from the masson pine forest (N26.150°; E119.593°) around Zhongbang Reservoir, Guantou Town, Lianjiang County, Fujian Province, and are collected by splitting the masson pine wood. The isolated Serratia marcescens strain is preserved in the China General Microorganism Culture Collection and Management Center, and the preservation number is CGMCCNO.15175.

[0045] (2) Expansion of bacterial strains

[0046] A single colony of the preserved Serratia marcescens was inoculated into a sterilized SOC medium, and placed in a 30° C. constant temperature incubator under dark conditions for activation culture to obtain an expanded culture of Serratia marcescens strains. SOC medium comprises the following content components: 2% (W / V) tryptone, 0.5% (W / V) yeast extract, 0.05% (W / V) NaC...

Embodiment 2

[0070] The Serratia marcescens bacterial strain SM01 preserved in Example 1 was obtained after expanded culture, and the bacterial liquid was inoculated into the liquid enzyme-producing medium with an inoculum size of 5%, and the liquid enzyme-producing medium was Kraft lignin 10.0g / L; (NH 4 ) 2 SO 4 2.0g / L; K 2 HPO 4 0.5g / L; KH 2 PO4 1.5g / L; MgSO 4 0.6g / L; CaCl 2 0.2g / L; FeSO 4 0.05g / L; MnSO 4 0.02g / L; Yeast extract is 2g / L; The concentration of described urea is preferably 5g / L. The pH of the medium is 6.5. Continuous culture was carried out at 30° C. for 4 days at a rotational speed of 200 rpm, and the lignin degradation rate was measured according to the method in Example 1. Centrifuge the cultured bacterial solution at 4°C for 5 minutes at a speed of 10,000 g, and take the supernatant, which is the crude enzyme solution. The obtained crude enzyme liquid was assayed for enzyme activity according to the method in Example 1. The results are shown in Table 2.

Embodiment 3

[0072] The Serratia marcescens strain SM01 isolated in Example 1 is obtained after expanded culture, and the bacterial liquid is inoculated into the liquid enzyme-producing medium with an inoculum size of 8%, and the liquid enzyme-producing medium is Kraft lignin 1.0g / L; (NH 4 ) 2 SO 4 2.0g / L; CaCl 2 0.5g / L; FeSO 4 0.2g / L; MnSO 4 0.06g / L; Yeast extract is 6g / L; The concentration of described urea is preferably 3g / L. The pH of the medium is 5.0. Continuous culture was carried out at 30° C. for 4 days at a rotational speed of 200 rpm, and the lignin degradation rate was measured according to the method in Example 1. Centrifuge the cultured bacterial solution at 4°C for 5 minutes at a speed of 10,000 g, and take the supernatant, which is the crude enzyme solution. The obtained crude enzyme liquid was assayed for enzyme activity according to the method in Example 1. The results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com