A kind of preparation method of intelligent energy-saving composite film

A composite film, intelligent technology, applied in the direction of radiation-absorbing coatings, coatings, polyester coatings, etc., can solve the problems of ultraviolet aging of tungsten bronze materials, shortening the phase transition response time, and high phase transition temperature, so as to shorten the phase transition response. time, excellent UV shielding performance, and the effect of improving weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Take 10g vanadium dioxide (VO 2 ) powder and 1g polyvinylpyrrolidone, join in the isopropanol solvent jointly, be mixed with the VO that mass fraction is 1% through high-speed stirring 2 slurry;

[0028] (2) Take 20gK 0.01 WO 3 Powder and 10g of polyvinylpyrrolidone are jointly added in the isopropanol solvent, and after high-speed stirring, the mass fraction is 15% K 0.01 WO 3 slurry;

[0029] (3) will VO 2 Slurry and K 0.01 WO 3 The slurry is mixed with a mass ratio of 50:1 and stirred at a high speed to obtain a composite slurry;

[0030] (4) mixing and stirring the polyurethane resin and the composite slurry at a mass ratio of 0.5:1 to obtain a polymer composite liquid;

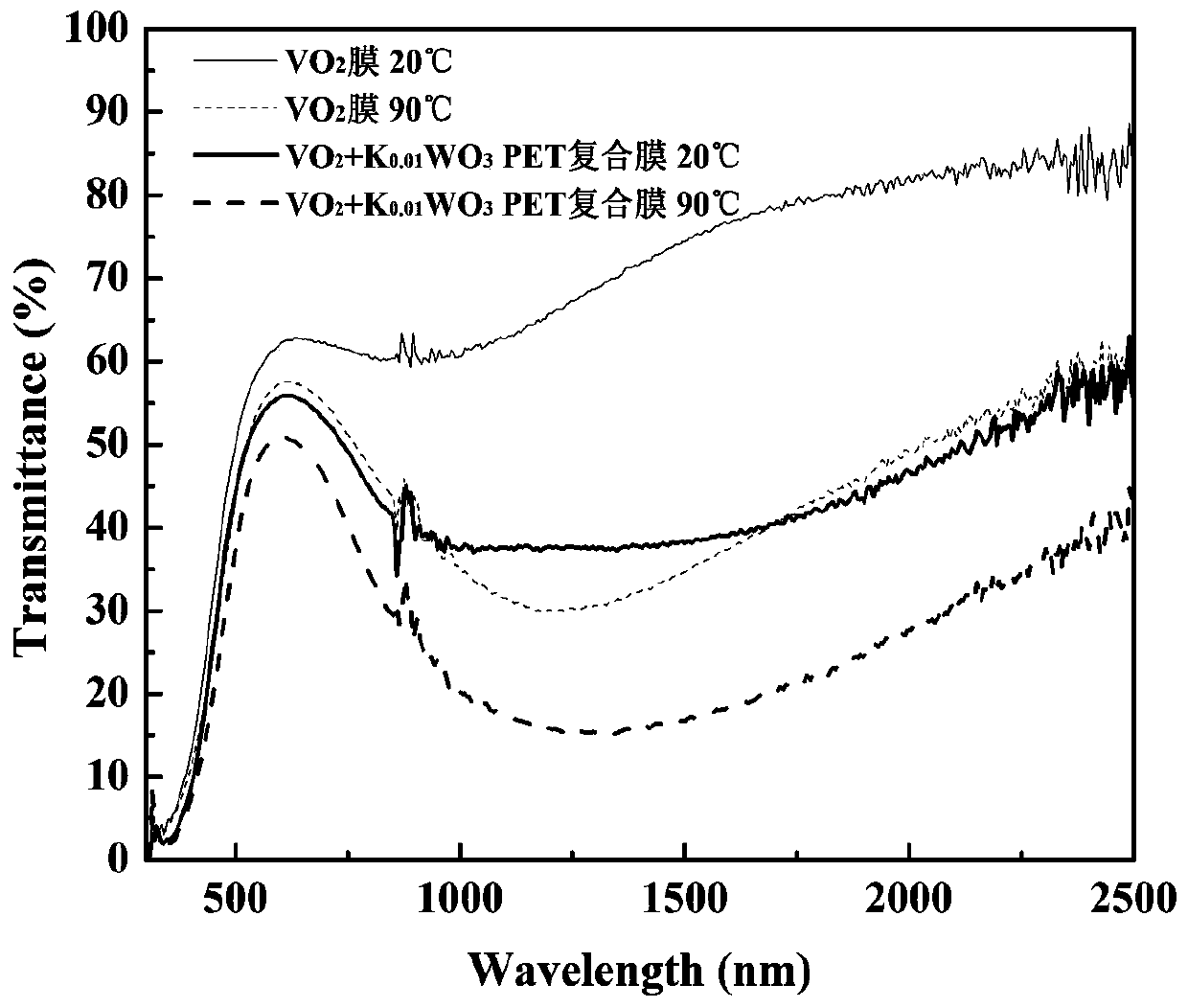

[0031] (5) Coating the polymer composite liquid on the PET base material by scraping to obtain a smart energy-saving PET composite film. The high and low temperature transmittance test chart of the obtained intelligent energy-saving PET composite film is as follows: figure 1 As shown...

Embodiment 2

[0034] (1) Take 15g of thermotropic liquid crystal and 10g of acrylate copolymer, join together in a certain amount of butyl acetate solvent, and mix it into a thermotropic liquid crystal slurry with a mass fraction of 30% through high-speed stirring;

[0035] (2) Take 10gCs 0.2 WO 3 Powder and 20g of polyvinylpyrrolidone are jointly added into a certain amount of ethanol solvent, and after high-speed stirring, it is prepared into Cs with a mass fraction of 10%. 0.2 WO3 slurry;

[0036] (3) The thermotropic liquid crystal paste and Cs 0.2 WO 3 The slurry is mixed with a mass ratio of 10:1 and stirred at a high speed to obtain a composite slurry;

[0037] (4) polyacrylic acid resin and composite slurry are mixed and stirred at a mass ratio of 6:1 to obtain a polymer composite liquid;

[0038] (5) The polymer composite liquid is coated on the glass substrate by spin coating, and an intelligent energy-saving glass composite film is obtained. The weather resistance of the pr...

Embodiment 3

[0040] (1) Take 5gAg 2 HgI 4 and 15g of sodium hexametaphosphate are jointly added to a certain amount of water, and are mixed with a mass fraction of 8% Ag through high-speed stirring. 2 HgI 4 slurry;

[0041] (2) Take 3gNa 0.4 WO 3 The powder and 3g of sodium hexametaphosphate were added to a certain amount of water, and after high-speed stirring, it was prepared into Na with a mass fraction of 2%. 0.4 WO 3 slurry;

[0042] (3) Ag 2 HgI 4 Slurry and Na 0.4 WO 3 The slurry is mixed with a mass ratio of 6:1 and stirred at a high speed to obtain a composite slurry;

[0043] (4) mixing and stirring the acrylic resin and the composite slurry at a mass ratio of 4:1 to obtain a polymer composite liquid;

[0044] (5) Coating the polymer composite liquid on the PVC base material by spraying to obtain an intelligent energy-saving PVC composite film. The weather resistance of the prepared composite film is greatly increased, and there is no change after 100 hours of weathe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com