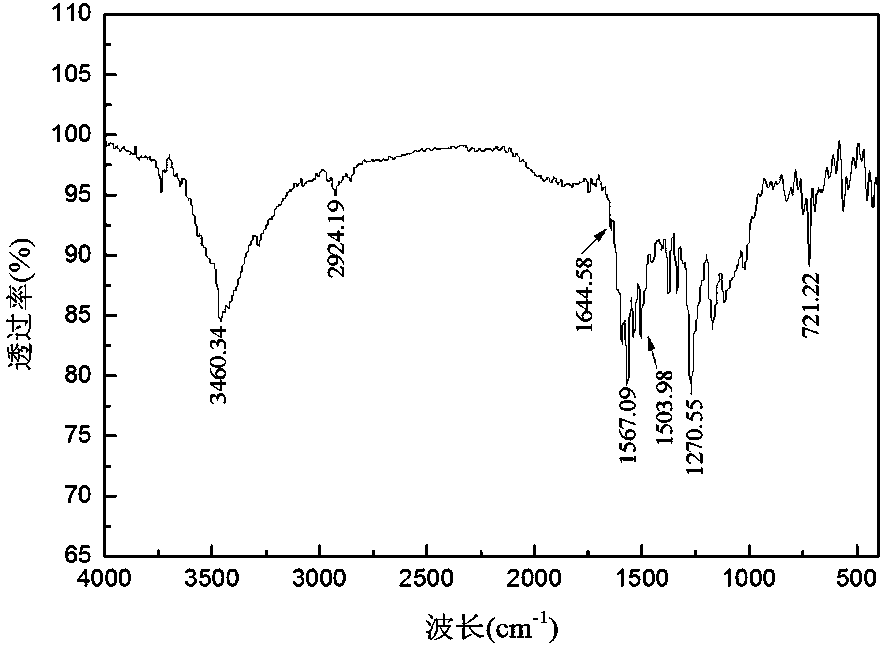

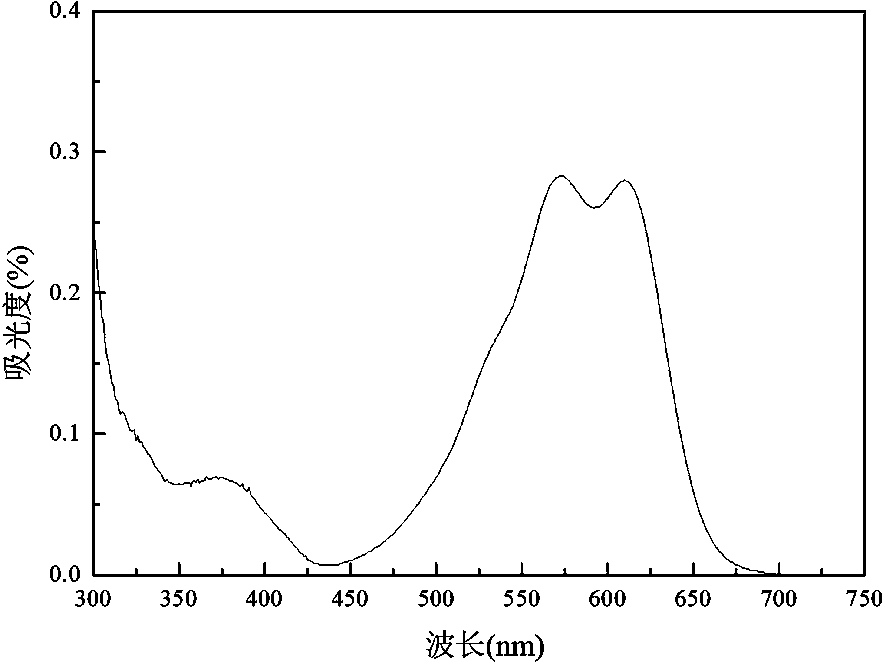

Blue anthraquinone active disperse dye and preparation method thereof

A technology of reactive disperse dyes and anthraquinones, applied in reactive dyes, dyeing methods, azo dyes, etc., can solve the problems of unsatisfactory natural fiber dyeing, good dyeing quality, and low manufacturing cost, and achieve good application prospects and high dyeing quality Good, low manufacturing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment takes the reaction with ethylenediamine as an example to prepare the precursor of the blue anthraquinone reactive disperse dye, and its reaction formula is:

[0023] .

[0024] The specific steps are:

[0025] Take 0.24g of 1,4-dihydroxyanthraquinone and its leuco 1,4-diaminoanthraquinone 0.619g and 0.462ml of isobutanol in a three-necked flask, and dissolve 6.840mL of aniline and 1ml of ethylenediamine in In 15ml of 20% isobutanol solution, keep stirring at 60°C for 2 hours under nitrogen protection; heat for 2 hours and then raise the temperature to 108°C and boil at this temperature for 3 hours; cool down to 95°C and add copper acetate and piperidine catalysts, 1,4 - The molar ratio of dihydroxyanthraquinone to copper acetate is 1:1.5, and an appropriate amount of piperidine is heated to 108°C for boiling for 3 hours; charged with oxygen for 3 hours; cooled to room temperature, and the reaction is complete. Using petroleum ether and dichlorometha...

Embodiment 2

[0037] The precursor provided in Example 1 of the present invention is used to prepare anthraquinone reactive disperse dyes with α-bromoacrylamide as the active group, and the reaction formula is:

[0038] .

[0039] Specific steps are as follows:

[0040] Take 1 mmol (0.357 g) of the dye precursor provided in Example 1 and dissolve it in 15 mL of dichloromethane, and control the temperature within the range of 0-5 °C. Take 0.0015mol of 2,3-dibromopropionyl chloride, dilute it in 5mL of dichloromethane, and slowly add it dropwise, raise the temperature to 35°C, stir for 1h, add 1mL of triethylamine, and stir for 3h. After the reaction, add water (about 350 mL) to dilute, precipitate flocculent precipitate, filter with suction, wash with water, and dry in vacuum to obtain a blue solid. Then use petroleum ether and dichloromethane (1:2, v / v) as the eluent for chromatographic column separation and purification to obtain a blue solid, which is anthraquinone reactive disperse d...

Embodiment 3

[0045] In this example, 1,4-butylene diamine is used as a reactant to prepare a blue anthraquinone reactive disperse dye precursor. The specific steps are as follows:

[0046] Take 0.24g of 1,4-dihydroxyanthraquinone and its leuco 1,4-diaminoanthraquinone 0.619g and 0.462ml of isobutanol in a three-necked flask, and simultaneously put 6.840mL of aniline and 1.5ml of 1,4- Dissolve butanediamine in 15ml of 20% isobutanol solution, heat and stir at 60°C for 2 hours under nitrogen protection; heat for 2 hours and then raise the temperature to 108°C and boil at this temperature for 3 hours; cool down to 95°C and add copper acetate and piperidine Catalyst, the molar ratio of 1,4-dihydroxyanthraquinone to copper acetate is 1:3, appropriate amount of piperidine, the temperature is raised to 108°C and boiled for 3 hours; filled with oxygen for 3 hours; cooled to room temperature, the reaction is completed. Using petroleum ether and dichloromethane (1:3, v / v) as the eluent for chromatog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com