Novel sedimentation pool for sewage plant

A technology for sewage plants and sedimentation tanks, applied in sedimentation treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of low work efficiency, too many components, high cost, etc., to reduce pollution The effect of reducing the amount of mud deposition, reducing manufacturing costs, and extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

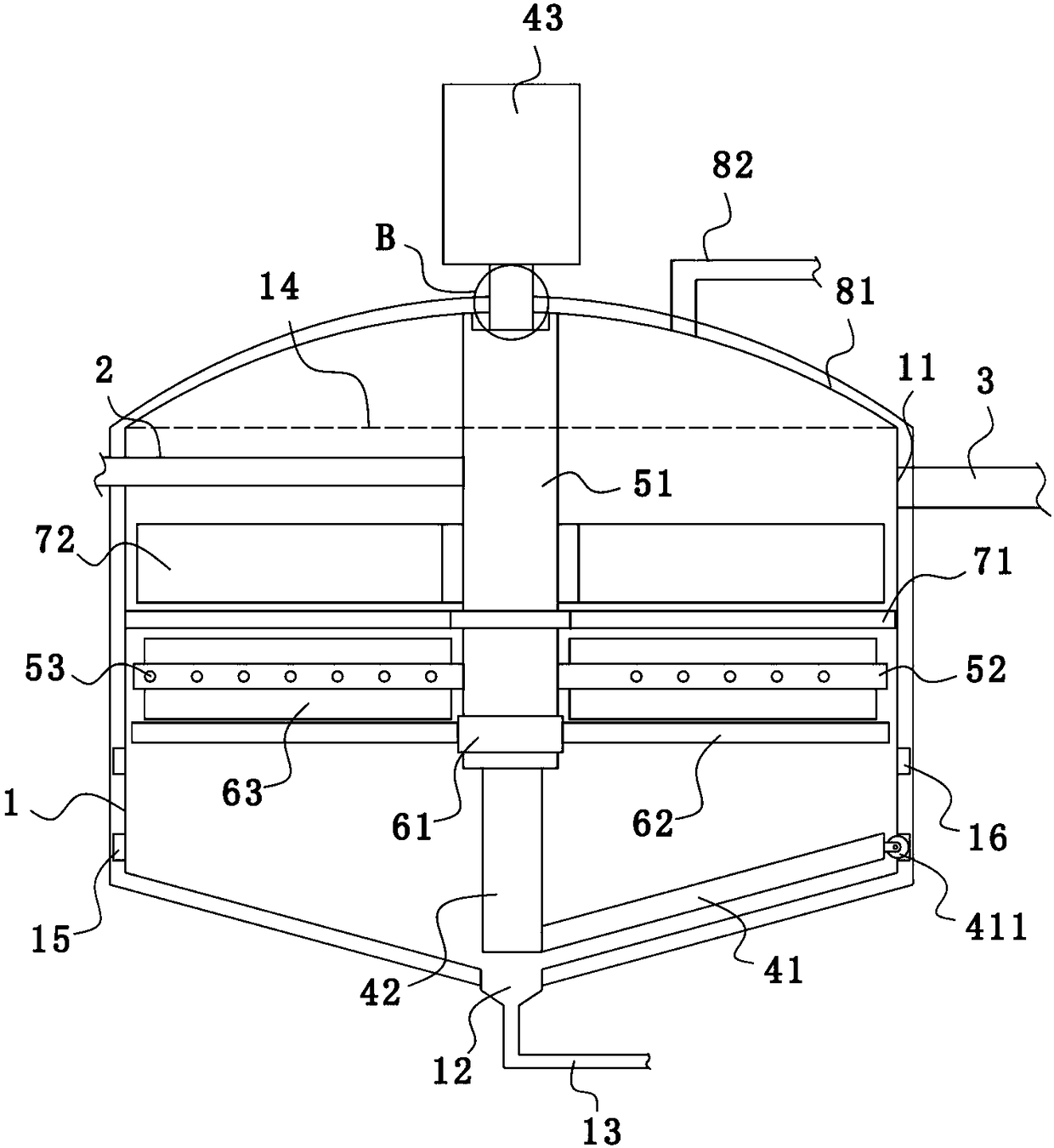

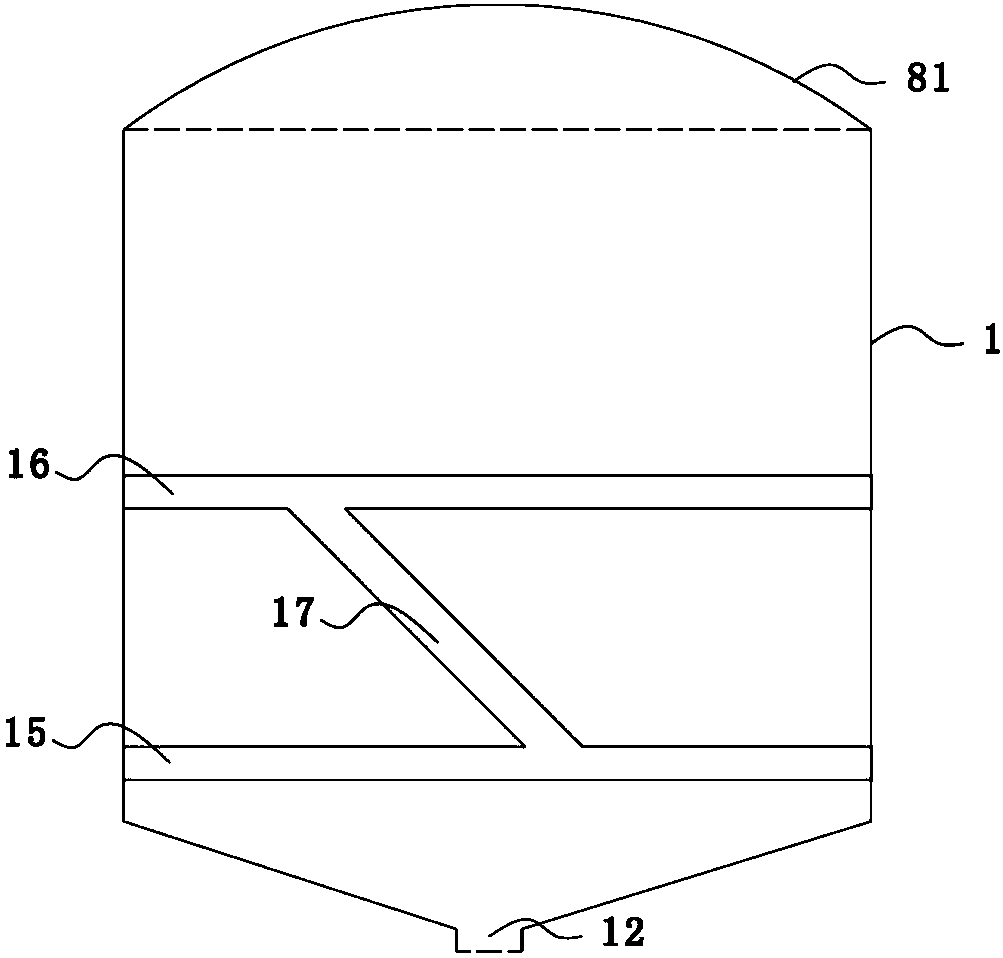

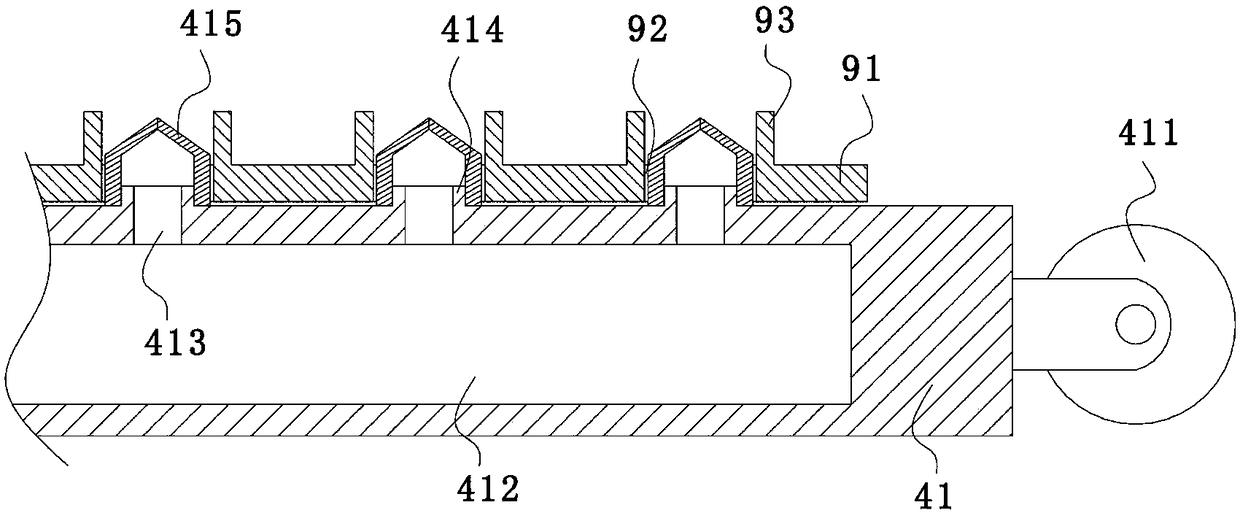

[0020] Such as Figure 1-5 As shown, a new type of sedimentation tank used in a sewage plant includes a tank body 1, a water inlet pipe 2, a water distribution unit located in the tank body, a biological filler unit, a mud scraping device, a gas recovery device and an outlet pipe 3; specifically , the mud scraping device includes a mud scraper rod 41, a drive rod 42, a first drive member 43 and a second drive member, the mud scraper rod 41 is arranged on the bottom surface of the pool body 1, and the drive rod 42 is arranged on The central position of the pool body, the lower end is fixedly connected with the mud scraper rod 41, and the upper end passes through the pool body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com