Diamond wire cutting machine

A technology of cutting machine and diamond wire, which is applied in the direction of working accessories, fine working devices, stone processing equipment, etc., can solve the problems of inconsistent cutting line speed, increase equipment manufacturing cost, high power of servo motor, etc., and achieve stable line speed The effect of constant, saving manufacturing cost, and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

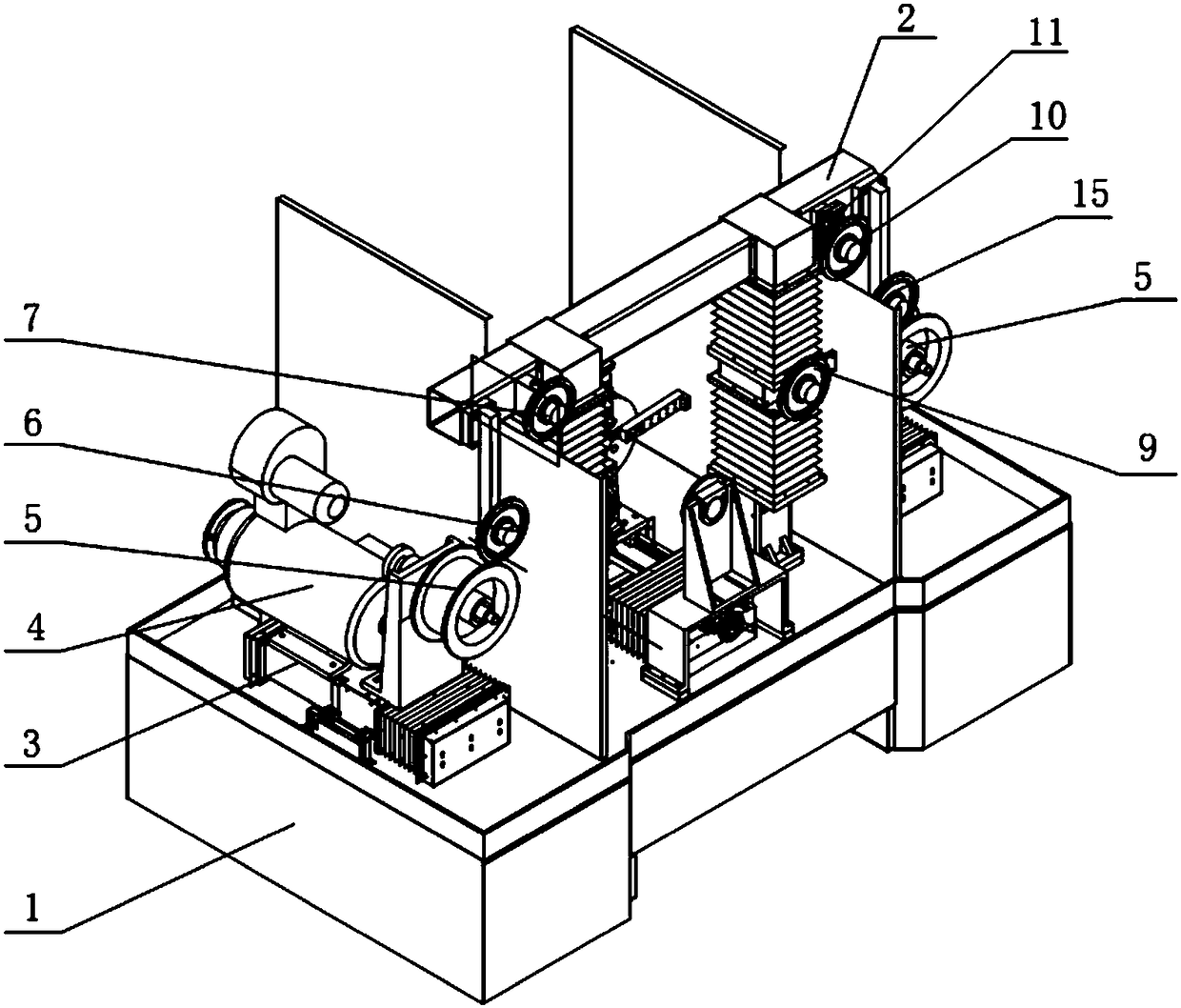

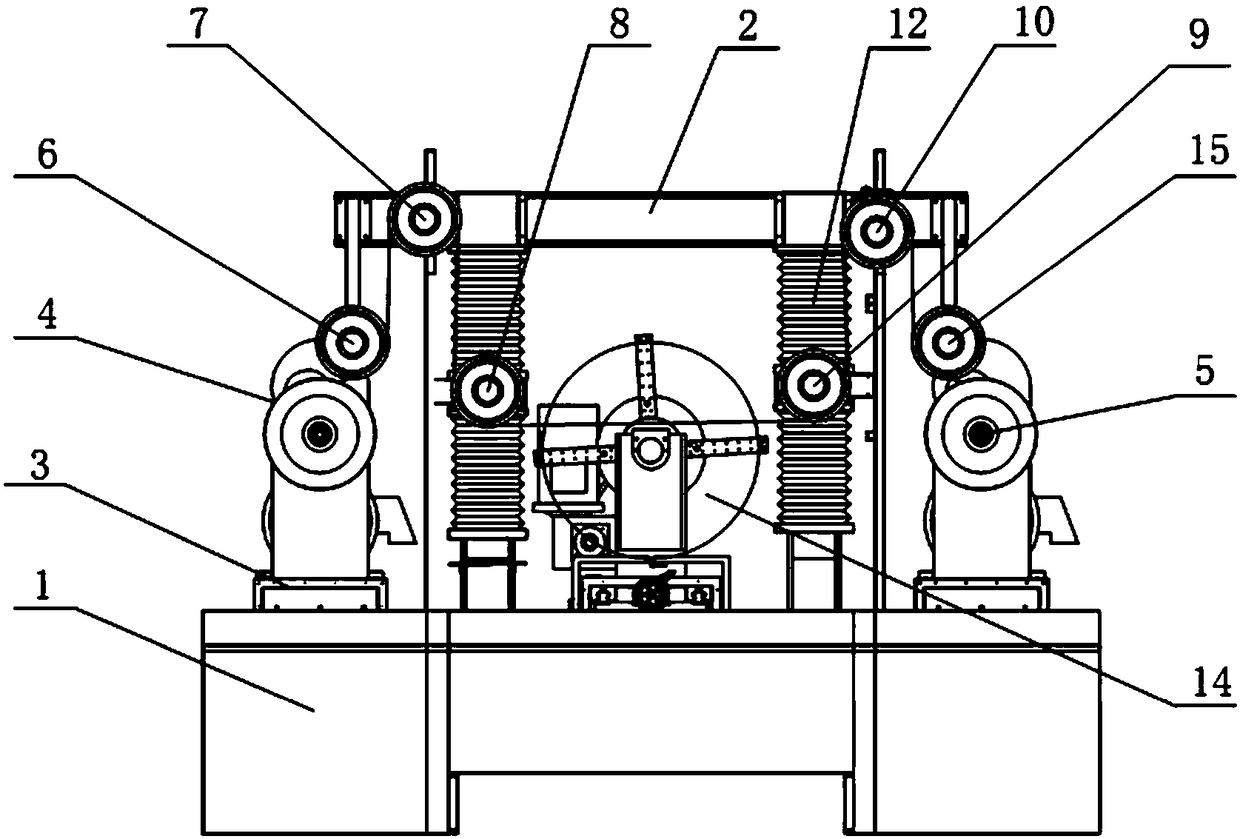

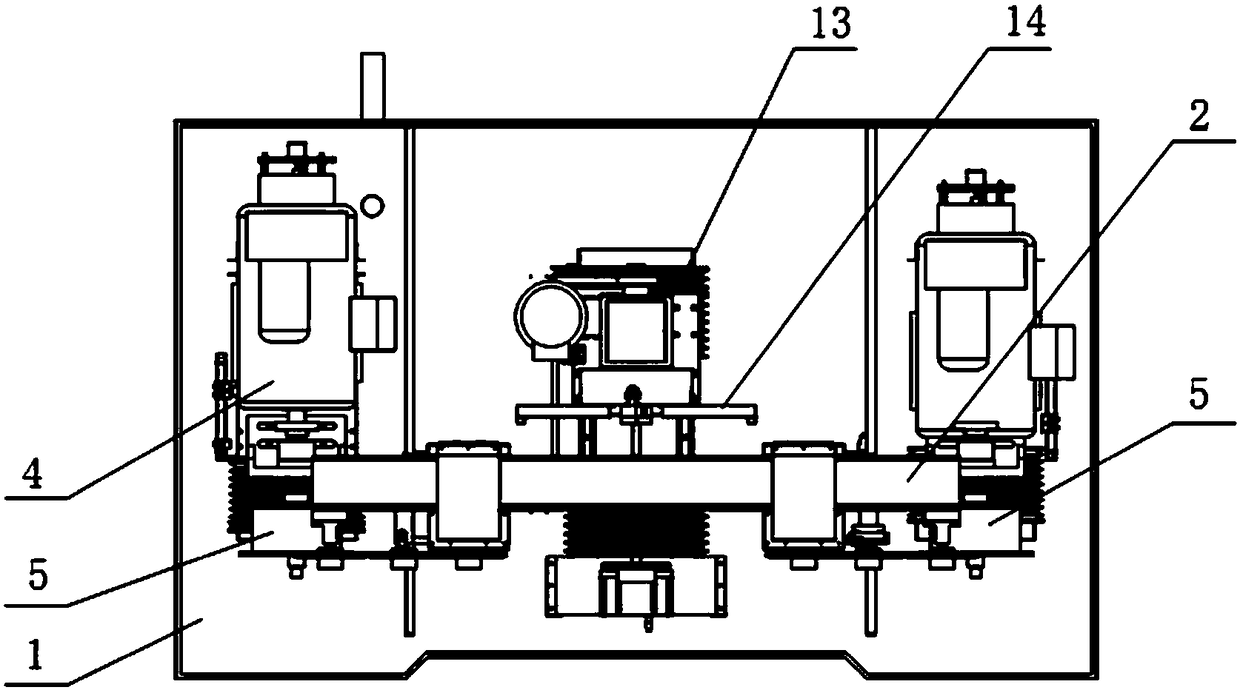

[0022] Such as Figure 1-3 As shown, a diamond wire cutting machine includes a base 1, a frame 2, a workpiece clamping device, a cutting wire assembly, and a lifting mechanism. The frame 2 and the workpiece clamping device are arranged on the base 1, the cutting wire of the cutting wire assembly performs wire cutting on the workpiece on the workpiece clamping device, and the lifting mechanism is used to adjust the distance between the cutting wire and the workpiece.

[0023] The lifting mechanism comprises two lifting columns 12 . Lifting columns 12 are arranged on both sides of the workpiece clamping device.

[0024] Such as figure 1 , 4 As shown, the cutting wire assembly includes two take-up and take-up reels 5, and the take-up and take-off reels 5 are I-shaped reels. Between the two take-up and pay-off reels 5 are respectively provided with a first wire reel 6, a meter wheel 7, a first oscillating wire reel 8, a second oscillating wire reel 9, a broken wire induction w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com