Novel ultra-high-pressure flexible semi-wet process for preparing scrimber

An ultra-high pressure, semi-wet technology, applied in the direction of manufacturing tools, wood processing appliances, wood compression, etc., can solve the problems of poor aging resistance of finished reconstituted wood profiles, increased production costs of reconstituted wood, loss of moisture from wood fibers, etc. Achieve the effect of improving anti-aging performance, reducing the possibility of water loss, and reducing the cost of drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

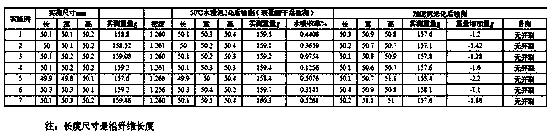

Examples

Embodiment 1

[0033] A new ultra-high pressure flexible semi-wet method for preparing recombined wood, including the following steps: material selection-section-slicing-first drying or drying-weighing and packaging-vacuum pressure impregnation-low temperature heating modification- Ultra-high pressure flexible compression molding - curing - demoulding - trimming - inspection - storage;

[0034] The porcelain bamboo in Guangdong is selected as raw material. The porcelain bamboo was felled one day ago. The specifications are: the growth period is 3 years, the diameter is 25mm, there is no serious moth, no mildew and deterioration;

[0035] Remove bamboo green and bamboo yellow after cutting section 3000mm processing, then slice, bamboo material obtains thickness 2mm, width 10mm thin bamboo chips after sectioning, sectioning processing;

[0036] After the first drying or drying treatment, the moisture content of the bamboo chips is: 3%≤moisture content≤15%, with an average moisture content of 9...

Embodiment 2

[0042]A new ultra-high pressure flexible semi-wet method for preparing recombined wood, including the following steps: material selection-section-slicing-first drying or drying-weighing and packaging-vacuum pressure impregnation-low temperature heating modification- Ultra-high pressure flexible compression molding - curing - demoulding - trimming - inspection - storage;

[0043] Choose Cizhu from Sichuan as raw material. The Cizhu was felled 2 days ago. The specifications are: 4 years in growth period, 80mm in diameter, no serious insects, no mildew and deterioration;

[0044] Remove bamboo green and bamboo yellow after section 3200mm is processed, and then slice, and bamboo material obtains thin bamboo chips with thickness 2.5mm and width 25mm after sectioning and sectioning;

[0045] After the first drying or drying treatment, the moisture content of the bamboo chips is: 3%≤moisture content≤15%, with an average moisture content of 8%;

[0046] During the vacuum pressure imp...

Embodiment 3

[0051] A new ultra-high pressure flexible semi-wet method for preparing recombined wood, including the following steps: material selection-section-slicing-first drying or drying-weighing and packaging-vacuum pressure impregnation-low temperature heating modification- Ultra-high pressure flexible compression molding - curing - demoulding - trimming - inspection - storage;

[0052] The moso bamboo from Hunan that was felled 1 day ago was selected as the raw material. The specifications are: the growth period is 6 years, the diameter is 120mm, there is no serious moth, no mildew and deterioration;

[0053] Remove bamboo green and bamboo yellow after the section processing, and then slice, and the bamboo material obtains thin bamboo slices with a thickness of 1mm and a width of 10mm after sectioning and sectioning;

[0054] After the first drying or drying treatment, the moisture content of the bamboo chips is: 3%≤moisture content≤15%, with an average moisture content of 10%;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com