Four-level food grinding smashing high speed blender

A cooking machine and food technology, which is applied to household appliances, applications, kitchen utensils, etc., can solve the problems of unreasonable tool structure design, poor wall-breaking effect, low wall-breaking efficiency, etc., to prevent heat loss and limit position Stable and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

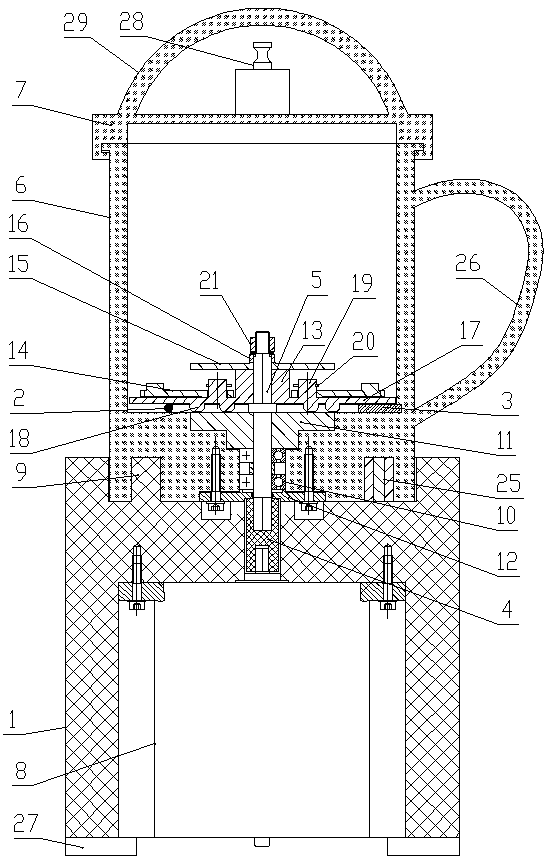

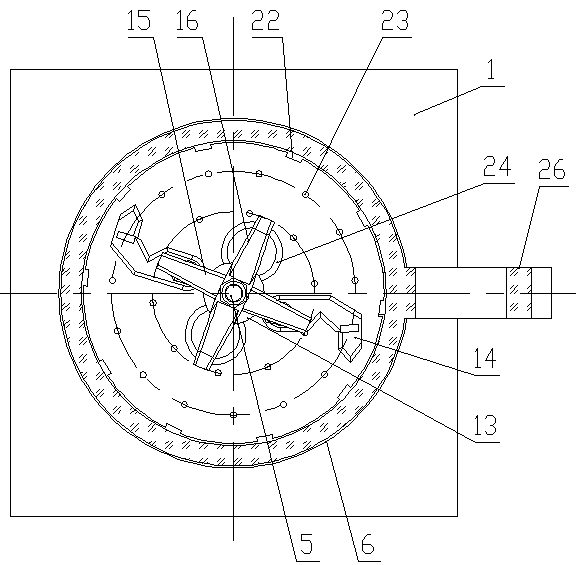

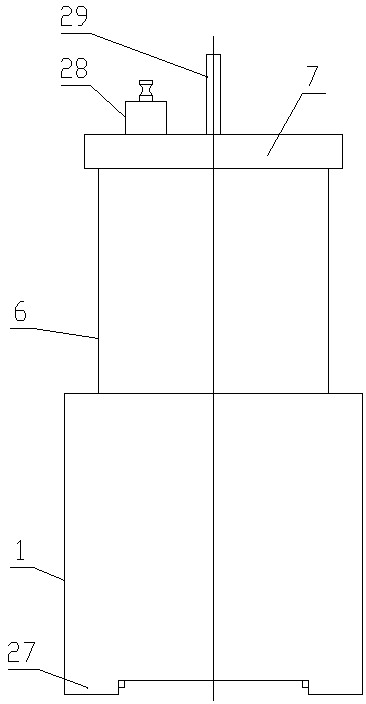

[0034] Such as Figure 1-Figure 6 As shown, the four-stage grinding and crushing food type broken wall cooking machine of the present invention includes a base 1, an electric heater 2, an anti-dry heating electrode 3, a temperature sensor, a rotating shaft 5, a cup body 6, a cup cover 7, a motor 8 and four The top of the base 1 is provided with a circular placement groove, the bottom of the base 1 is provided with an installation groove, the motor 8 is arranged in the installation groove and the main shaft of the motor 8 is vertically upward, and the placement groove is set in a limited direction along the vertical direction. The positioning column 9, the cup body 6 is provided with a limit groove corresponding to the limit column 9, the bottom of the cup body 6 is set in the placement groove and the limit column 9 is inserted into the limit groove correspondingly, and the cup cover 7 is fastened on the cup body 6 top;

[0035] The base 1 is provided with an up and down trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com