SIOx-based compound cathode material for lithium ion batteries and preparation method of material

A technology for lithium-ion batteries and negative electrode materials, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of volume expansion, poor conductivity of silicon oxide particles, and poor cycle performance, so as to reduce irreversible capacity loss, The process conditions are easy to control and the effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

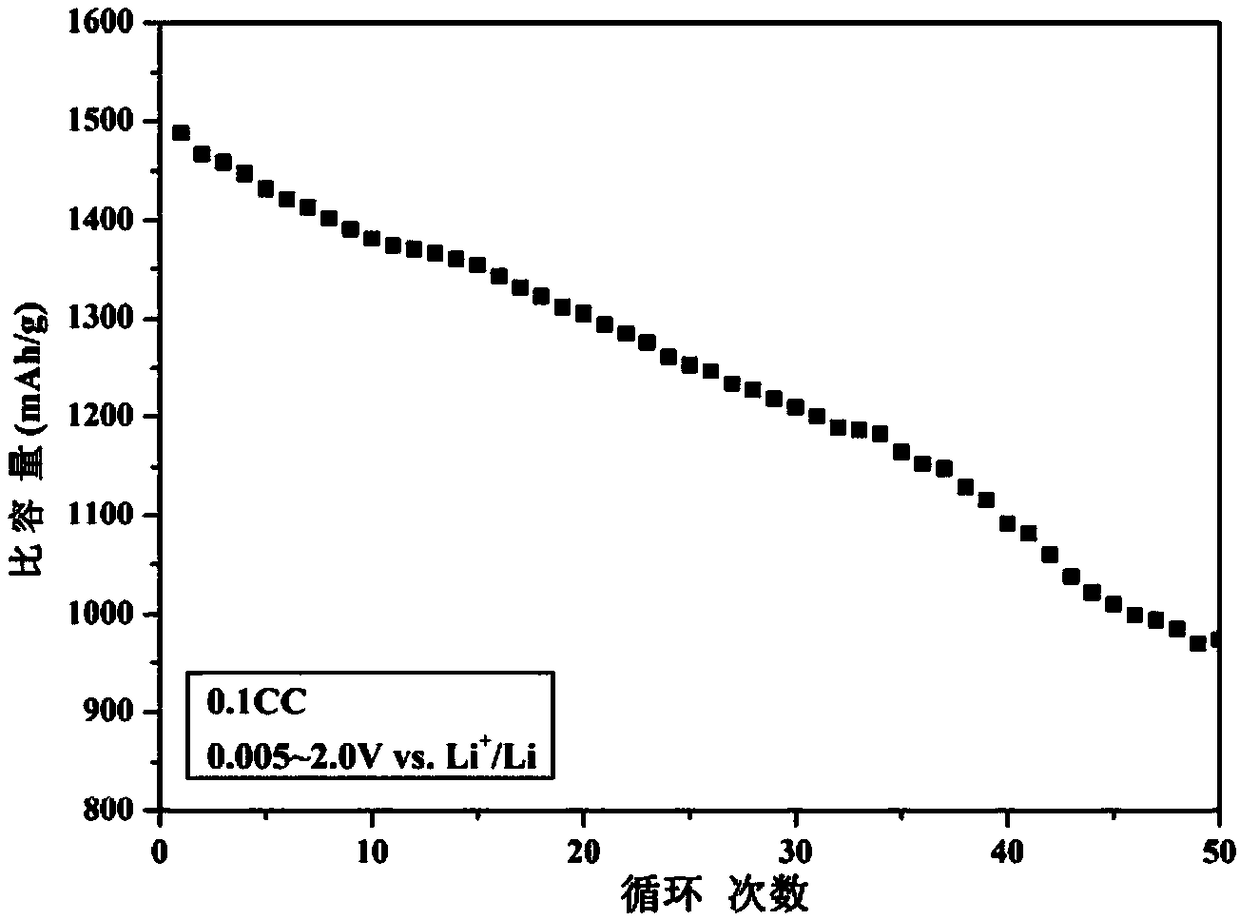

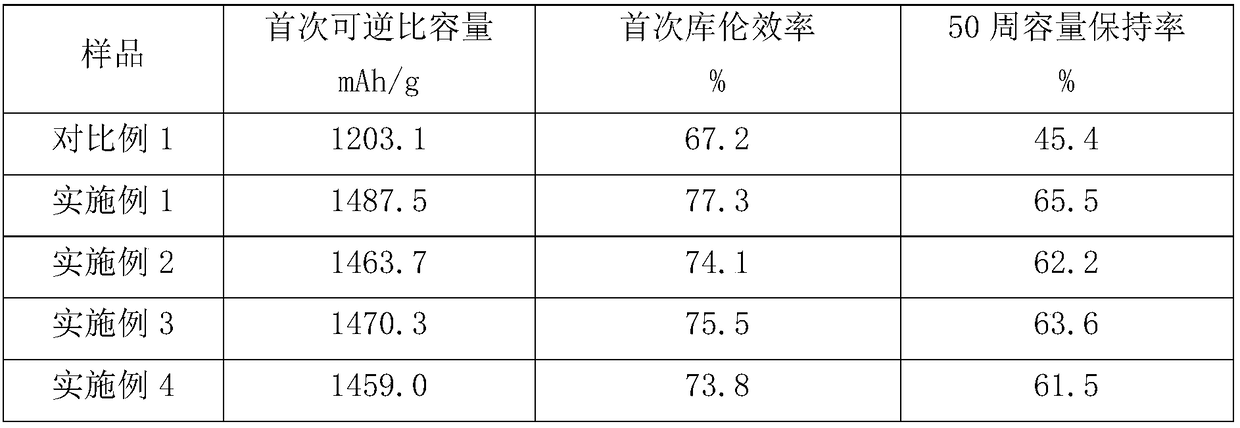

Image

Examples

Embodiment 1

[0031] A kind of SiO x The preparation method of the base composite negative electrode material includes the following steps:

[0032] 1) Mix 200g of the silica raw material with a median particle size of 5um and 400g of absolute ethanol uniformly, and then use a nano ball mill for ball milling to a median particle size of 500nm to obtain a slurry;

[0033] 2) Take 6g of aluminum isopropoxide and dissolve it with 30g of absolute ethanol, and add it to the slurry, stir and mix evenly;

[0034] 3) Spray drying the slurry with an inlet temperature of 120°C to obtain powder;

[0035] 4) The powder is roasted in a nitrogen atmosphere, the heating rate is 5°C / min, and the temperature is raised to 1000°C for 6 hours to obtain a primary roasted material;

[0036] 5) Airflow crushing of the primary roasted material, the median particle size after crushing is 2um;

[0037] 6) Stir and mix 100g of the crushed material with 10g of asphalt, 5g of polyvinylpyrrolidone and 150g of absolute ethanol, and...

Embodiment 2

[0048] A kind of SiO x The preparation method of the base composite negative electrode material includes the following steps:

[0049] 1) Mix 200g of silica raw material with a median particle size of 5um and 400g of absolute ethanol uniformly, and then ball mill with a nano ball mill to achieve a median particle size of 800 nm to obtain a slurry;

[0050] 2) Take 8.5 g of magnesium acetate and dissolve it in 30 g of deionized water, and add it to the slurry, stir and mix evenly;

[0051] 3) Spray drying the slurry with an inlet temperature of 120°C to obtain powder;

[0052] 4) The powder is roasted in a nitrogen atmosphere, the heating rate is 5°C / min, and the temperature is raised to 1000°C for 6 hours to obtain the primary roasted material;

[0053] 5) Airflow crushing of the primary roasted material, the median particle size after crushing is 2.5um;

[0054] 6) Stir and mix 100 g of the crushed material with 10 g of asphalt, 20 g of polyethylene glycol and 150 g of absolute ethanol,...

Embodiment 3

[0057] A kind of SiO x The preparation method of base composite negative electrode material includes the following steps:

[0058] 1) Mix 200g of the silica raw material with a median particle size of 3um and 300g of absolute ethanol uniformly, and then use a nano ball mill for ball milling to a median particle size of 500nm to obtain a slurry;

[0059] 2) Take 5.5 g of calcium acetate and dissolve it in 30 g of deionized water, and add it to the slurry, stir and mix evenly;

[0060] 3) Spray drying the slurry with an inlet temperature of 150°C to obtain powder;

[0061] 4) The powder is roasted in a nitrogen atmosphere, the heating rate is 5°C / min, and the temperature is raised to 1000°C for 2 hours to obtain a primary roasted material;

[0062] 5) Airflow crushing of the primary roasted material, the median particle size after crushing is 1um;

[0063] 6) Stir and mix 100 g of the crushed material with 10 g of sucrose, 8 g of polyvinyl alcohol and 150 g of absolute ethanol, and then st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com