Dielectric geometric phase metasurface material with low depth-to-width ratio and structural optimization method thereof

A dielectric and metasurface technology, applied in the field of micro-nano optics, can solve the problems of inability to guarantee device yield and mass production, inability to guarantee minimum process error requirements, lack of development ideas, etc., achieving continuous geometric phase adjustment function, easy to promote The effect of production, yield and mass production assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to illustrate the present invention and / or the technical solutions in the prior art more clearly, the embodiments of the present invention will be described below with reference to the accompanying drawings. Obviously, the drawings in the following description are only some embodiments of the present invention, and those skilled in the art can obtain other drawings based on these drawings and obtain other implementations.

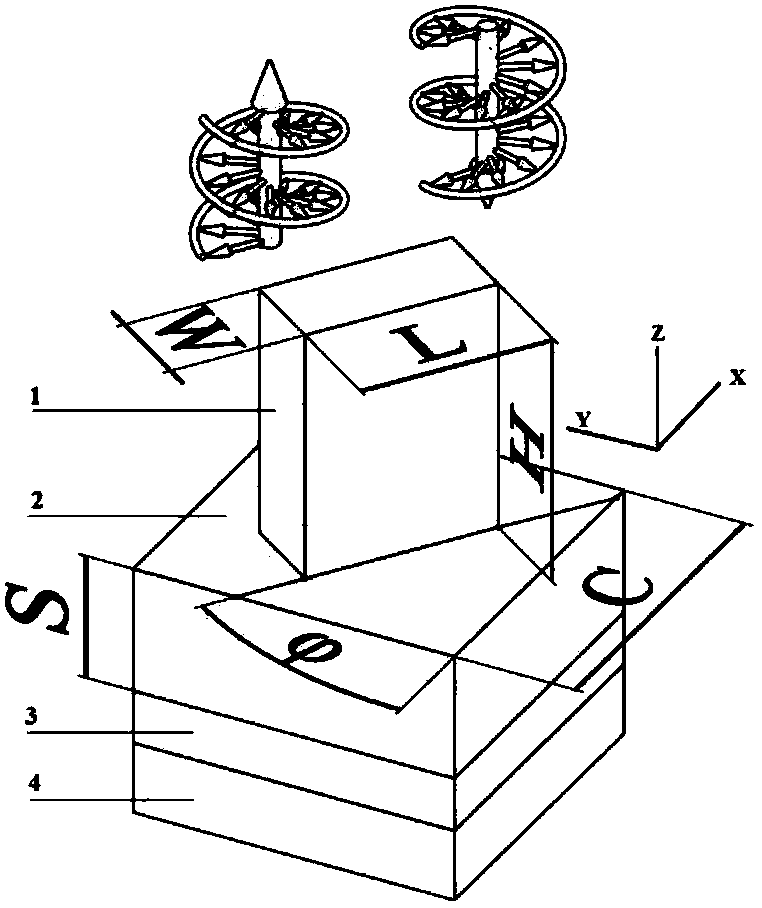

[0040] see figure 1 , is shown as a structural schematic diagram of the dielectric geometric phase metasurface material of the present invention, the dielectric geometric phase metasurface material shown includes a substrate 4, a reflective layer 3 on the substrate 4, an F-P layer 2 on the reflective layer 3, and an F-P layer arranged on the F-P The dielectric nano-brick array on the layer 2 is composed of a number of dielectric nano-bricks 1 uniformly arranged in the same size, and the dielectric nano-brick 1 is in the shape of a cuboid. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com