Micro-channel two-phase flow radiator test device

A testing device and microchannel technology, applied in the direction of measuring devices, testing of machines/structural components, instruments, etc., can solve problems such as inability to directly observe changes in two-phase flow patterns and bubbles, complicated device structure, and limited technology , to achieve the effect of easy judgment of working fluid state, wide application range, and not easy to leak liquid and gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

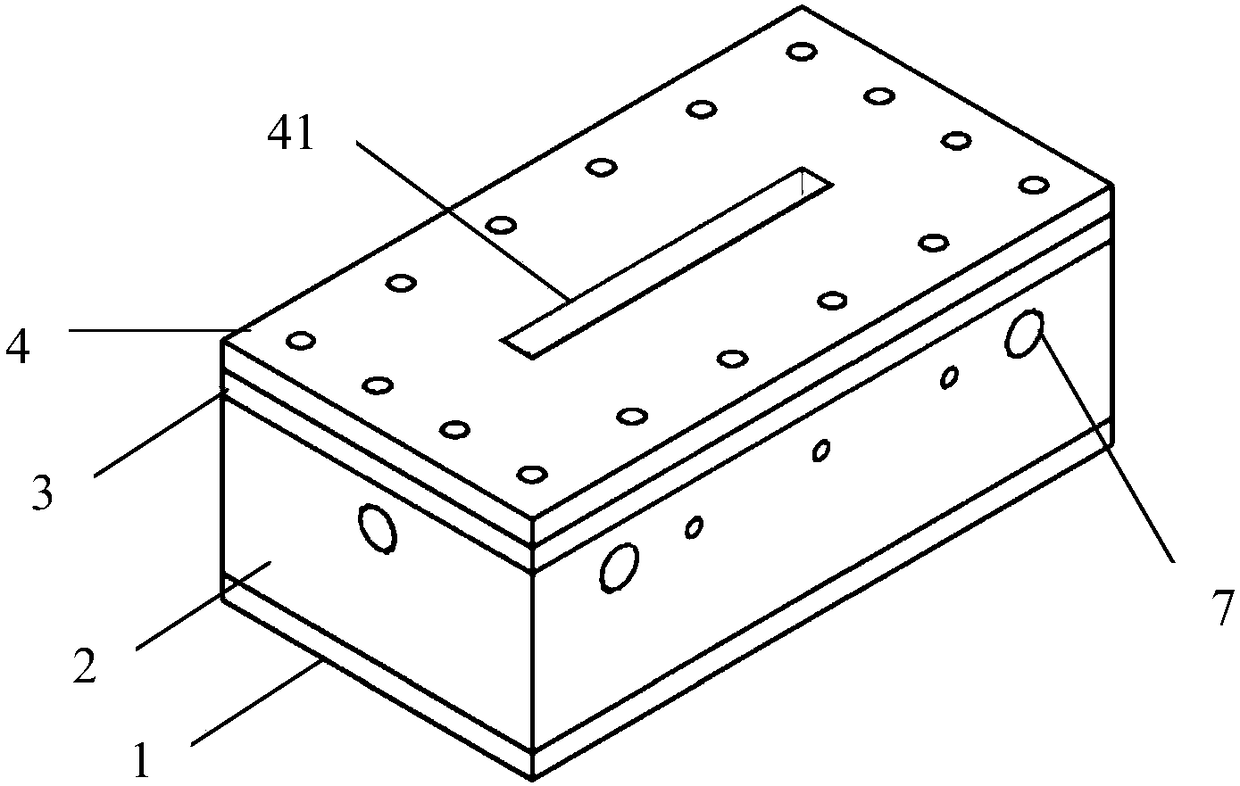

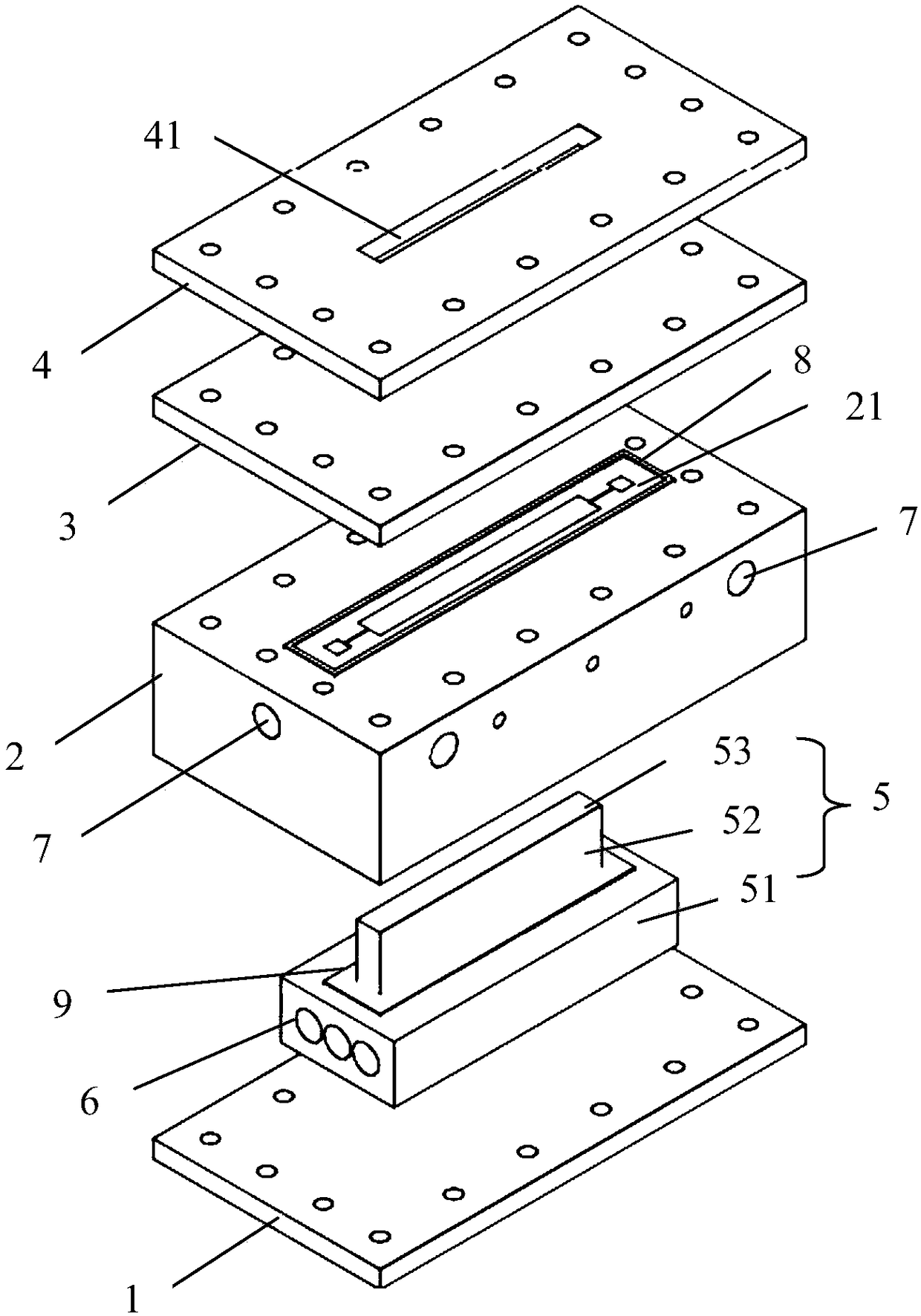

[0023] Such as figure 1 , figure 2 As shown, a kind of microchannel two-phase flow radiator testing device described in the present invention comprises bottom plate 1, glass fiber reinforced plastic cavity 2, transparent glass plate 3 and cover plate 4 that are interconnected successively from bottom to top, and described bottom plate 1 and A metal block assembly 5 is provided inside the cavity formed by the glass fiber reinforced plastic cavity 2, and a heating rod device 6 is provided inside the metal block assembly 5, and the metal block assembly 5 includes a lower metal block 51, an upper metal block 52 and a microchannel 53 , the microchannel 53 is placed on the top of the upper metal block 51 , and the heating rod device 6 crosses two opposite sides of the lower metal block 51 . The middle part of the FRP cavity 2 is provided with an open groove 21, the shape of the open groove 21 is adapted to the shape of the flow path of the microchannel 53, and the open groove 21 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com