Oil-gas separation device for automobile refrigeration system

A technology of refrigeration system and separation device, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as failure to achieve oil separation efficiency, inability to achieve separation well, and increase flow rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

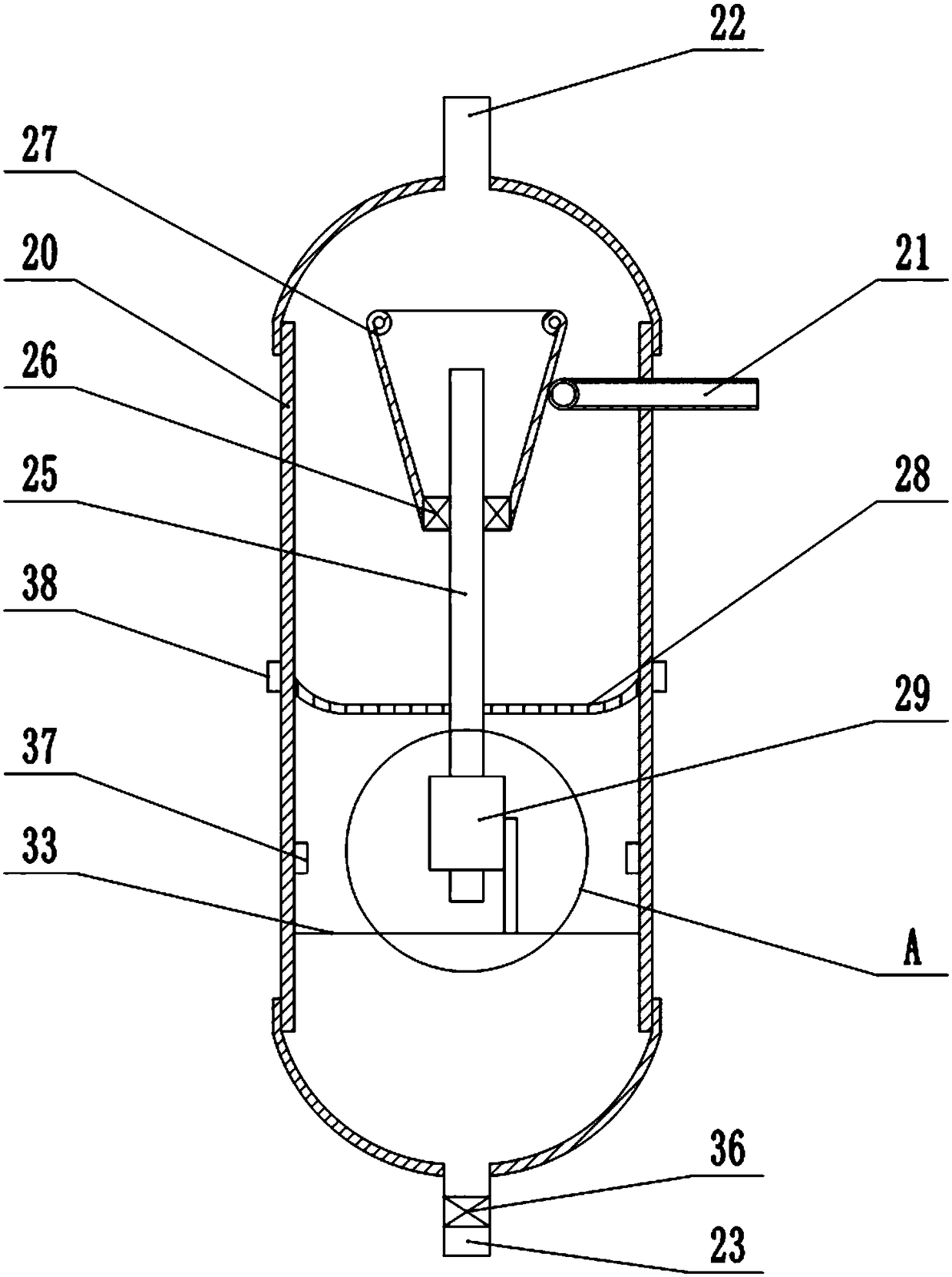

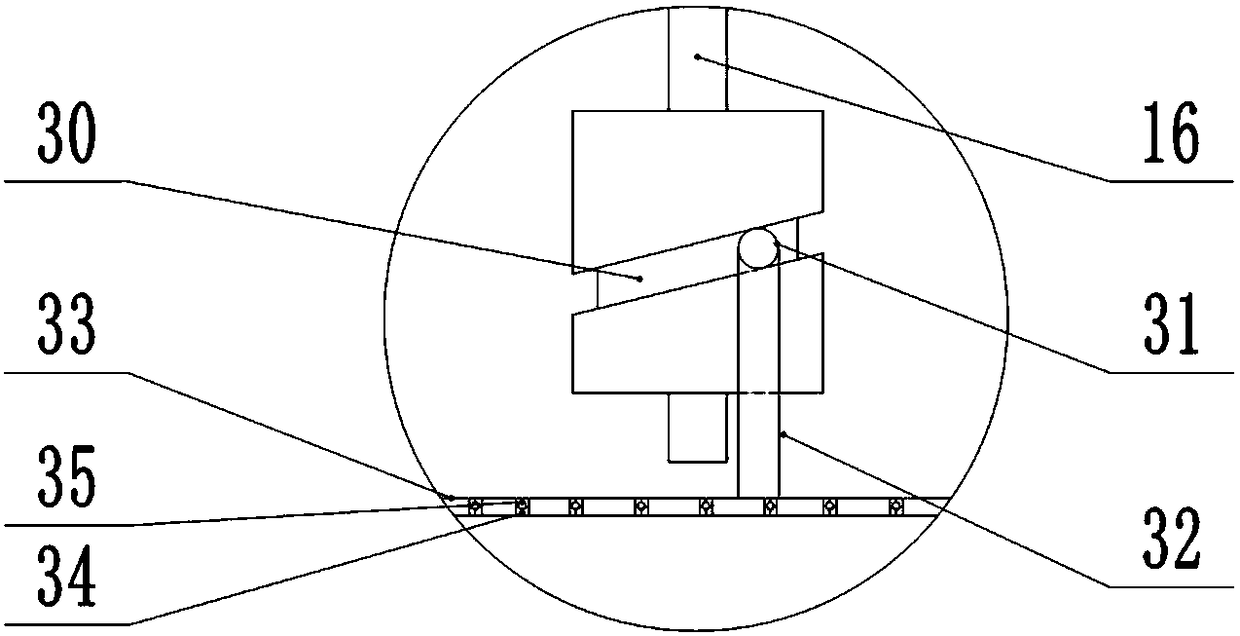

[0022] Further detailed explanation through specific implementation mode below:

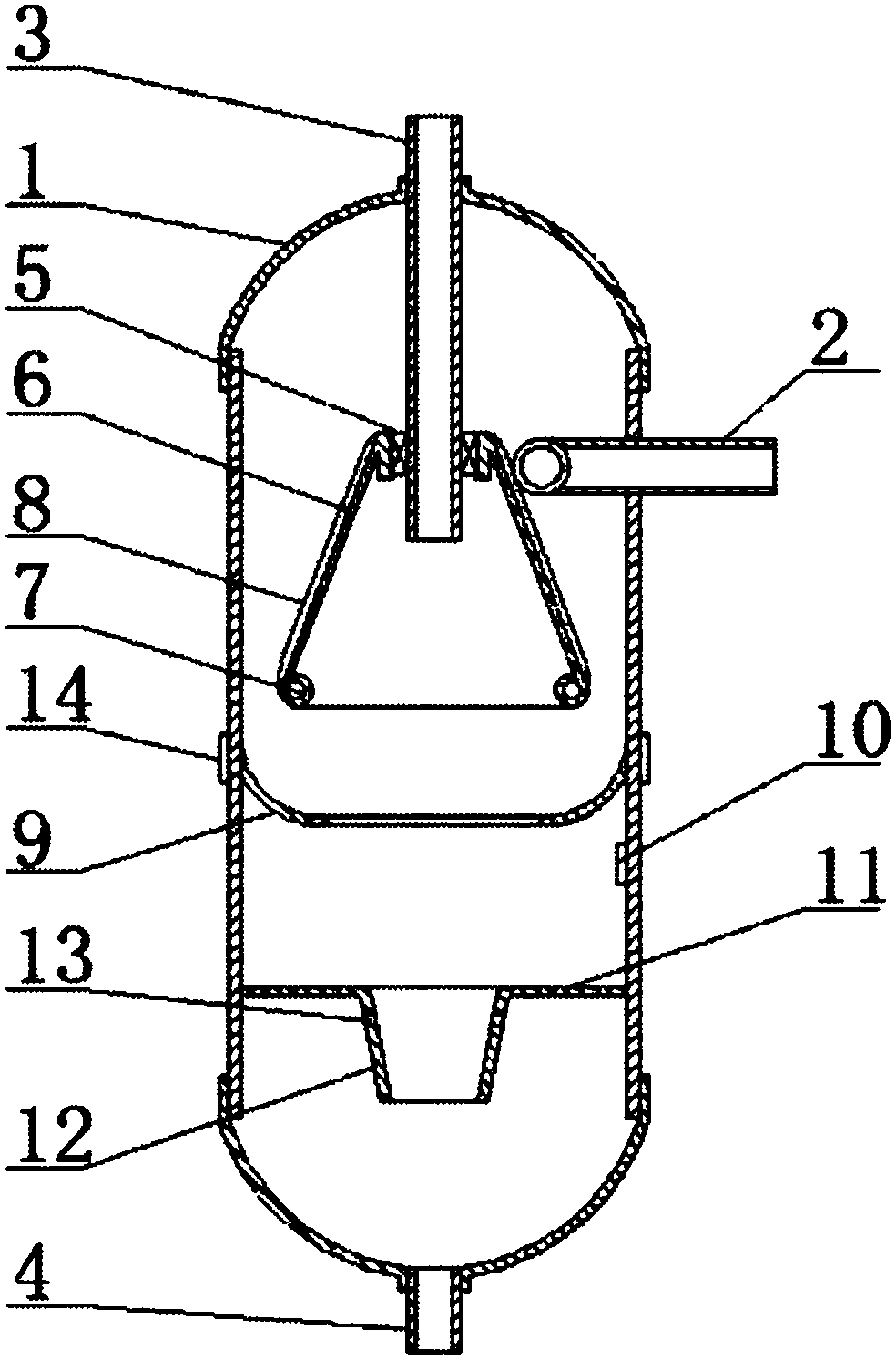

[0023] The reference signs in the accompanying drawings of the description include: housing 20, air intake pipe 21, air outlet pipe 22, oil return pipe 23, shaft 25, bearing 26, sleeve 27, filter plate 28, cylindrical cam 29, curved groove 30, Slide block 31, pin shaft 32, floating plate 33, through hole 34, oil inlet check valve 35, oil outlet check valve 36, liquid level gauge 37, positioning plate 38, sound-absorbing layer 39.

[0024] Such as figure 2 As shown, the oil-gas separation device of the automobile refrigeration system includes an air inlet pipe 21, an air outlet pipe 22, an oil return pipe 23 and a cylindrical housing 20, a circle of positioning plates 38 are arranged on the outer wall of the cylindrical housing 20, and the air outlet pipe 22 is located on At the center of the top of the housing 20, the air inlet pipe 21 is arranged on the side wall of the upper part of the housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com