High-hardness butyronitrile rubber material for preventing scorching and preparation method thereof

A nitrile-butadiene rubber, high-hardness technology, applied in the rubber field, can solve problems such as early scorch, and achieve the effects of avoiding scorch, shortening dispersion time, and preventing scorch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

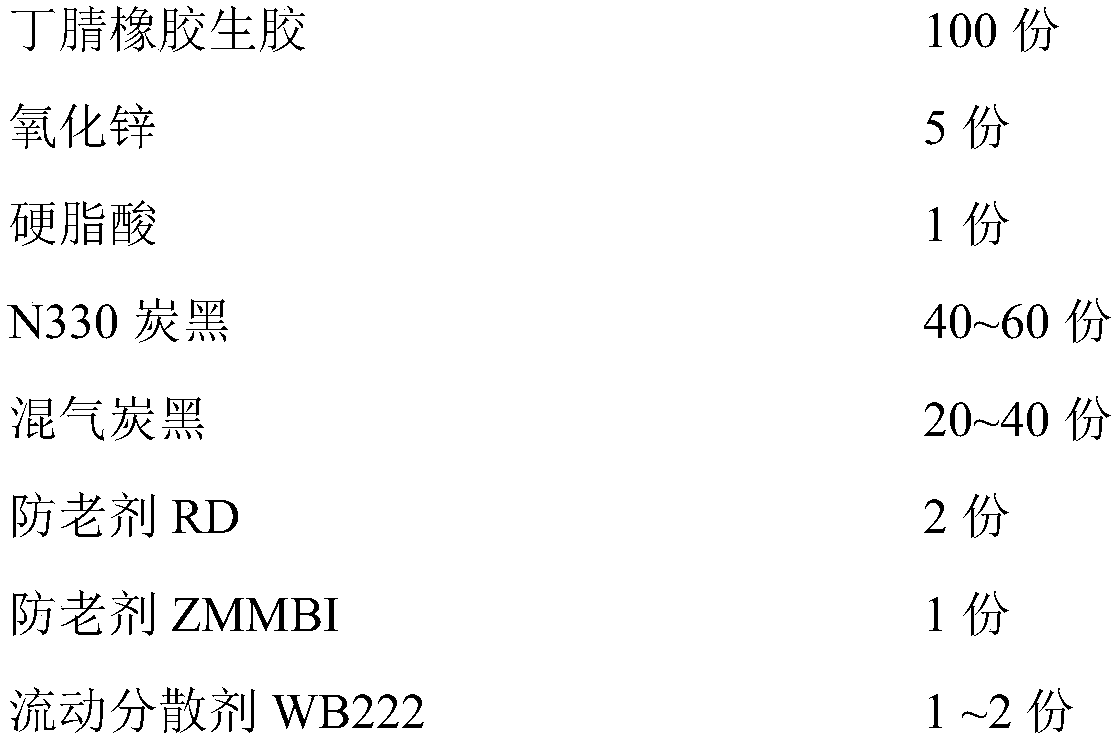

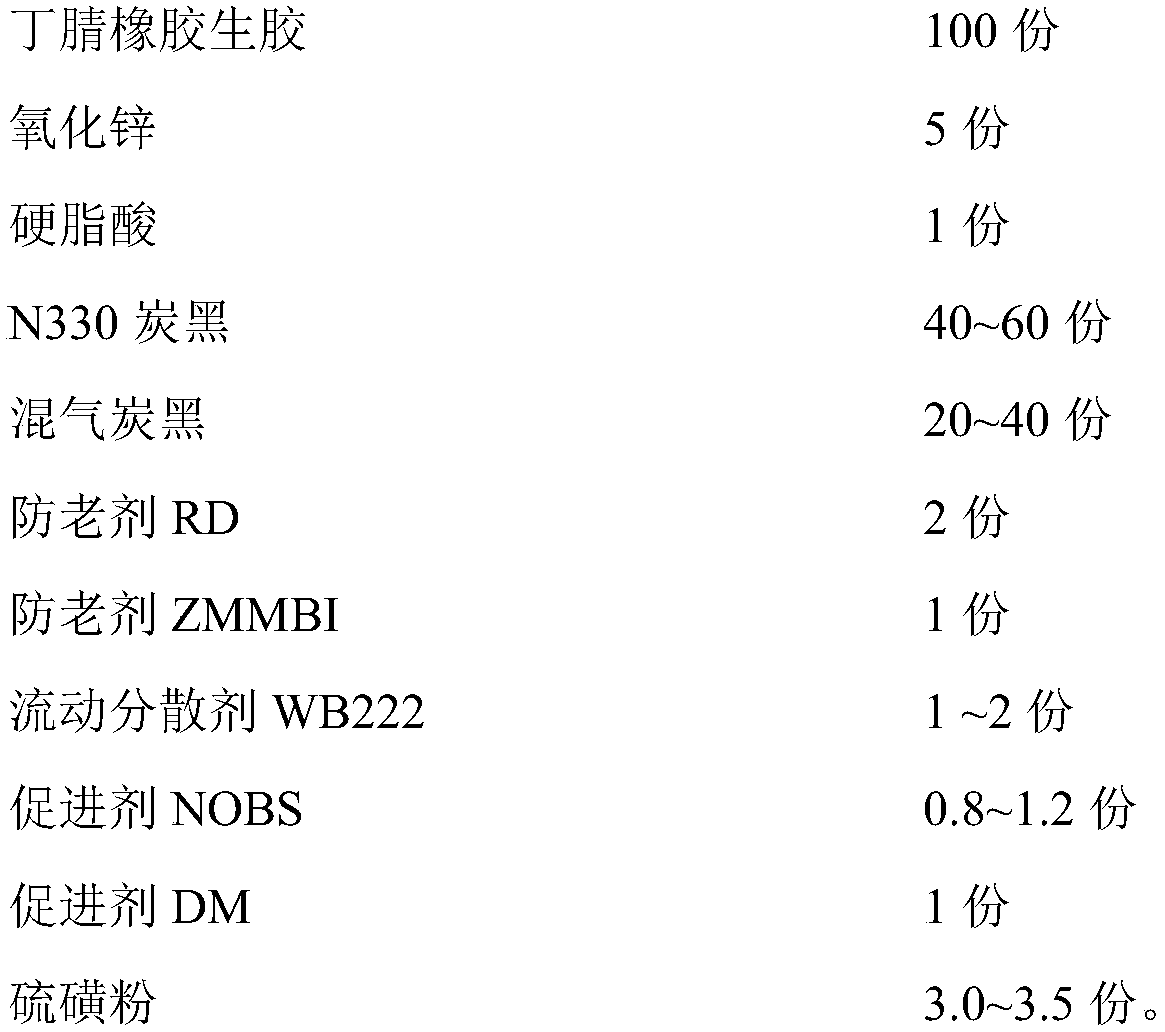

[0035] A kind of anti-scorch high hardness nitrile rubber material of the present embodiment comprises following components:

[0036] 100 parts of nitrile rubber raw rubber, 5 parts of zinc oxide, 1 part of stearic acid, 60 parts of N330 carbon black, 20 parts of aerated carbon black, 2 parts of anti-aging agent RD, 1 part of anti-aging agent ZMMBI, 2 parts of flowable dispersant WB222 , accelerator NOBS 1.2 parts, accelerator DM 1 part, sulfur powder 3.0 parts.

[0037] The high hardness nitrile rubber material process of present embodiment preparation anti-scorch is:

[0038] Step 1. Masterbatch mixing: 100 parts of nitrile rubber raw rubber, 5 parts of zinc oxide, 1 part of stearic acid, 20 parts of aerated carbon black, 2 parts of anti-aging agent RD, 1 part of anti-aging agent ZMMBI, flow dispersion 2 parts of agent WB222, and 0.5 parts of sulfur powder and 60 parts of N330 carbon black, which were uniformly mixed in advance, were sent to the internal mixer for banburyin...

Embodiment 2

[0043] A kind of anti-scorch high hardness nitrile rubber material of the present embodiment comprises following components:

[0044] 100 parts of nitrile rubber raw rubber, 5 parts of zinc oxide, 1 part of stearic acid, 40 parts of N330 carbon black, 40 parts of aerated carbon black, 2 parts of anti-aging agent RD, 1 part of anti-aging agent ZMMBI, 2 parts of mobile dispersant WB222 , 1 part of accelerator NOBS, 1 part of accelerator DM, 3.2 parts of sulfur powder.

[0045] The high hardness nitrile rubber material process of present embodiment preparation anti-scorch is:

[0046] Step 1. Masterbatch mixing: 100 parts of nitrile rubber raw rubber, 5 parts of zinc oxide, 1 part of stearic acid, 40 parts of aerated carbon black, 2 parts of anti-aging agent RD, 1 part of anti-aging agent ZMMBI, flow dispersion 2 parts of agent WB222, and 0.5 parts of sulfur powder and 40 parts of N330 carbon black, which were uniformly mixed in advance, were sent to the internal mixer for banbu...

Embodiment 3

[0051] A kind of anti-scorch high hardness nitrile rubber material of the present embodiment comprises following components:

[0052] 100 parts of nitrile rubber raw rubber, 5 parts of zinc oxide, 1 part of stearic acid, 50 parts of N330 carbon black, 30 parts of aerated carbon black, 2 parts of anti-aging agent RD, 1 part of anti-aging agent ZMMBI, 2 parts of flowable dispersant WB222 , accelerator NOBS 0.8 parts, accelerator DM 1 part, sulfur powder 3.5 parts.

[0053] The high hardness nitrile rubber material process of present embodiment preparation anti-scorch is:

[0054] Step 1. Master batch mixing: 100 parts of nitrile rubber raw rubber, 5 parts of zinc oxide, 1 part of stearic acid, 30 parts of aerated carbon black, 2 parts of anti-aging agent RD, 1 part of anti-aging agent ZMMBI, flow 2 parts of dispersant WB222, and pre-mixed uniformly 0.5 parts of sulfur powder and 50 parts of N330 carbon black were sent to the banbury mixer for banburying for 5 minutes. Rubber m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com