Heavy metal borate glass with high v value and low temperature coefficient, preparation method and application

A borate glass and heavy metal technology, applied in the field of heavy metal borate glass, can solve the problems of high temperature dependence, low near-infrared band transmittance, small Verdet constant of diamagnetic magneto-optical glass, etc., and achieve low temperature dependence properties, excellent magnetic and optical properties, and good transmittance in the visible band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

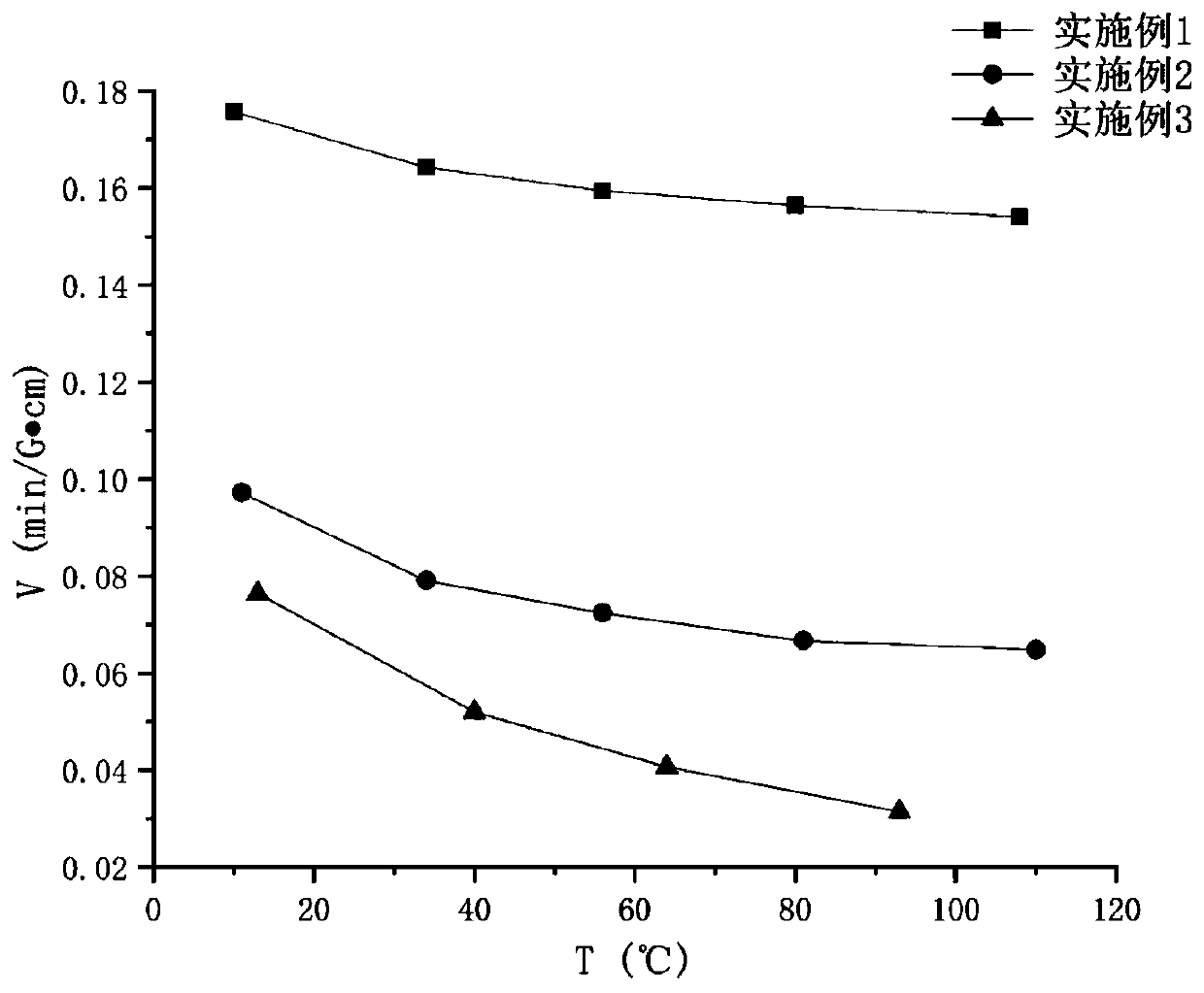

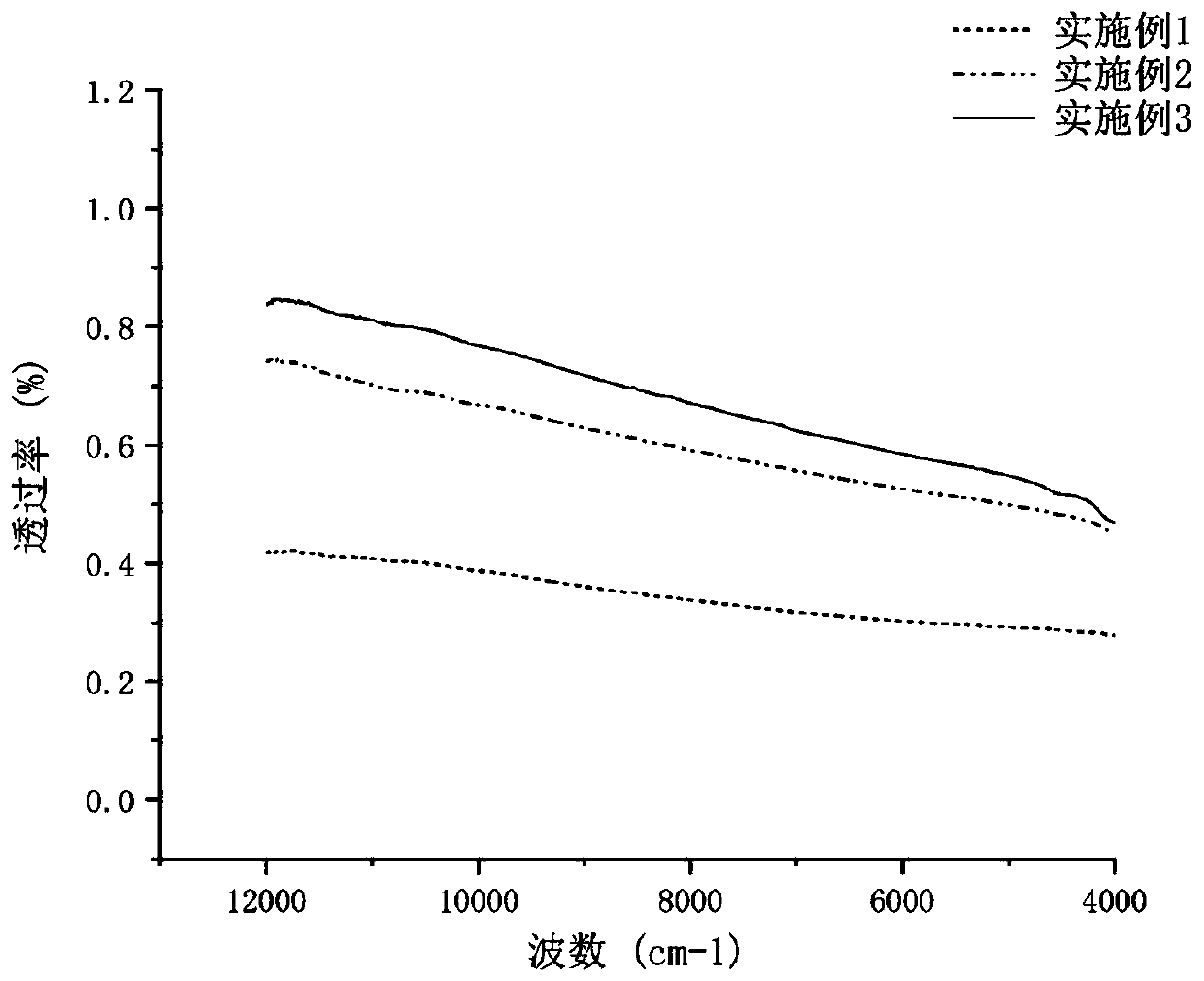

Embodiment 1

[0029] A preparation method of heavy metal borate glass with high magneto-optical performance, the high-purity reagents PbO, H 3 BO 3 and Bi 2 o 3 , calculated according to the formula in row 1 of Table 1, weighed and shaken well to mix, put into a high-purity alumina crucible, heat to 200°C in a muffle furnace and keep it for 20-60min, so that H 3 BO 3 Generate B 2 o 3 , and then heated to 950°C for melting and clarification. At the beginning, heating to a temperature higher than the melting point is to clarify and remove air bubbles. Keep it for 1h and stir, and then cool down to 900°C. At this time, the temperature is lowered to the melting point. The cooling time is faster when pouring. Pour the molten liquid into a mold preheated to 280°C in advance, put it in an annealing furnace at the same temperature for 1.5 hours, then cool it down to room temperature (10-20°C) naturally after power off, and finally use tools to polish the sample and cutting.

[0030] Table 1...

Embodiment 2

[0033] In this example, the composition of the oxides in row 2 in Table 1 is followed, and the preparation process is consistent with Example 1.

Embodiment 3

[0035] In this embodiment, the composition of the oxides in row 3 in Table 1 is followed, and the preparation process is consistent with that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com