Storage transfer robot with internal wireless charging module and automatic wireless charging method of storage transfer robot

A technology for handling robots and wireless charging, applied in charging stations, motor vehicles, electric vehicles, etc., can solve problems such as low work efficiency, slow moving speed, and large footprint, achieve reliable driving, reduce personnel investment, and promote development. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

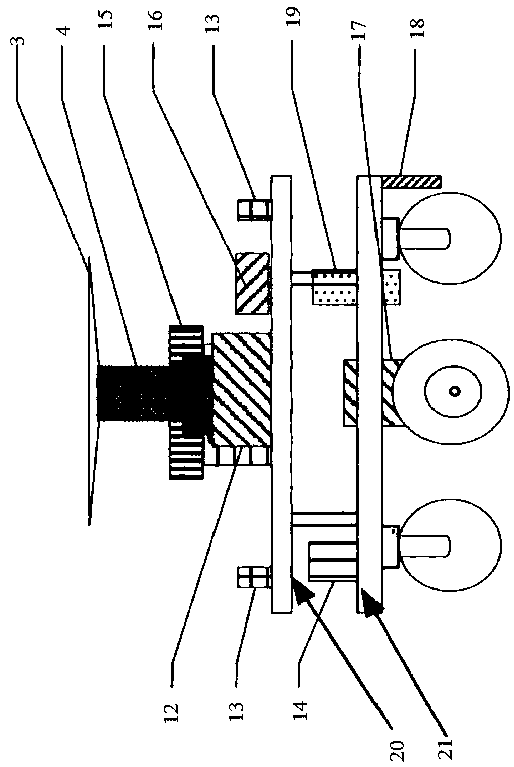

[0030] Please refer to figure 1 , figure 2 with image 3The storage and handling robot with built-in wireless charging module in this specific embodiment adopts an embedded design, including a chassis, a housing, a lifting mechanism, a portable sensor, a charging receiving module and a charging transmitter. Bracket for the object to be transported; the chassis of the handling robot includes the main frame and the bottom plate, which are used to support the overall structure of the robot. The bottom plate is made of steel plates; There are obstacle avoidance device, driving device, navigation and positioning module, control unit, communication unit, lifting mechanism and charging receiving module; the control unit, obstacle avoiding device, lifting mechanism and power supply are placed on the second layer of the main frame, and the driving device, The navigation positioning module and the charging receiving module are placed on the first layer of the main frame; the charging...

Embodiment 2

[0036] A wireless automatic charging method for the storage and handling robot with a built-in wireless charging module in Embodiment 1, specifically comprising the following steps:

[0037] S01: Turn on the main switch of the storage robot, and connect the charging transmitter to the socket;

[0038] S02: The storage handling robot with a built-in wireless charging module automatically monitors the remaining power of the charging receiver. When it detects that the charging receiver of the storage handling robot with a built-in wireless charging The transmitter automatically connects wirelessly. After connection, the electromagnetic wave receiver of the charging receiver receives the electromagnetic wave emitted by the charging transmitter and converts the electromagnetic wave into an electric current. The rectifier rectifies the current and provides electric energy for the storage and handling robot with the built-in wireless charging module;

[0039] S03: When the storage an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com