Powder solid die casting production line

A die-casting molding and assembly line technology, which is applied in the direction of material molding presses, presses, manufacturing tools, etc., can solve problems such as complex production processes, low production efficiency, and potential safety hazards, and achieve good safety, high production efficiency, and automation. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

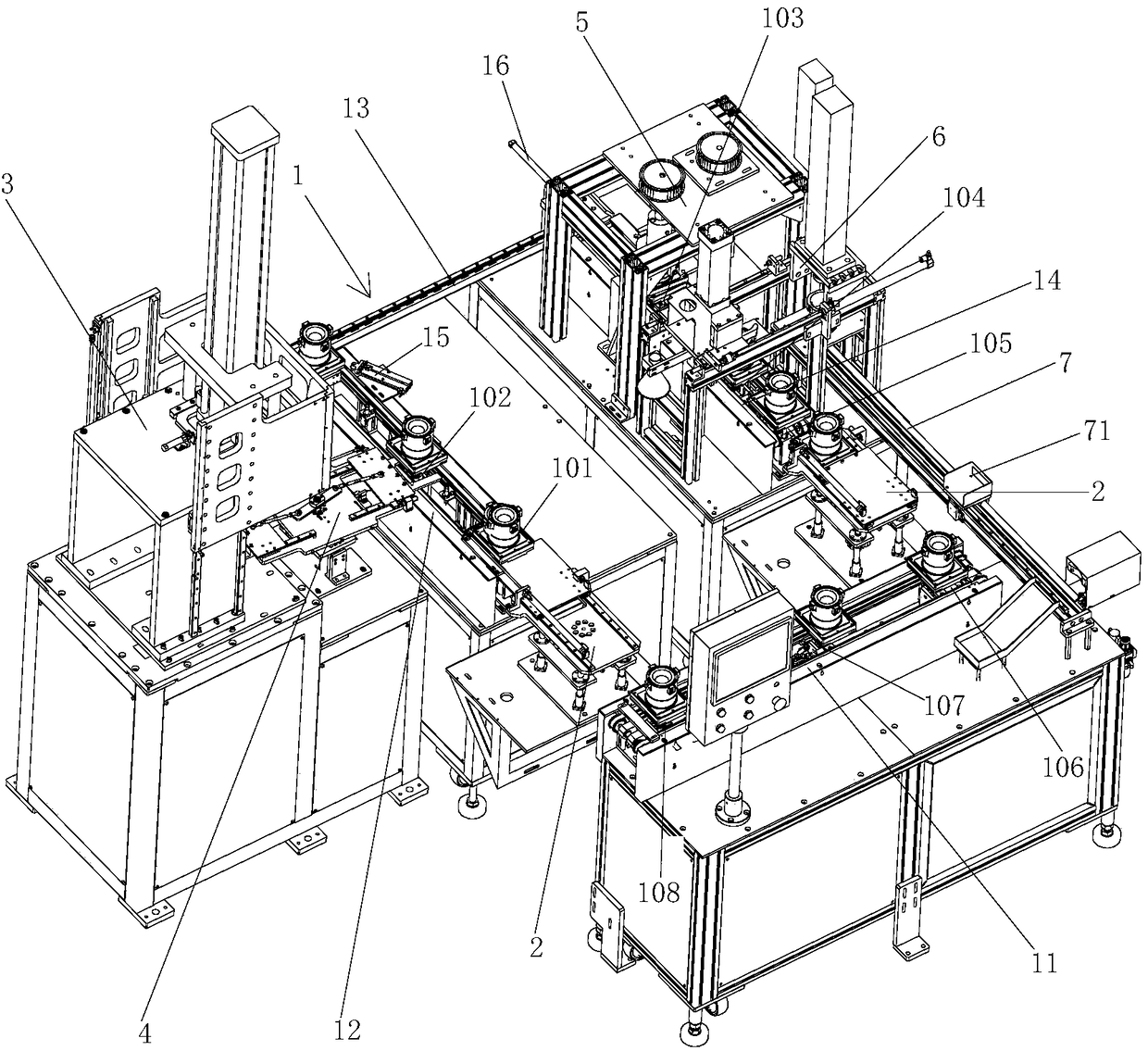

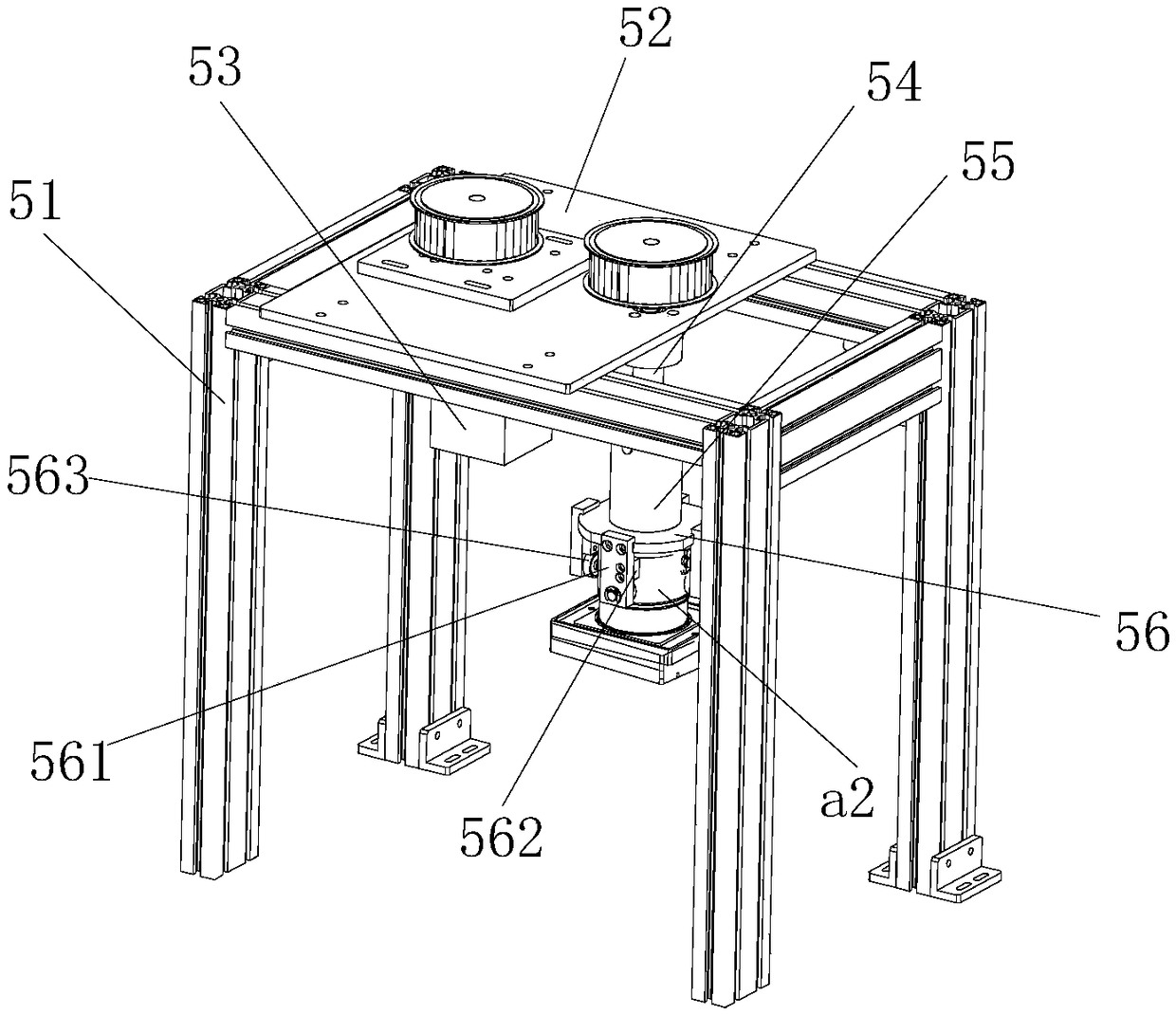

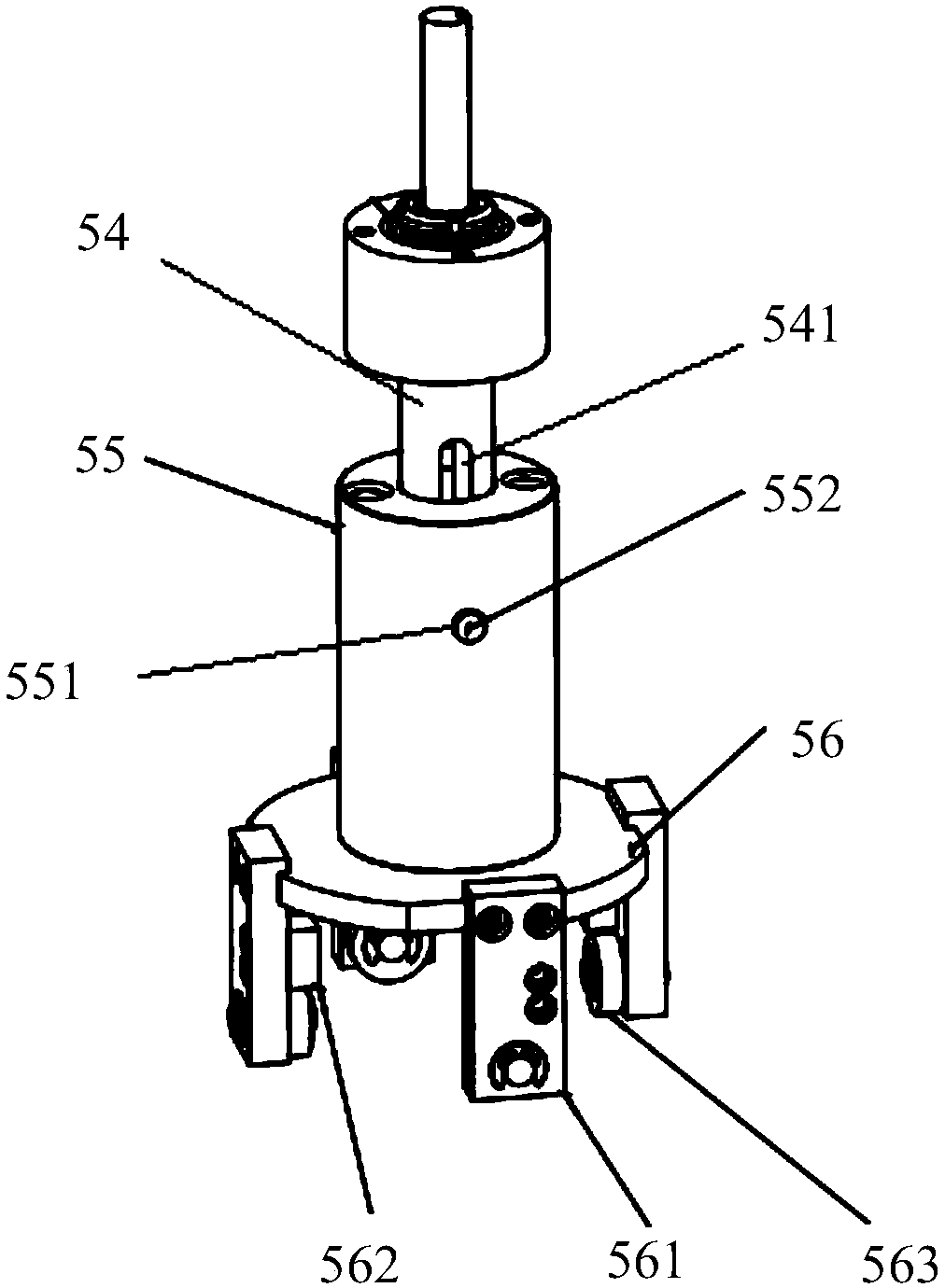

[0024] Such as figure 1 As shown, what is described in this embodiment is a powder solid die-casting molding line, and the mold a used for molding is as follows Figure 9 As shown, it includes a detachable base a1 and a mold cylinder a2 above it. The outer wall of the upper end of the mold cylinder a2 is provided with several wedge-shaped stoppers a3, and the lower surface of the wedge-shaped stopper a3 is provided with a slope a31; wherein:

[0025] The assembly line includes an annular conveying unit 1 composed of a first transverse conveying mechanism 11, a first longitudinal conveying mechanism 12, a second transverse conveying mechanism 13, and a second longitudinal conveying mechanism 14; wherein, the first longitudinal conveying mechanism 12, the second longitudinal conveying mechanism The conveying mechanism 14 is vertically spaced apart f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com