Device for grinding agricultural mechanical steel rings

A technology for agricultural machinery and steel rings, which is applied in the direction of grinding drive devices, grinding machine parts, grinding machines, etc., and can solve the problems of impossibility of consistent grinding marks, high labor intensity, and incomplete grinding of burrs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

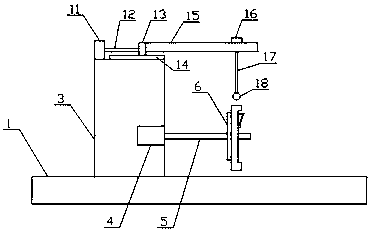

[0018] like Figure 1-2 As shown, the present invention provides a grinding device for steel rings of agricultural machinery, including a base plate 1 and a steel ring 2, a chassis 3 is provided on the top side of the bottom plate 1, a motor 4 is provided in the chassis 3, and the motor 4 One side is connected to the rotating shaft 5, the rotating shaft 5 is provided with a baffle plate 6, one side of the baffle plate 6 is in contact with the steel ring 2, and one side of the baffle plate 6 is provided with a connecting rod 7, and the connecting rod 7 One side is connected with a compression rod 9 through a screw 8, the bottom of the compression rod 9 is connected with a compression block 10, and the top of the chassis 3 is provided with a first cylinder 11, and one side of the first cylinder 11 is connected with the first drive Rod 12, one side of the first driving rod 12 is connected with a push block 13, one side of the first cylinder 11 is provided with a chute 14, the pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com