Steel plate material tailpiece automatic identifying and dispensing system

An automatic identification and material technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of lower production efficiency, waste of production man-hours, and failure to change materials normally in the stamping production line, so as to improve efficiency and ensure reliable product quality controllability and improve the effect of going straight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

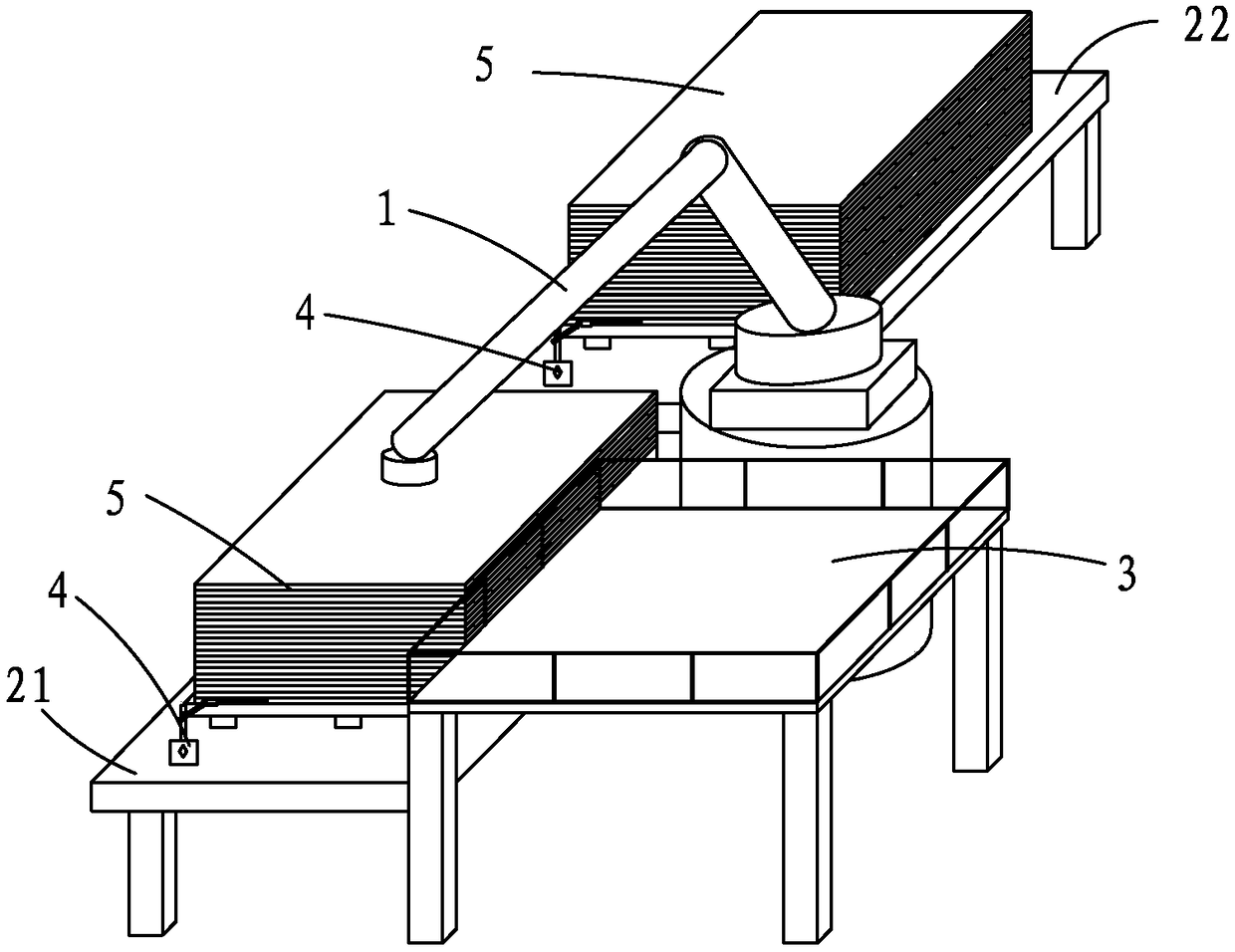

[0012] Such as figure 1 As shown, a system for automatic identification and delivery of finished steel plate materials includes a feeding robot 1, two left and right material trolleys 21, 22, a protective plate collection platform 3, and a PLC circuit (not shown); An end material detector 4 is respectively provided on the trolleys 21 and 22 . Both the feeding robot 1 and the end material detector 4 are connected to the PLC circuit; the left and right material trolleys 21, 22 are stacked with a steel plate 5 to be grabbed by the feeding robot 1, and the bottom of the steel plate 5 is a protection plate; the protection plate 5 is grabbed by the feeding robot 1 to the protection plate collection platform 3 . The waste material detector 4 is arranged under the protective plate 5 stacked on the material trolleys 21 and 22 .

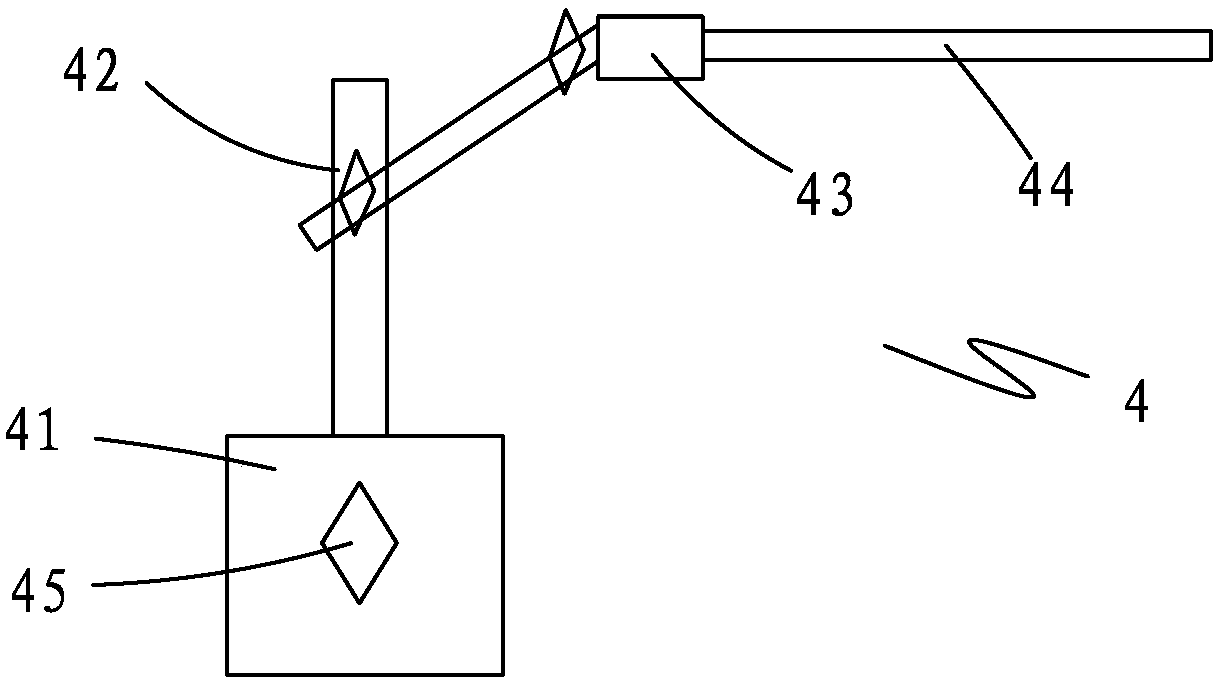

[0013] Such as figure 2 As shown, the end material detector 4 includes a switchable magnetic base 41, a fast fixing bracket 42, a travel switch 43, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com