Method and apparatus for improving water-based negative electrode plate adhesion and cracking

A negative electrode sheet and adhesion technology, which is applied in the field of lithium ion battery electrode sheet preparation, can solve problems such as cracks affecting the negative electrode sheet adhesion, and achieve significant economic value, simple equipment, and avoidance of mistakes and forgetting effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method and device for improving the adhesion and cracks of water-based negative electrode sheets, comprising the following steps:

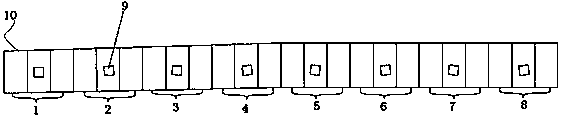

[0030] (1) After the coated electrode piece of the extrusion coating machine enters the coating and drying area 10, the coating and drying area 10 is divided into eight sections, which are respectively marked as the first section 1, the second section 2, and the third section. Section 3, Section IV Section 4, Section V Section 5, Section VI Section 6, Section VII Section 7, Section VIII Section 8, each of which is equipped with a return air outlet 16, and at II2 , Ⅴ5, Ⅵ6 large joints are equipped with an exhaust system;

[0031] (2) Each large section is subdivided into three subsections, each large section is equipped with a return air damper and an exhaust air valve at the first and third subsections, and each large section at the second subsection Each is provided with an observation port 9;

[0032] (3) Reduce the angle of the venti...

Embodiment 2

[0039] After the extrusion coating machine coated electrode piece enters the coating drying area 10, the coating drying area 10 is divided into eight major sections, and the draft air valve angle of the first section of the third section 3 in the coating drying area 10 is Turn it down by 5 degrees, and increase the angle of the exhaust damper of the third section by 10 degrees; increase the angle of the exhaust damper of the first section of the fourth section of the fourth section by 5 degrees; increase the angle of the first section of the fifth section of the fifth section. The angle of the air valve is increased by 10 degrees; at the same time, a humidifying device is installed at the return air outlet 16 of the third, fourth, and fifth sections of the coating drying area 10 to increase the humidity of the return air, and the water storage 11 is passed through the delivery The water pipe I12 is connected to the humidifier 13. When the water level in the humidifier 13 is low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com