Ultrafine plastic mill

A pulverizer and plastic technology, applied in the field of plastic foam processing, can solve the problems of wasting time and manpower, increase production costs, etc., and achieve the effects of saving production costs, high work efficiency, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

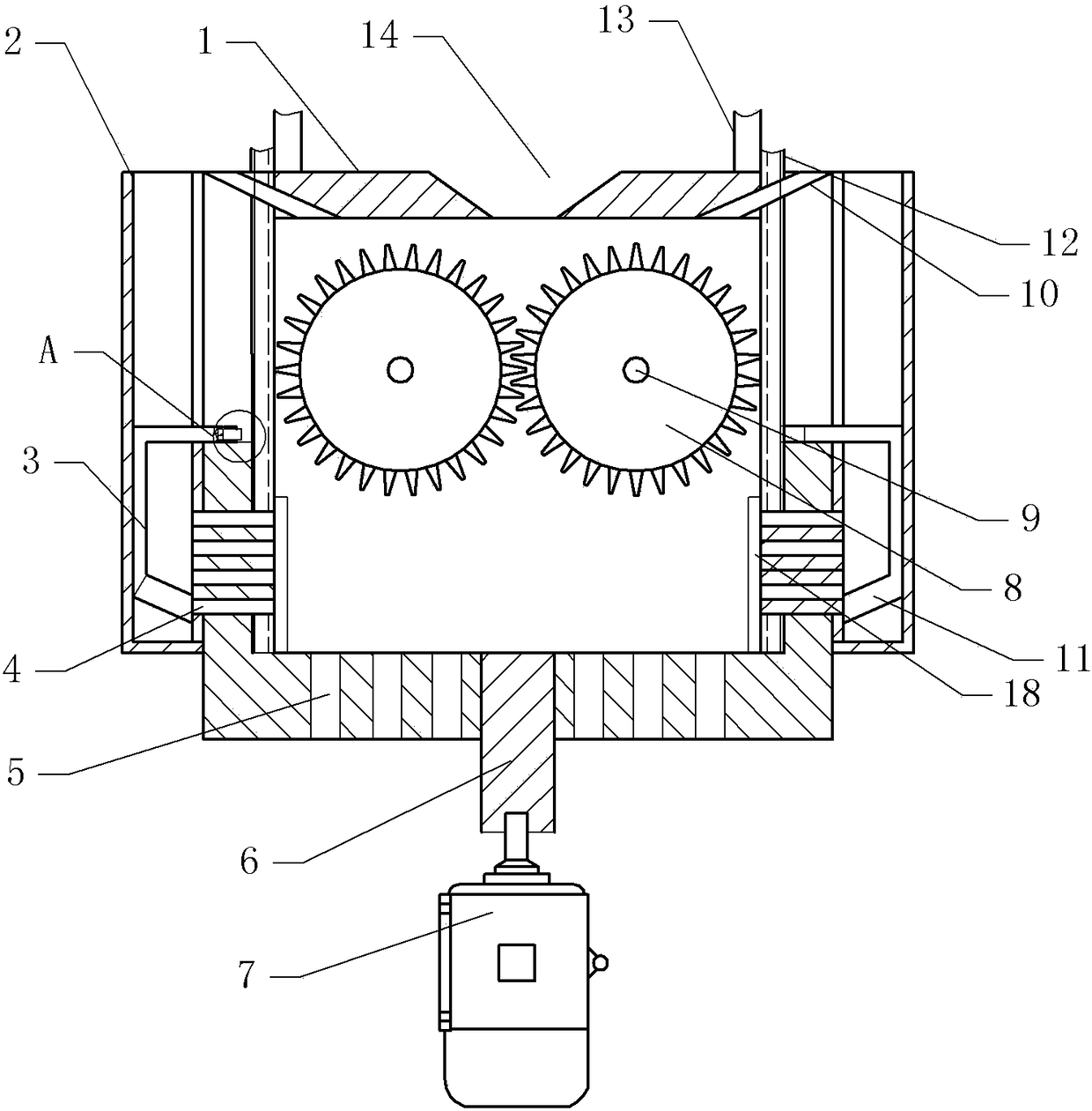

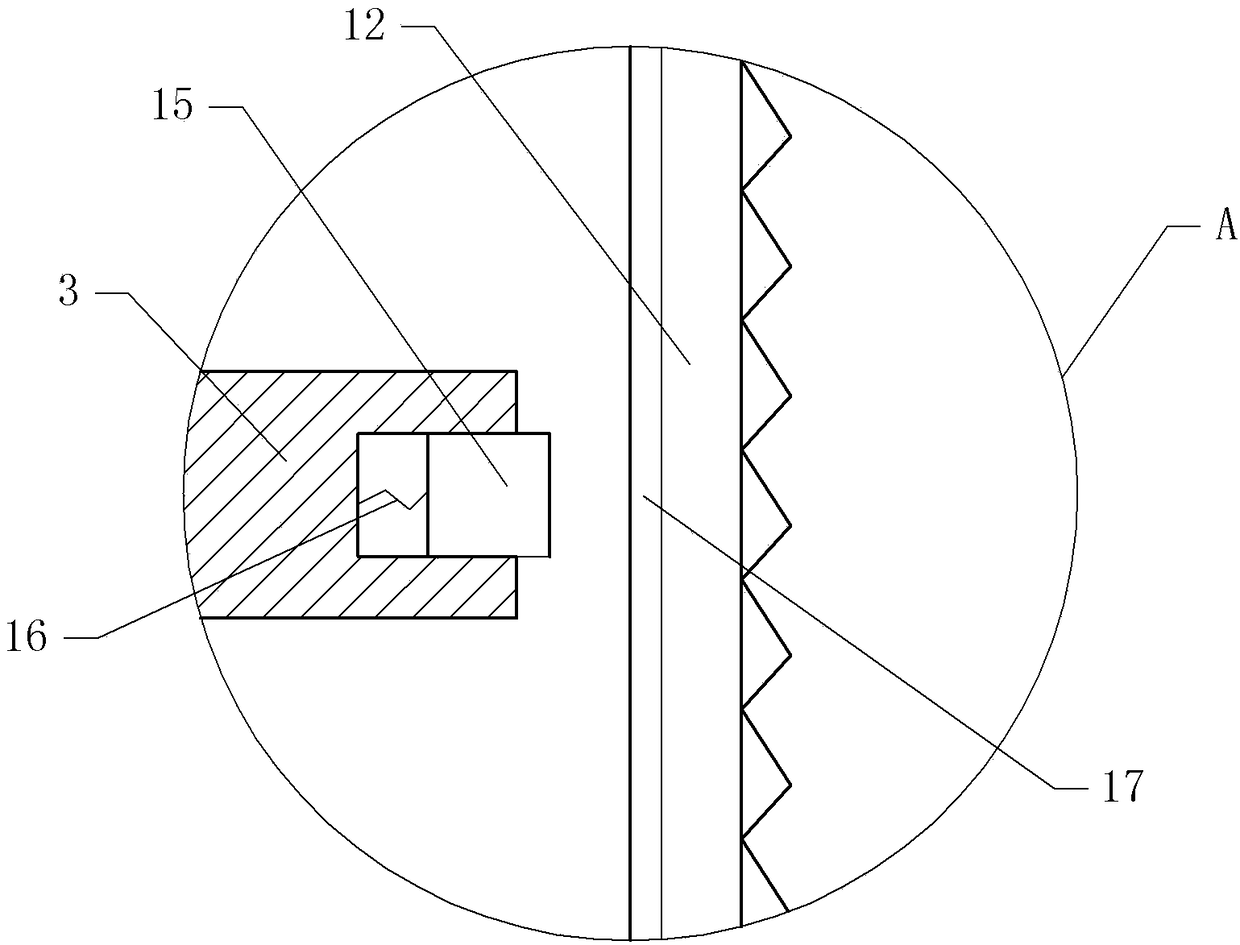

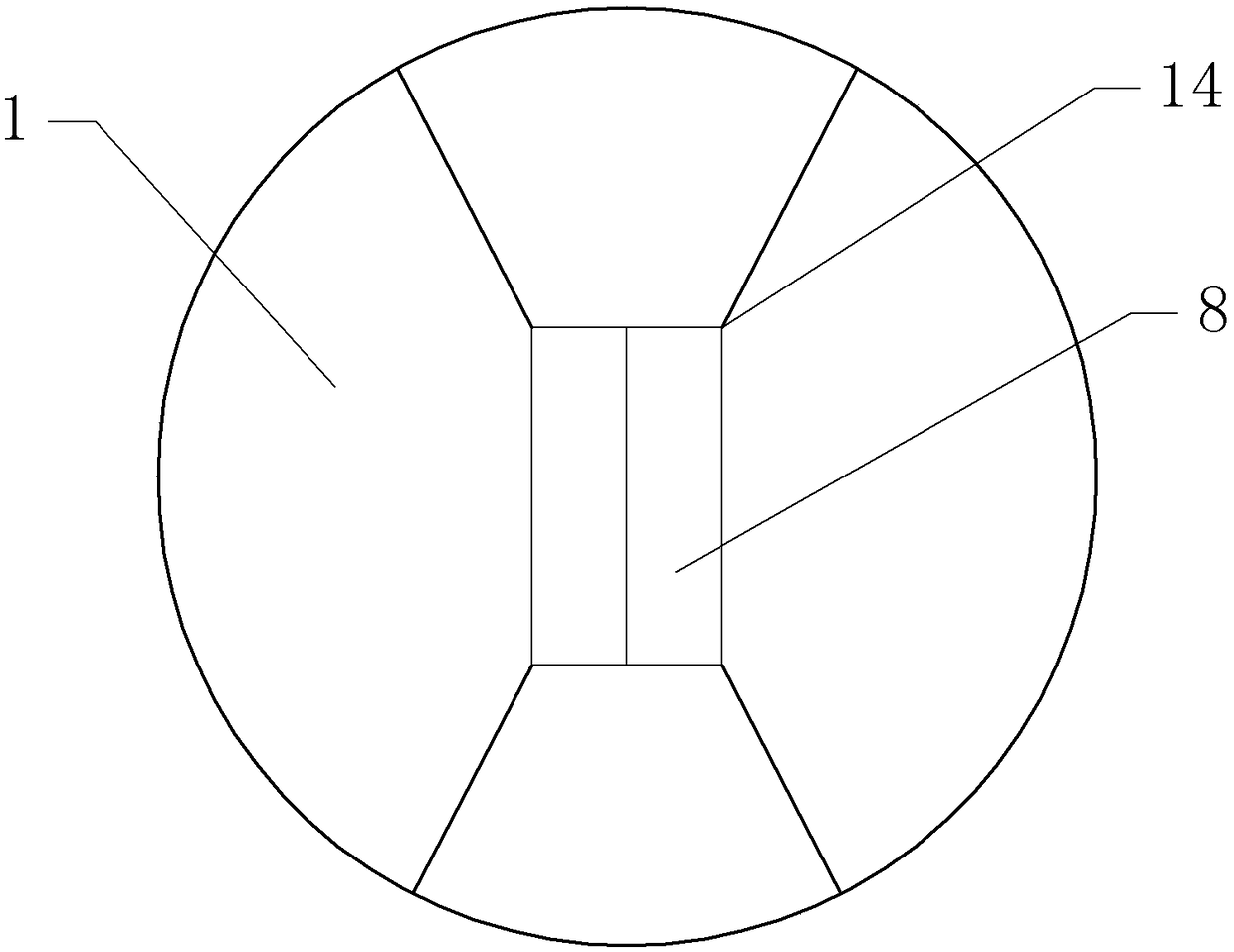

[0026] as attached figure 1 , attached figure 2 And attached image 3 As shown, a kind of ultra-fine plastic pulverizer, comprises frame, first bucket 1 and the second bucket 2 that is connected with frame rotation, and second bucket 2 is set on the outside of first bucket 1 and with first bucket 1 Fixed connection, the opening 14 on the top of the first barrel 1 is inclined towards the bottom of the first barrel 1, and forms a flared shape, so that the upper part of the opening 14 of the first barrel 1 is larger and the lower part is smaller, the upper part of the opening 14 is large to facilitate discharging, and the lower part is small It can reduce powder run-out.

[0027] Two grinding groups are arranged in the first bucket 1, and the grinding group includes a first motor 9 and a gear 8 fixed on the output shaft of the first motor 9, and the gears 8 of the two grinding groups mesh with each other. The side wall of the first barrel 1 is vertically slidably connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com