Preparation method for preparing tin bisulfide catalyst of hydrogen for fuel cell

A tin disulfide, fuel cell technology, used in physical/chemical process catalysts, chemical instruments and methods, electrodes, etc., can solve problems such as affecting electrochemical performance, and achieve high efficiency utilization, improve catalytic activity, and improve dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

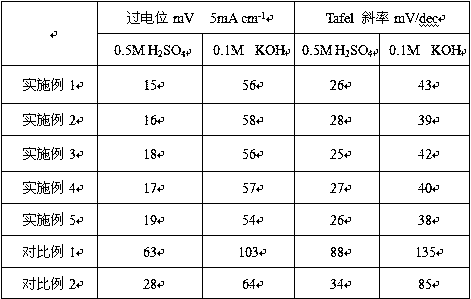

Embodiment 1

[0030](1) The pore diameter is 20nm, and the specific surface area of the catalyst is 500m 2 The cross-linked polymer solid material of amino-modified porous silicone polysiloxane, silicone resin and silicone rubber per gram is placed in the CVD reaction chamber, the modified porous silicone solid material is heated to 480 ° C, and the CVD chamber pumps Vacuum to 0.1Pa, the CVD chamber is kept evacuated for 5 hours, argon is passed for 5 hours, oxygen is discharged, the gas concentration is controlled to be less than 0.001ppm, metal tin is heated to 290°C, thiourea is heated to 200°C, and the heating rate is controlled At 15°C / min, metal tin and thiourea were evaporated, the evaporation rate of thiourea was controlled at 1 mg / h, argon gas was introduced, and the flow rate of argon gas was controlled at 2 sccm. After chemical vapor deposition for 6 hours and 1 hour of heat preservation, the loaded particles with a diameter of 80nm tin disulfide silicone composite material;

...

Embodiment 2

[0035] (1) The pore diameter is 80nm, and the specific surface area of the catalyst is 900m 2 The cross-linked polymer solid material of polyether modified porous silicone polysiloxane, silicone resin and silicone rubber per gram is placed in the CVD reaction chamber, and the modified porous silicone solid material is heated to 500 °C, and the CVD chamber Vacuumize to 10Pa, keep vacuuming the CVD chamber for 3 hours, pass argon gas for 8 hours, discharge oxygen, control the gas concentration to be less than 0.001ppm, heat metal tin to 250°C, heat thiourea to 190°C, and control the heating rate At 7°C / min, metal tin and thiourea were evaporated, the evaporation rate of thiourea was controlled at 20 mg / h, and argon gas was introduced, and the flow rate of argon gas was controlled at 50 sccm. After chemical vapor deposition for 6 hours and 1 hour of heat preservation, the loaded particle size was obtained. 20nm tin disulfide silicone composite material;

[0036] (2) Immerse th...

Embodiment 3

[0040] (1) The pore size is 100nm, and the specific surface area of the catalyst is 300m 2 The cross-linked polymer solid material of phenol-based modified porous organosilicon polysiloxane, silicone resin and silicone rubber per g is placed in the CVD reaction chamber, and the modified porous organosilicon solid material is heated to 490 ° C, and the CVD chamber Evacuate to 0.1-10Pa, keep the CVD chamber evacuated for 3.5 hours, pass argon gas for 7 hours, discharge oxygen, control the gas concentration to be less than 0.001ppm, heat metal tin to 430°C, heat thiourea to 200°C, and heat up The speed is controlled at 7°C / min, metal tin and thiourea are evaporated, the evaporation rate of thiourea is controlled at 25 mg / h, argon gas is introduced, and the flow rate of argon gas is controlled at 2 sccm. After chemical vapor deposition for 6 hours and 1 hour of heat preservation, the loaded particles are obtained. Organosilicon composite material of tin disulfide with a diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com