Mesoporous carbon material loading zero-valent iron, preparation method and application thereof

A mesoporous carbon and zero-valent iron technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problem that the preparation method has not yet been reported, and achieve the chemical structure and performance of the product. Stable, high load rate, small aperture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

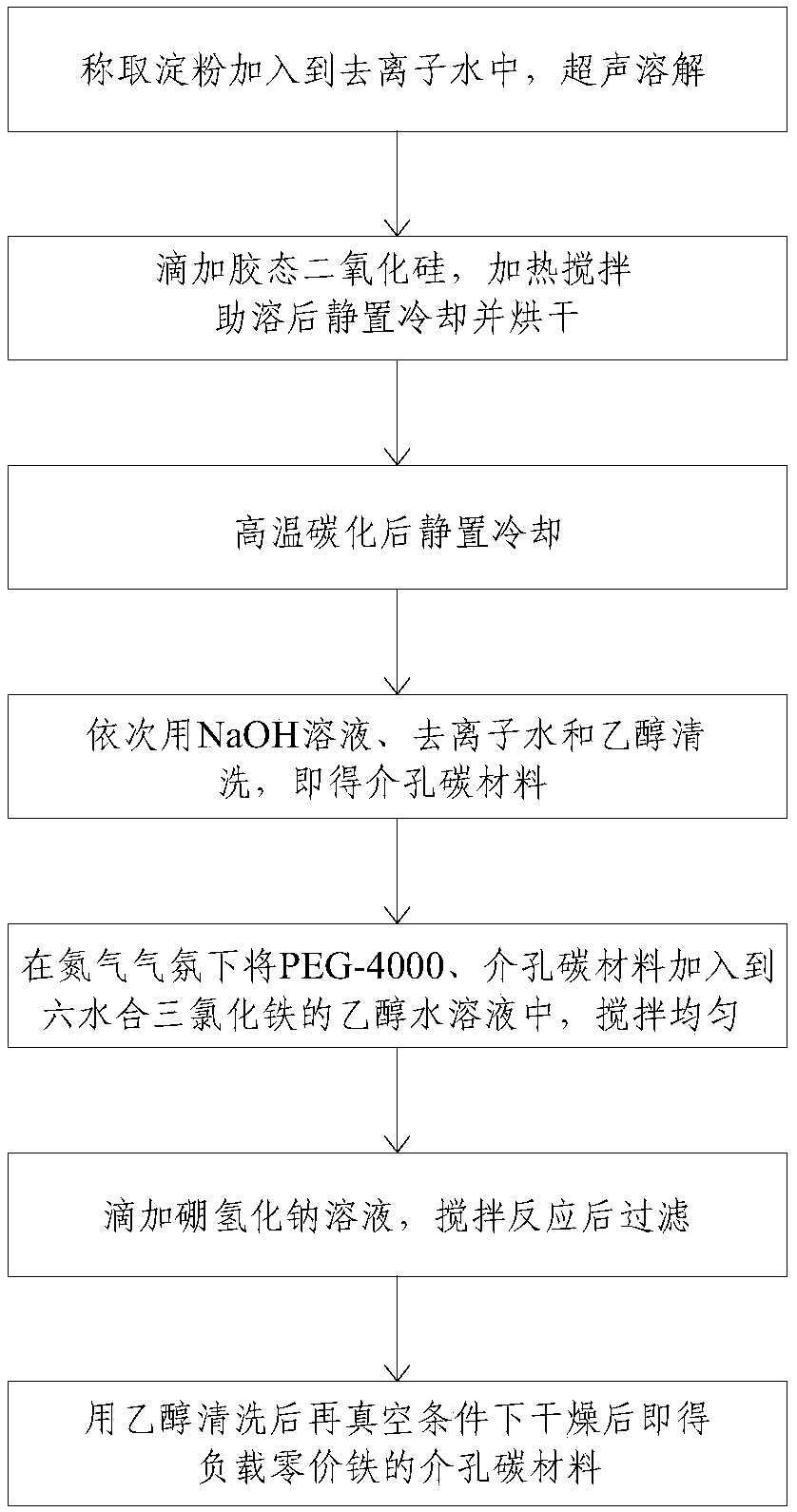

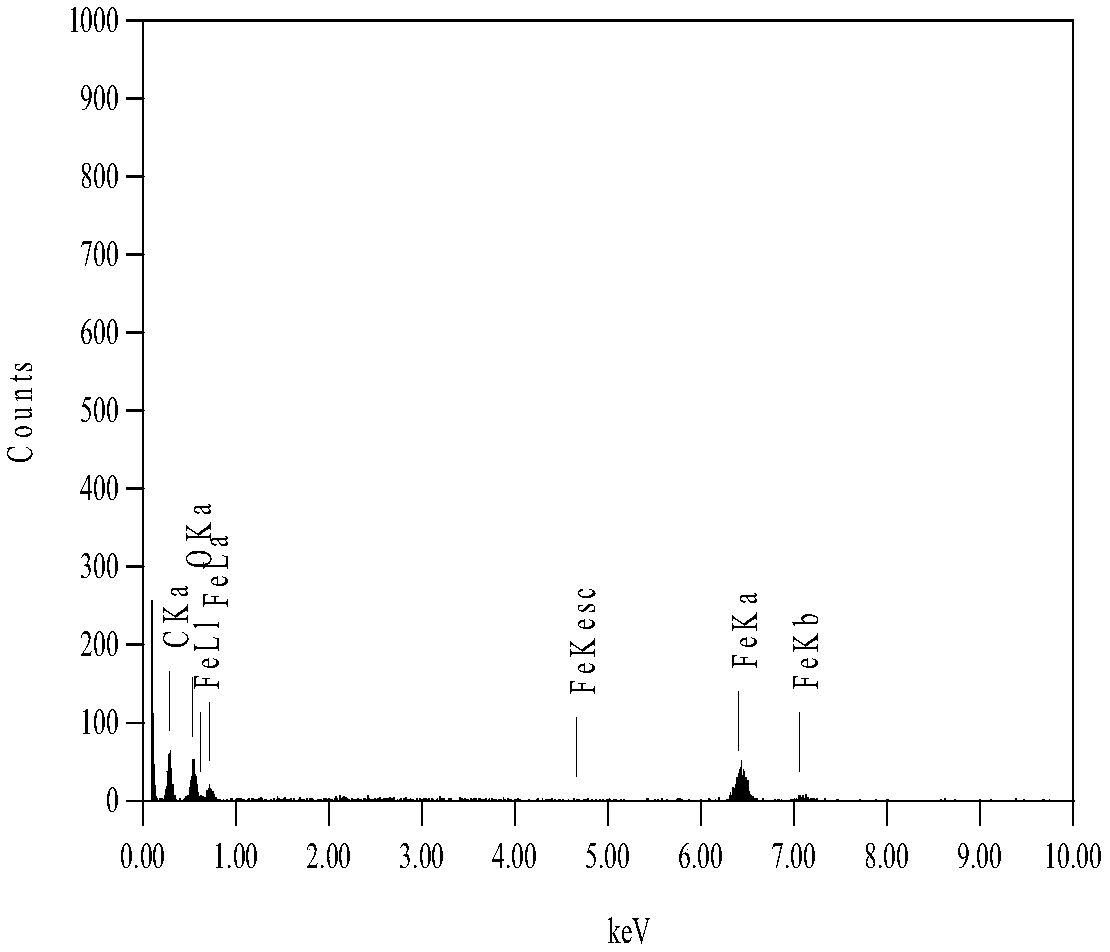

[0030] The embodiment of the present invention provides a method for preparing a mesoporous carbon material loaded with zero-valent iron, such as figure 1 As shown, the specific steps are as follows:

[0031] S1. Weigh 15g of starch and dissolve it in 50mL of deionized water, sonicate for 30min, then heat and stir the starch aqueous solution in a water bath at 80°C for 20min, and then 20g of colloidal dioxide containing 50wt% silica at a rate of 0.1mL / s Silicon was added, then heated and stirred in an oil bath at 120°C for 20min, allowed to stand and cooled, then dried, carbonized at 500°C for 3h, cooled naturally, washed with 100mL NaOH solution with a concentration of 30wt% in a water bath at 70°C, and then used Wash with deionized water until the pH value is 7. Since ethanol is volatile and more conducive to rapid drying, it is finally washed with ethanol three times and dried at 60°C for 24 hours to obtain a mesoporous carbon material;

[0032] S2. Weigh 0.6g ferric chlor...

Embodiment 2

[0035] The embodiment of the present invention provides a method for preparing a mesoporous carbon material loaded with zero-valent iron, and the specific steps are as follows:

[0036] S1. Weigh 15g of starch and dissolve it in 50mL of deionized water, sonicate for 30min, then heat and stir the starch aqueous solution in a water bath at 80°C for 20min, and then 20g of colloidal dioxide containing 50wt% silica at a rate of 0.1mL / s Silicon was added, then heated and stirred in an oil bath at 120°C for 20 minutes, allowed to stand and cooled, then dried, and carbonized at 300°C, 500°C and 700°C for 3 hours, and cooled naturally with 100mL of 30wt% NaOH solution at 70 Wash in a water bath at ℃, and then wash with deionized water until the pH value is 7. Since ethanol is volatile and more conducive to rapid drying, it is finally washed with ethanol three times and dried at 60°C for 24 hours to obtain a mesoporous carbon material;

Embodiment 3

[0043] The embodiment of the present invention provides a method for preparing a mesoporous carbon material loaded with zero-valent iron, and the specific steps are as follows:

[0044] S1. Weigh 15g of starch and dissolve it in 50mL of deionized water, sonicate for 30min, then heat and stir the starch aqueous solution in a water bath at 80°C for 20min, and then 20g of colloidal dioxide containing 50wt% silica at a rate of 0.1mL / s Silicon was added, then heated and stirred in an oil bath at 120°C for 20 minutes, allowed to stand and cooled, then dried, and carbonized at 300°C, 400°C, 500°C, and 600°C for 3 hours, and cooled naturally with 100mL of 30wt% NaOH solution was washed in a water bath at 70°C, and then washed with deionized water until the pH value was 7. Since ethanol is volatile and more conducive to rapid drying, it was finally washed with ethanol three times and dried at 60°C for 24 hours to obtain mesoporous carbon materials;

[0045] S2. Under nitrogen atmosphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com