Preparation method of hollow fiber composite nano-filtration membrane

A fiber composite, nanofiltration membrane technology, applied in the field of water purification, can solve the problems of complex production process of roll-type nanofiltration membrane, high production cost and use cost, low water production rate, etc., and achieve high water flux and chemical stability. performance, good desalination rate, and the effect of reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

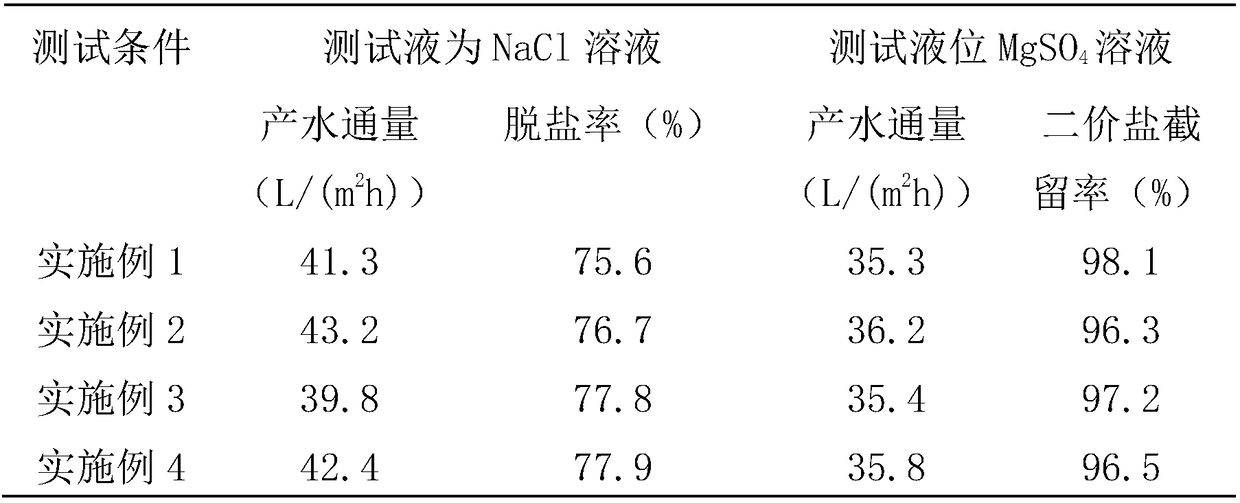

Examples

Embodiment 1

[0021] (1) Mix and stir alumina ceramic powder with an average particle size of 0.3 μm, polyethersulfone, N-methylpyrrolidone, and polyvinylpyrrolidone in a mass ratio of 50%: 7.2%: 42%: 0.8%, and vacuum suction After 12 hours, the air bubbles in the film-forming liquid are removed to form a uniform and stable film-forming raw material;

[0022] (2) According to mass concentration, polyvinylphosphoric acid is 2g / L, potassium hydroxide is 2g / L polyelectrolyte preparation proteolytic alkali solution, with above-mentioned polyelectrolyte alkali solution as external coagulation bath, with water and dimethylformamide The mixed liquid with a mass concentration of dimethylformamide of 70% is used as an internal coagulation bath, and the above-mentioned hollow fiber ultrafiltration membrane spinning membrane forming system is formed by spinning through a hollow spinneret and a double diffusion process.

[0023] (3) After the above-mentioned hollow fiber ultrafiltration membrane struct...

Embodiment 2

[0025] (1) Mix and stir zirconia ceramic powder with an average particle size of 0.3 μm, polyethersulfone, N-methylpyrrolidone, and polyvinylpyrrolidone in a mass ratio of 50%: 7.2%: 42%: 0.8%, and vacuum pump Suction for 18 hours, remove the air bubbles in the film-forming liquid, and form a uniform and stable film-forming raw material;

[0026] (2) According to the mass concentration, polyvinylphosphoric acid is 1g / L, potassium hydroxide is 1g / L polyelectrolyte preparation solution alkali solution, with the above-mentioned polyelectrolyte alkali solution as the external coagulation bath, with water and dimethylformamide The mixed liquid with a mass concentration of dimethylformamide of 60% is used as an internal coagulation bath, and the above-mentioned hollow fiber ultrafiltration membrane spinning membrane forming system is formed by spinning through a hollow spinneret and a double diffusion process.

[0027] (3) After the above-mentioned hollow fiber ultrafiltration membr...

Embodiment 3

[0029] (1) Mix and stir titanium dioxide ceramic powder with an average particle size of 0.5 μm, polyethersulfone, N-methylpyrrolidone, and polyvinylpyrrolidone in a mass ratio of 50%: 7.2%: 42%: 0.8%, and vacuum pump for 18 Hours, remove the air bubbles in the film-forming liquid to form a uniform and stable film-forming raw material;

[0030] (2) According to mass concentration, polyvinylphosphoric acid is 2g / L, potassium hydroxide is 2g / L polyelectrolyte preparation proteolytic alkali solution, with above-mentioned polyelectrolyte alkali solution as external coagulation bath, with water and dimethylformamide The mixed liquid with a mass concentration of dimethylformamide of 70% is used as an internal coagulation bath, and the above-mentioned hollow fiber ultrafiltration membrane spinning membrane forming system is formed by spinning through a hollow spinneret and a double diffusion process.

[0031] (3) After the above-mentioned hollow fiber ultrafiltration membrane structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com