Preparation method for hollow fiber composite nanofiltration membrane

A fiber composite and nanofiltration membrane technology, applied in the field of membrane separation, can solve the problems of narrow working temperature range, poor corrosion resistance, poor mechanical strength, etc., achieve good desalination rate, compensate for easy swelling, and have wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

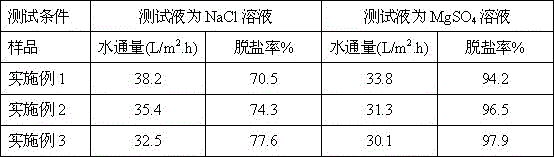

Embodiment 1

[0015] (1) Mix ceramic powder, high molecular polymer, organic solvent and dispersant at a mass ratio of 50%: 7.5%: 42%: 0.5% and stir evenly. After defoaming for 24 hours, pass through a hollow chamber under a driving pressure of 0.1MPa. The fiber spinneret is sprayed out, the flow rate of the core liquid is 40ml / min, the space between the air sections is 10cm, and after drying at room temperature, it is sintered at a high temperature of 1550°C to obtain a hollow fiber ceramic support body.

[0016] (2) Mix and stir sulfonated polyethersulfone, film-forming solvent, and additives at a mass ratio of 10%: 60%: 30% evenly, seal both ends of the hollow fiber ceramic support with raw material tape and immerse vertically in the above-mentioned Stay in the homogeneous solution for 10s, take out the air flow to sweep the surface liquid film layer, repeat three times, and finally place in deionized water to fully remove the solvent, dry in an oven to obtain a hollow fiber composite mem...

Embodiment 2

[0018] (1) Mix ceramic powder, high molecular polymer, organic solvent and dispersant at a mass ratio of 50%: 7.5%: 42%: 0.5% and stir evenly. After defoaming for 24 hours, pass through a hollow chamber under a driving pressure of 0.1MPa. The fiber spinneret is sprayed out, the flow rate of the core liquid is 40ml / min, the space between the air sections is 10cm, and after drying at room temperature, it is sintered at a high temperature of 1550°C to obtain a hollow fiber ceramic support body.

[0019] (2) Mix and stir sulfonated polyethersulfone, film-forming solvent, and additives at a mass ratio of 12%:55%:33% evenly, seal both ends of the hollow fiber ceramic support with raw material tape, and immerse vertically in the above-mentioned Stay in the homogeneous solution for 10s, take out the air flow to sweep the surface liquid film layer, repeat three times, and finally place in deionized water to fully remove the solvent, dry in an oven to obtain a hollow fiber composite memb...

Embodiment 3

[0021] (1) Mix ceramic powder, high molecular polymer, organic solvent and dispersant at a mass ratio of 50%: 7.5%: 42%: 0.5% and stir evenly. After defoaming for 24 hours, pass through a hollow chamber under a driving pressure of 0.1MPa. The fiber spinneret is sprayed out, the flow rate of the core liquid is 40ml / min, the space between the air sections is 10cm, and after drying at room temperature, it is sintered at a high temperature of 1550°C to obtain a hollow fiber ceramic support body.

[0022] (2) Mix and stir sulfonated polyethersulfone, film-forming solvent, and additives at a mass ratio of 14%:52%:34% evenly, seal both ends of the hollow fiber ceramic support with raw material tape, and then immerse vertically in the above-mentioned Stay in the homogeneous solution for 10s, take out the air flow to sweep the surface liquid film layer, repeat three times, and finally place in deionized water to fully remove the solvent, dry in an oven to obtain a hollow fiber composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com