Dura mater biopatch and preparation method thereof

A biological patch and dura mater technology, applied in tissue regeneration, medical science, prosthesis, etc., can solve the problems of poor decellularization and degreasing, tissue toxicity, and high content of immunogenic substances, and prevent cerebrospinal fluid leakage. Leakage, low immune rejection, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

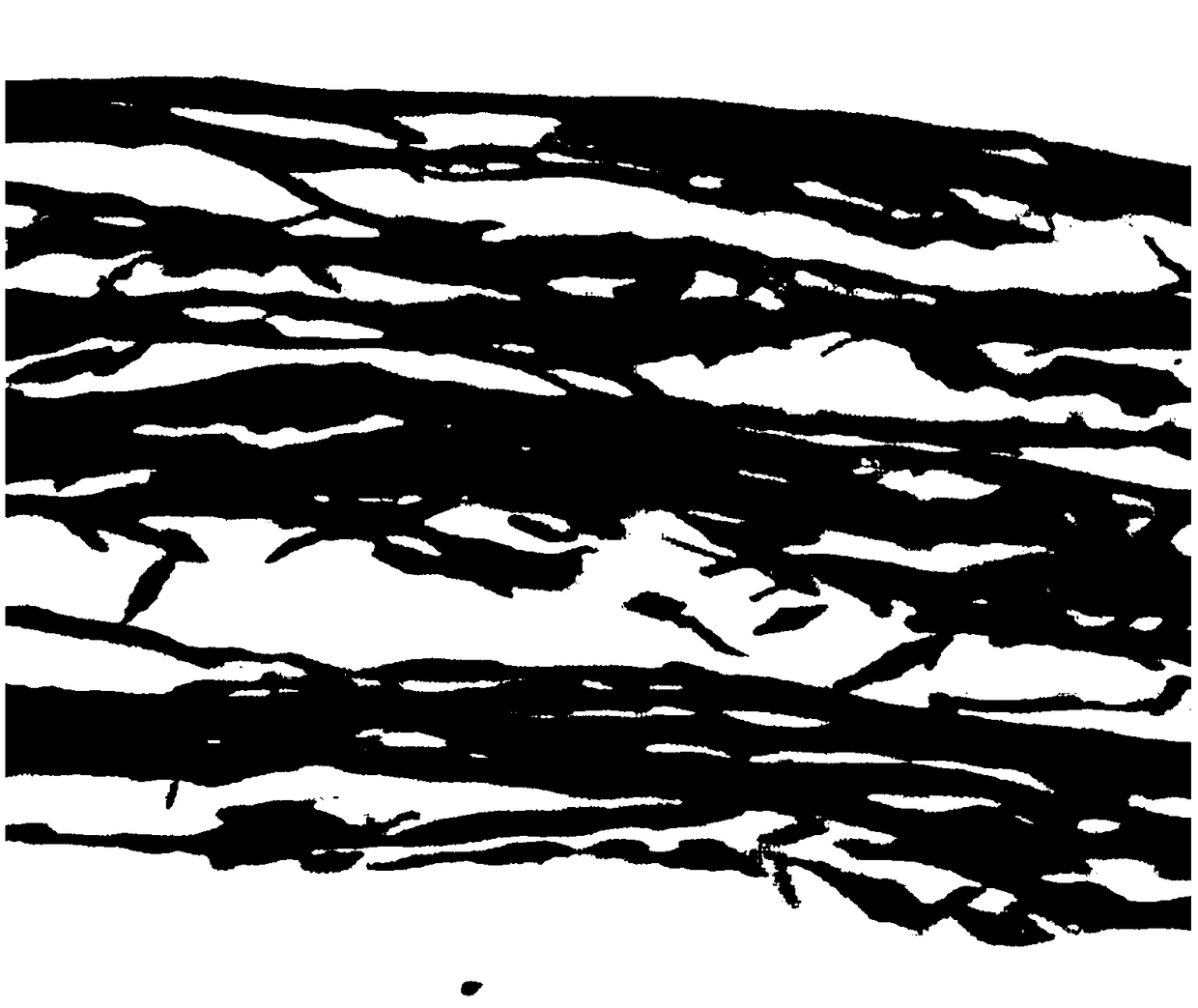

Image

Examples

Embodiment 1

[0051] (1) Pretreatment

[0052] Freshly slaughtered porcine small intestine tissues were cleaned, soaked in 0.5% acetic acid solution for 30 minutes, the ratio of porcine small intestine to acetic acid solution was 1:5, and the mucosal layer, muscular layer and serosa layer of porcine small intestine and jejunum were removed by physical scraping , Lymph nodes, the submucosa was separated, cut into pieces, and washed 3 times with purified water.

[0053] (2) Disinfection

[0054] Use a mixed aqueous solution containing 1.0% peracetic acid and 15% ethanol, the ratio of the SIS material to the mixed aqueous solution is 1:10, and immerse at room temperature for 100 minutes under ultrasonic conditions for disinfection. Afterwards, it was ultrasonically washed 3 times with purified water.

[0055] (3) Degreasing

[0056] Use ethanol with a concentration of 95%, the ratio of SIS material to ethanol is 1:10, and soak at room temperature for 2 hours under ultrasonic conditions. Af...

Embodiment 2

[0064] Example 2: The samples prepared in Example 1 were subjected to physical property testing, chemical property testing, histological testing, growth factor testing, biological property testing and animal tests.

[0065] 1. Physical performance testing

[0066] 1) Water resistance

[0067] Method: Refer to the method of "YY / T 0471.3-2004 Test Method for Contact Wound Dressing Part 3: Water Resistance" for testing.

[0068] The result: water-repelling properties.

[0069] 2) Suture strength

[0070] Method: Use 3-0 non-absorbable suture to suture at the center of both sides of the patch at a distance of 2mm from the edge, fix the other end of the suture and the other end of the sample on the two ends of the tension meter respectively, and stretch it at a speed of 20mm / min. Record the maximum force until the suture is torn. Three batches of samples were tested according to the above method.

[0071] Results: The suture strength is in the range of 3N-5N.

[0072] 3) Tens...

Embodiment 3

[0111] (1) Pretreatment

[0112] Freshly slaughtered porcine small intestine tissues were cleaned, soaked in 0.5% acetic acid solution for 30 minutes, the ratio of porcine small intestine to acetic acid solution was 1:5, and the mucosal layer, muscular layer and serosa layer of porcine small intestine and jejunum were removed by physical scraping , Lymph nodes, the submucosa was separated, cut into pieces, and washed 3 times with purified water.

[0113] (2) Disinfection

[0114] Use a mixed aqueous solution containing 1.0% peracetic acid and 15% ethanol, the ratio of the SIS material to the mixed aqueous solution is 1:10, and immerse at room temperature for 100 minutes under ultrasonic conditions for disinfection. Afterwards, it was ultrasonically washed 3 times with purified water.

[0115] (3) Freeze-drying and sterilization

[0116] Four layers of SIS materials were superimposed, fixed on the mold, freeze-dried, cut into 4cm×7cm size, packed in PET bags, and finally ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| suture strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com