Double-layer induction heating vessel

A technology of induction heating and induction heating, applied in the direction of drinking utensils, etc., can solve the problems of energy waste, low heating efficiency, heat dissipation around the environment, etc., to ensure the temperature of the tea, improve the heating effect, and prevent the effect of scalding the human body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

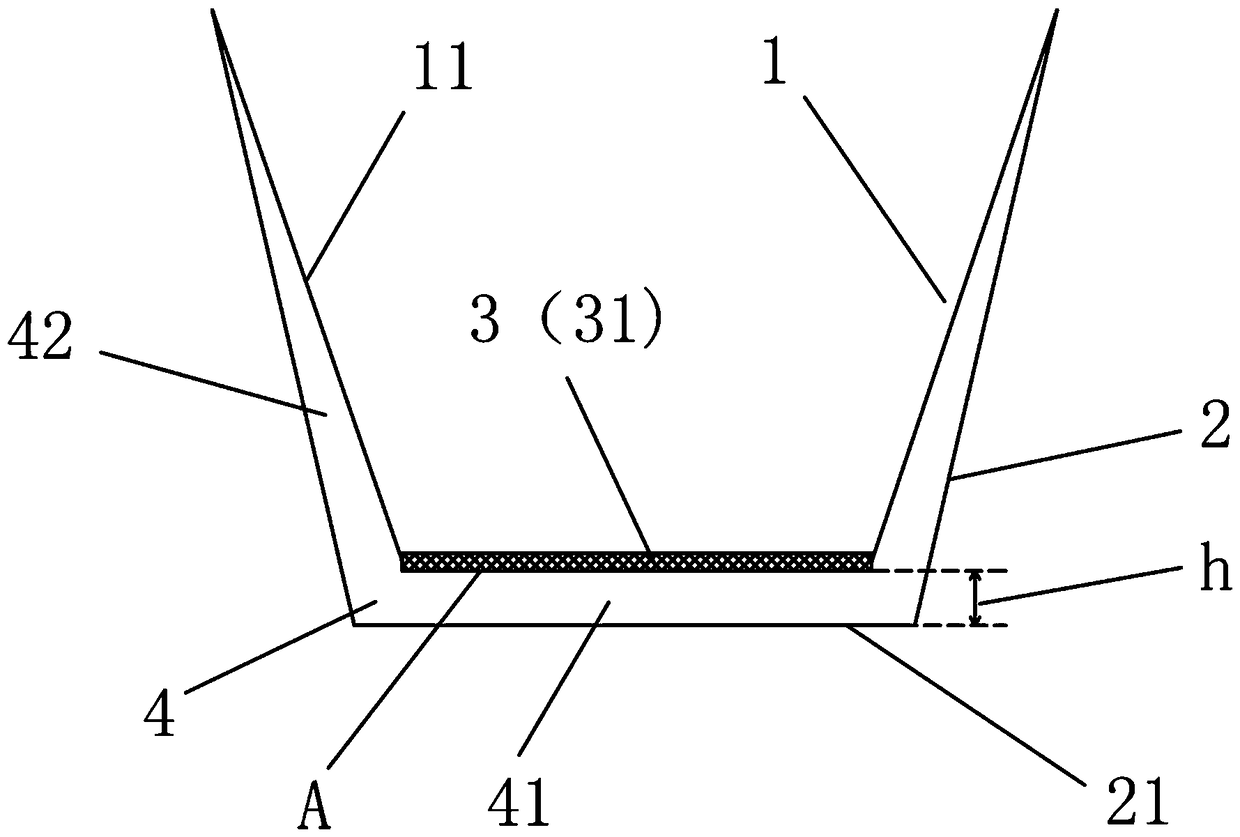

[0026] Embodiment one: if figure 1 As shown, a double-layer induction heating vessel, this embodiment takes a teacup as an example: a teacup, including an inner layer 1 and an outer layer 2, the outer layer 2 is made of glass material, and the outer layer 2 is provided with an outer layer The bottom layer 21 is sealed, and a vacuum chamber 4 is provided between the outer layer 2 and the inner layer 1, wherein the inner layer 1 includes a glass side wall 11, and an induction heating bottom wall 3 arranged at the bottom opening of the glass side wall 11, namely: The glass side wall 11 and the induction heating bottom wall 3 enclose the inner layer 1, the bottom end 21 of the outer layer 2 is lower than the induction heating bottom wall 3 of the inner layer 1, and the bottom end 21 of the outer layer 2 The vertical height difference h between the bottom surface A of the induction heating bottom wall 3 of the inner layer 1 is between 0.1mm-50mm; in this embodiment, the induction h...

Embodiment 2

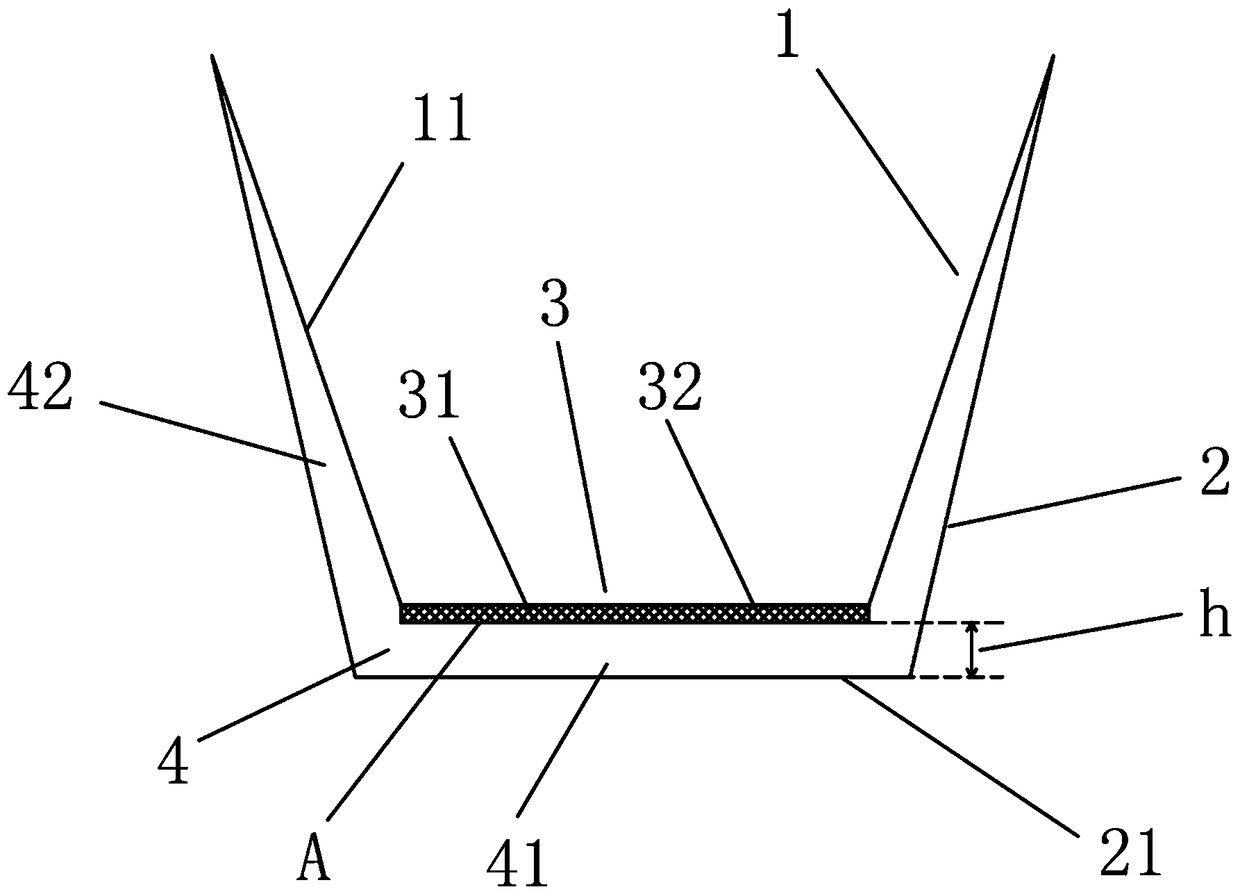

[0029] Embodiment two: if figure 2 As shown, this embodiment is also a double-layer induction heating vessel, and its structure is similar to that of the above-mentioned embodiment 1, the difference is that: the inner induction heating bottom wall 3 includes a closed bottom layer 32 and a metal heating layer 31, The airtight bottom layer 32 is a non-metal heat-conducting material layer, including a glass, pottery or other non-metal heat-conducting material. The metal heating layer 31 is fixed on the lower surface of the airtight bottom layer 32. The metal coating on the lower surface of the bottom layer 32.

[0030] Working principle: this embodiment is similar to the working principle of embodiment 1, the difference is: after the metal heating layer 33 generates heat, the heat is transmitted to the inner layer 1 through the airtight bottom layer 32, which can also achieve the effect of this patent.

Embodiment 3

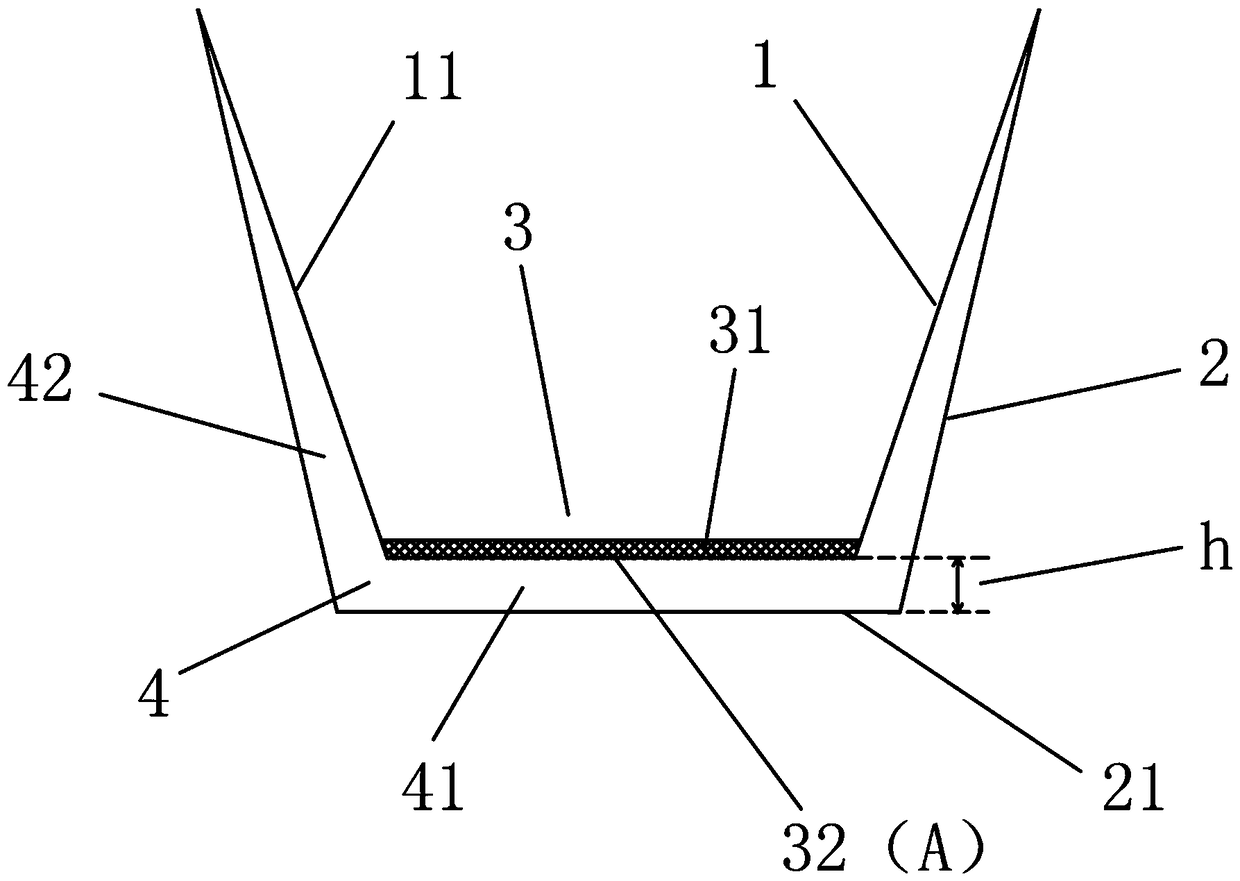

[0031] Embodiment three: as image 3 As shown, this embodiment is also a double-layer induction heating vessel, and its structure is similar to the above-mentioned embodiment two, the difference is: the metal heating layer 31 is fixed on the upper surface of the airtight bottom layer 32, and the metal heating layer here is The layer 31 may be a metal coating on the upper surface of the airtight bottom layer 32 , and the airtight bottom layer 32 is the bottommost surface A of the bottom wall 3 for induction heating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com