Driving device for cycle motion of tree digging cutter

A driving device and cutting tool technology, applied in forestry, application, agriculture, etc., can solve the problems of high labor intensity, high cost, and difficulty in ensuring the quality of soil balls, and achieve the effect of convenient operation and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

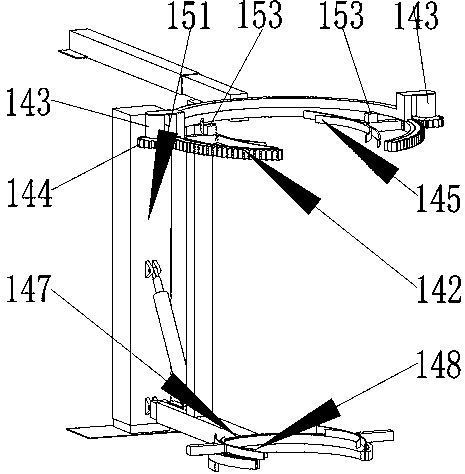

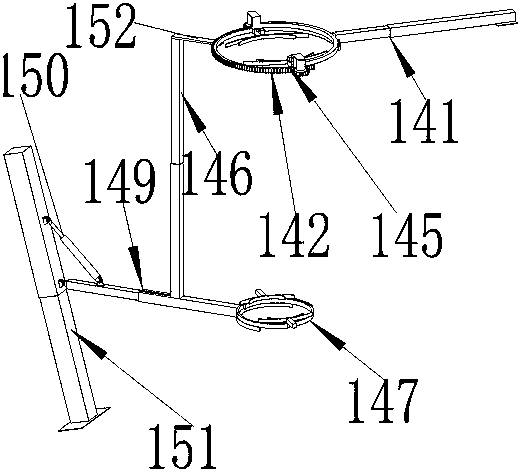

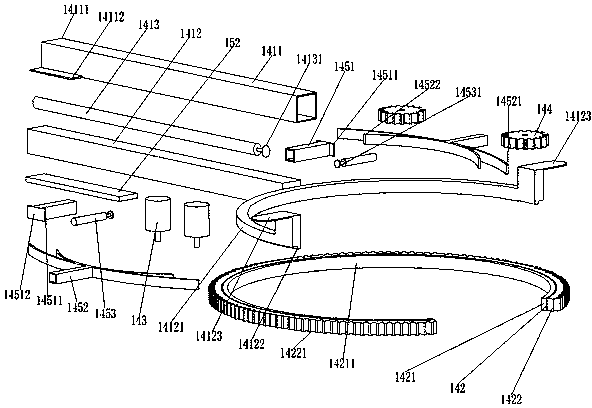

[0031] see figure 1 , figure 2 and Figure 5 As shown, the present invention is composed of a first telescopic assembly 141, a first C-shaped slewing bearing assembly 142, two low-speed high-torque hydraulic motors 143, two first gears 144, two first clamping assemblies 145, a second telescopic Assembly 146, second C-shaped slewing bearing assembly 147, two second clamping assemblies 148, third telescopic assembly 149, luffing hydraulic cylinder 150, fourth telescopic assembly 151, plate cantilever beam 152 and two laser displacement sensors 153 Composition, luffing hydraulic cylinder 150 cylinder body is provided with double clevis 1501, piston rod is provided with single clevis 1502;

[0032] see image 3 As shown, the first telescopic assembly 141 is composed of a first square cylindrical fixed arm 1411, a first square cylindrical telescopic arm 1412 and a first hydraulic cylinder 1413, and the first square cylindrical fixed arm 1411 is provided with a closed end 14111...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com