Efficiency natural gas directional flow heating system

A directional flow, heating system technology, applied in pipeline systems, pipeline heating/cooling, heat exchange equipment, etc., can solve the problems of low thermal efficiency of LNG recuperators, and achieve the effect of fast heating speed, high thermal efficiency and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

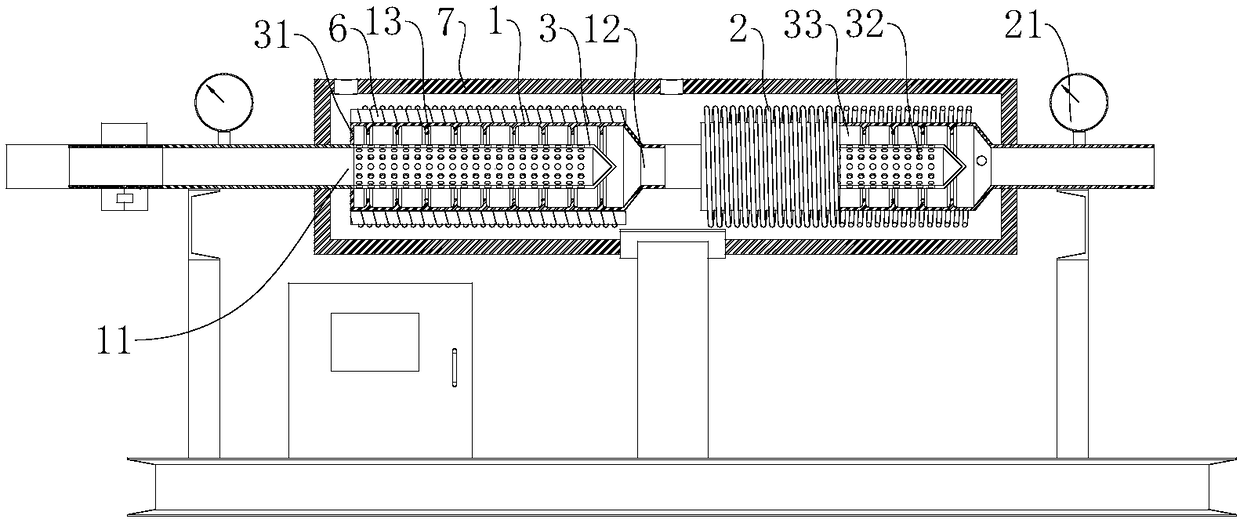

[0032] Example 1: A high-efficiency natural gas directional flow heating system, with a structure such as figure 1 As shown, it includes a regulating module and an induction coil 2 wound on the outside of the heat exchange tube 1. The heat exchange tube 1 includes a natural gas inlet 11 and a natural gas outlet 12. The induction coil 2 heats the heat exchange tube 1. When the natural gas passes through the heat exchange tube 1 , heated by heat exchange tube 1, combined with Figure 4 Look, multiple sets of fins 13 are arranged on the inner wall of the heat exchange tube 1, which can increase the contact area between the natural gas and the high-temperature heat exchange tube 1, thereby improving the heating efficiency of the natural gas. In some cases, multiple sub-stage heat exchange tubes can be combined to form a multi-stage heat exchange, and the induction coil 2 on each heat exchange tube 1 can be independently controlled, so that the adjustment module can regulate the wo...

Embodiment 2

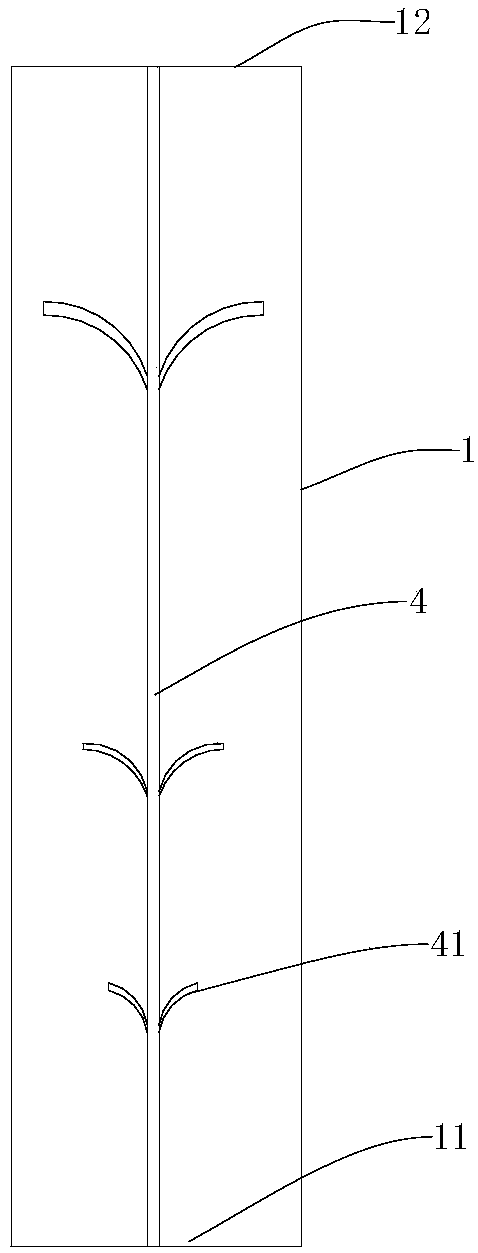

[0039] Embodiment 2: A high-efficiency natural gas directional flow heating system, which differs from Embodiment 1 in that, as image 3 with 4 As shown, the directional flow device includes a fixed rod 4 arranged inside the heat exchange tube 1, and a plurality of flow guides are arranged on the fixed rod 4, and the flow guides include a plurality of arc-shaped guide fins 41, and the arc-shaped guide fins 41 One end is fixedly connected with the fixed rod 4, and the other end extends toward the direction of the heat exchange tube 1. The end of the arc-shaped deflector 41 away from the fixed rod 4 is set close to the natural gas outlet 12, and the outer side of the arc-shaped deflector 41 is close to the fixed rod 4. set up.

[0040] The arc-shaped deflectors 41 in adjacent deflectors are staggered, and the length of the arc-shaped deflectors 41 in the deflectors gradually increases from one end close to the natural gas inlet 11 to the other end. The distance gradually incre...

Embodiment 3

[0043] Embodiment 3: A high-efficiency natural gas directional flow heating system, which differs from Embodiment 1 in that, as Figure 5 As shown, the heat exchange tube 1 includes a first heat exchange tube 8 located inside and a second heat exchange tube 9 located outside, the induction coil 2 is wound on the first heat exchange tube 8, and is located between the first heat exchange tube 8 and the Between the second heat exchange tubes 9, a first channel 81 for natural gas is formed inside the first heat exchange tube 8, and a second channel 91 for natural gas is formed between the tube wall of the second heat exchange tube 9, the first channel 81 for natural gas and the second channel 81 for natural gas The ends of the two channels 91 away from the natural gas inlet 11 communicate with each other, and the end of the second heat exchange tube 9 close to the natural gas inlet 11 is provided with a natural gas outlet 12 communicating with the second natural gas channel 91 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com