Efficient high-temperature curing technology of silicon carbide seed crystals

A technology of high-temperature solidification and silicon carbide, which is applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems affecting the quality of crystal growth and general fixation effect, and achieve good fixation effect, good fixation and complete graphitization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

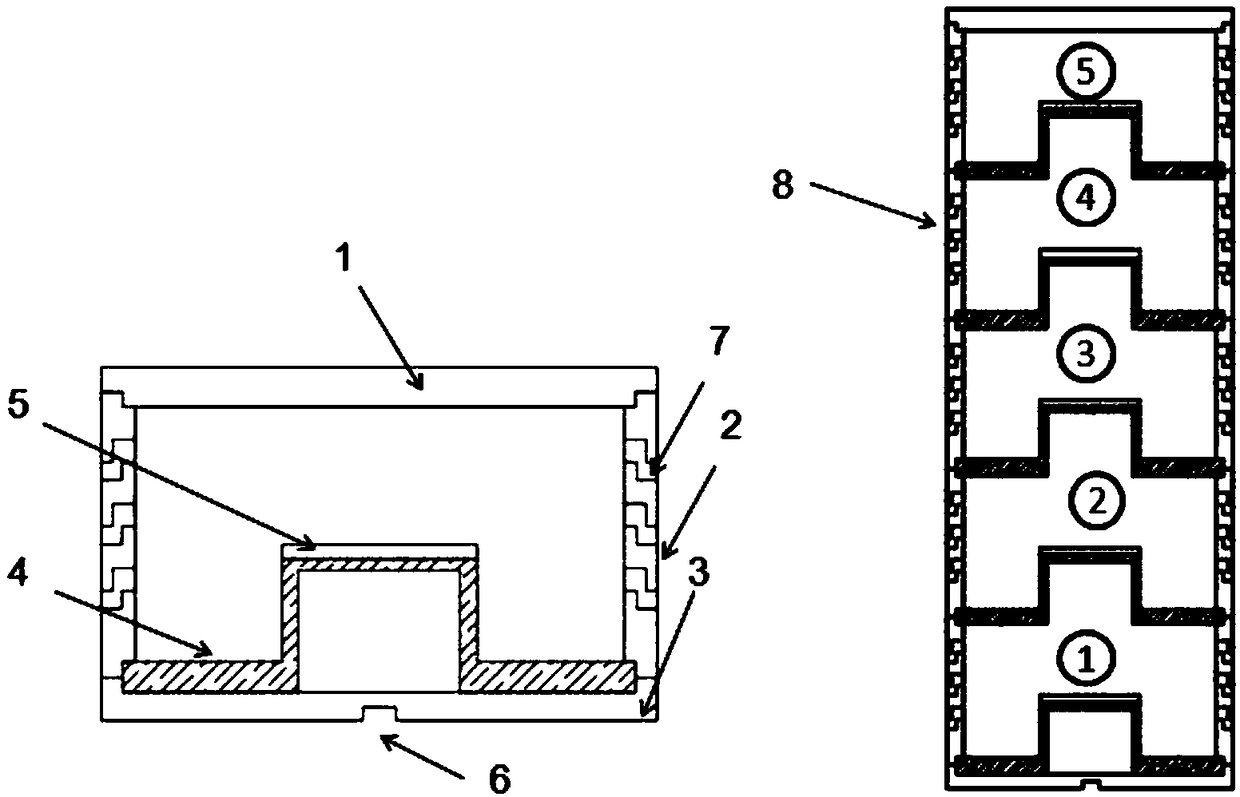

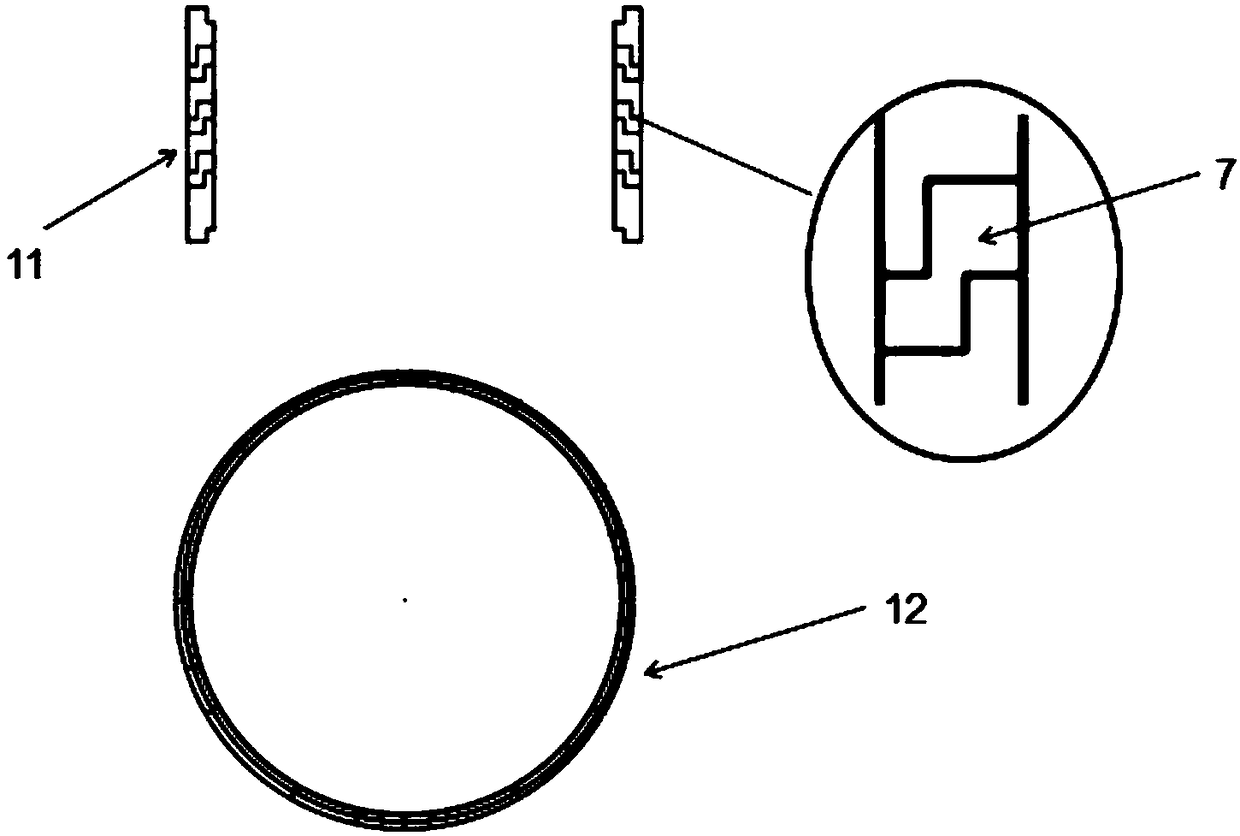

[0042] A process for high-efficiency high-temperature solidification of silicon carbide seed crystals, using a crucible fixture with a cover, a crucible cover, a crucible with a thickness of 10mm, a chassis, a temperature measurement hole on the chassis with a diameter of 5mm, and a vent hole for high-temperature solidification of silicon carbide seed crystals ; Every two adjacent air holes with a diameter of 10mm form an inverted Z shape, the central axes of the two holes are respectively inclined at 5° from the horizontal line, and the central axes of the inner and outer holes are 1 / 4 of the air hole diameter apart, and they meet and overlap at the center of the crucible wall The intersection and conduction at the intersection, wherein the inner hole is at a high position; the crucible fixture is made of graphite material; the temperature measurement hole of the chassis is measured and controlled by an infrared pyrometer; the following steps are included:

[0043] Step S1, pa...

Embodiment 2

[0052] A process for high-efficiency high-temperature solidification of silicon carbide seed crystals, using a crucible fixture with a cover, a crucible cover, a crucible with a thickness of 30 mm, a chassis, a temperature measurement hole on the chassis with a diameter of 20 mm, and a vent hole for high-temperature solidification of silicon carbide seed crystals ; Each two adjacent air holes with a diameter of 30mm form an inverted Z-shape, the central axes of the two holes are respectively inclined at 15° from the horizontal line, and the central axes of the inner and outer holes are 1 / 4 of the air hole diameter apart, and they meet and overlap at the center of the crucible wall The intersection and conduction at the intersection, wherein the inner hole is at a high position; the crucible fixture is made of graphite material; the temperature measurement hole of the chassis is measured and controlled by an infrared pyrometer; the following steps are included:

[0053] Step S1,...

Embodiment 3

[0062] A process for high-efficiency high-temperature solidification of silicon carbide seed crystals, using a crucible fixture with a lid, a crucible cover, a crucible with a thickness of 20mm, a chassis, a chassis temperature measuring hole with a diameter of 12.5mm, and a vent hole for high temperature silicon carbide seed crystals Solidification; every two adjacent air holes with a diameter of 20mm form an inverted Z-shape, the central axes of the two holes are respectively inclined at 10° from the horizontal line, and the central axes of the inner and outer holes are 1 / 4 of the air hole diameter apart, and meet at the center of the crucible wall The overlaps meet and conduct, and the inner hole is at a high position; the crucible fixture is made of graphite material; the temperature measurement hole of the chassis is measured and controlled by an infrared pyrometer; the following steps are included:

[0063] Step S1, paste the silicon carbide seed crystal on the crucible c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com