Water-based antiwax remover and preparation method thereof

A wax-removing, water-based technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems that the preparation method needs to be improved, and achieve a wide range of applicable temperature, strong ability to adapt to working conditions, and energy saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

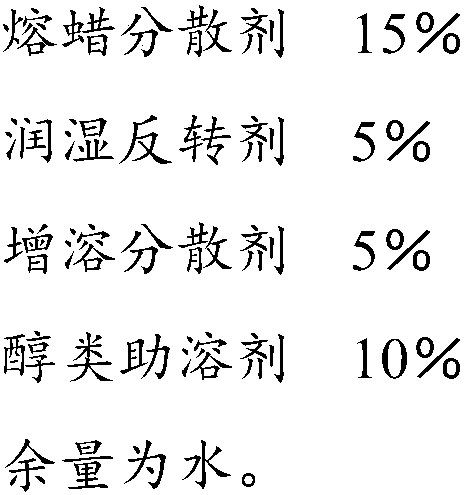

[0035] A water-based wax remover, comprising the following raw material components in percentage by weight:

[0036]

[0037] Among them, the melting wax dispersant is a 3:1 mixture of methyl stearate polyoxyethylene ether and polyethylene glycol dioleate, and the wetting reversal agent is polyoxyethylene alkyl alcohol ether sulfate salt, solubilizing and dispersing The agent is coconut oil fatty acid diethanolamide, and the alcohol co-solvent is a mixture of methanol, ethanol, and n-butanol according to the ratio of 3:2:1.

[0038] The preparation method of the above water-based wax remover and anti-wax agent: add wax-melting dispersant, wetting reversal agent and solubilizing dispersant to the reaction kettle and mix evenly, then add alcohol co-solvent and stir for half an hour, add water and stir until uniform.

Embodiment 2

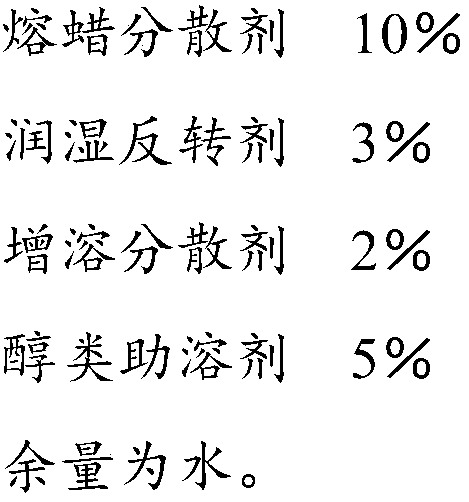

[0040] A water-based wax remover, comprising the following raw material components in percentage by weight:

[0041]

[0042] Among them, the melting wax dispersant is a 3:1 mixture of methyl stearate polyoxyethylene ether and fatty acid methyl ester ethoxylate sulfonate, the wetting reversal agent is polyoxyethylene alkylphenol ether, and the solubilizing and dispersing agent It is a 1:1:1 mixture of polyethylene glycol dioleate, fatty alcohol polyoxyethylene ether, and nonylphenol polyoxyethylene ether. The alcohol co-solvent is methanol, ethanol, and n-butanol according to the ratio of 3:2:1 mixture.

[0043] The preparation method of the above water-based wax remover and anti-wax agent: add alcohol co-solvent, wax-melting dispersant, wetting reversal agent and stir for half an hour in the reaction kettle, then add water and solubilizing and dispersing agent in turn and stir until uniform .

Embodiment 3

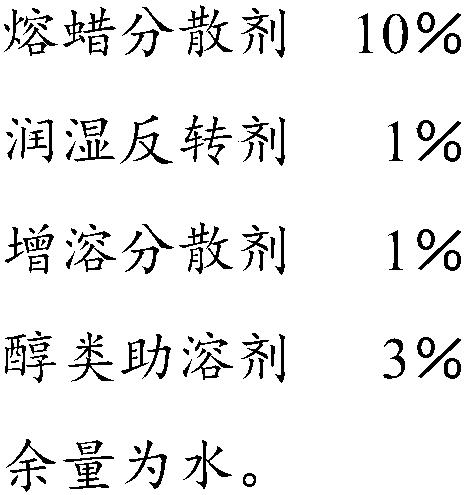

[0045] A water-based wax remover, comprising the following raw material components in percentage by weight:

[0046]

[0047] Among them, the melting wax dispersant is a 1:1 mixture of polyethylene glycol dioleate and fatty acid methyl ester ethoxylate sulfonate, the wetting reversal agent is polyoxyethylene alkylphenol ether, and the solubilizing and dispersing agent is Polyethylene glycol dioleate, fatty alcohol polyoxyethylene ether, nonylphenol polyoxyethylene ether 1:1:1 mixture, alcohol co-solvent is methanol, ethanol, n-butanol according to the ratio of 3:2:1 mixture.

[0048] The preparation method of the above water-based wax remover and anti-wax agent: add wax-melting dispersant, wetting reversal agent and solubilizing dispersant to the reaction kettle and mix evenly, then add alcohol co-solvent and stir for half an hour, add water and stir until uniform.

[0049] Raw material component content value screening experiment:

[0050] According to the data in Table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com