Continuous immobilized multiphase reactor

A multiphase reactor and reactor technology, applied in chemical/physical/physical chemical fixed reactors, chemical instruments and methods, chemical/physical/physical chemical processes, etc., can solve the long production time and the danger of sampling under pressure , high energy cost and other issues, to achieve the effect of safe production and increased productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

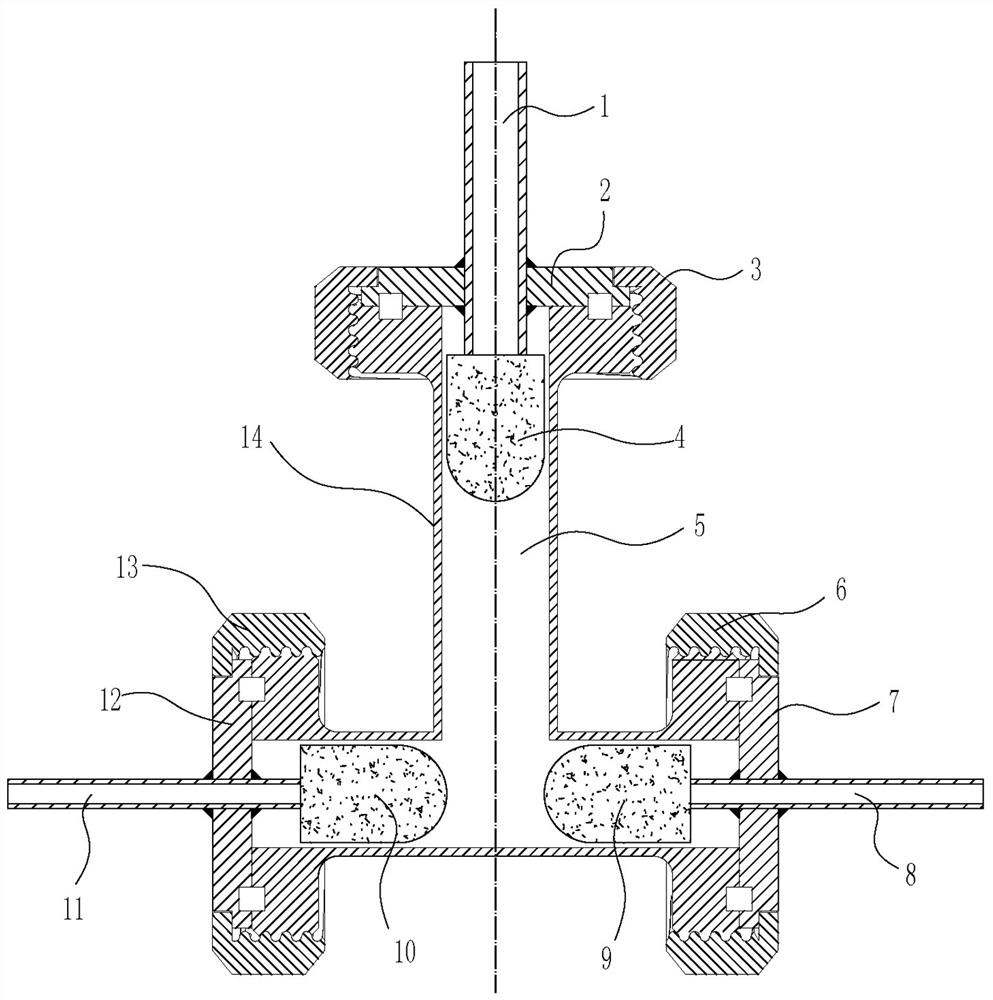

[0031] The reactor cylinder 14 of the present invention has a built-in reactor cavity 5, and the bottom and top of the reactor cylinder 14 are provided with an inlet and an outlet, and the reactor cylinder 14 has a connected lower chamber and an upper chamber. , the lower chamber is connected to the inlet, the lower chamber is divided into a left inlet and a right inlet, which can be used as the gas feed port 13 and the liquid feed port 6 respectively, and the upper chamber is connected with the discharge port 3. The connection mode of the inlet and outlet is detachable connection, which is convenient to connect with the inlet and outlet pipes of different sizes and models. The inlet and outlet pipes can be separated from the reactor cylinder 14 through the detachable connection, which can be quickly disassembled and installed, and has replaceability at the same time. It facilitates quick disassembly and replacement of the entire reactor cylinder 14, and also facilitates flushi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com