Bionic microcapsule containing molybdenum disulfide and preparing method and application of microcapsule

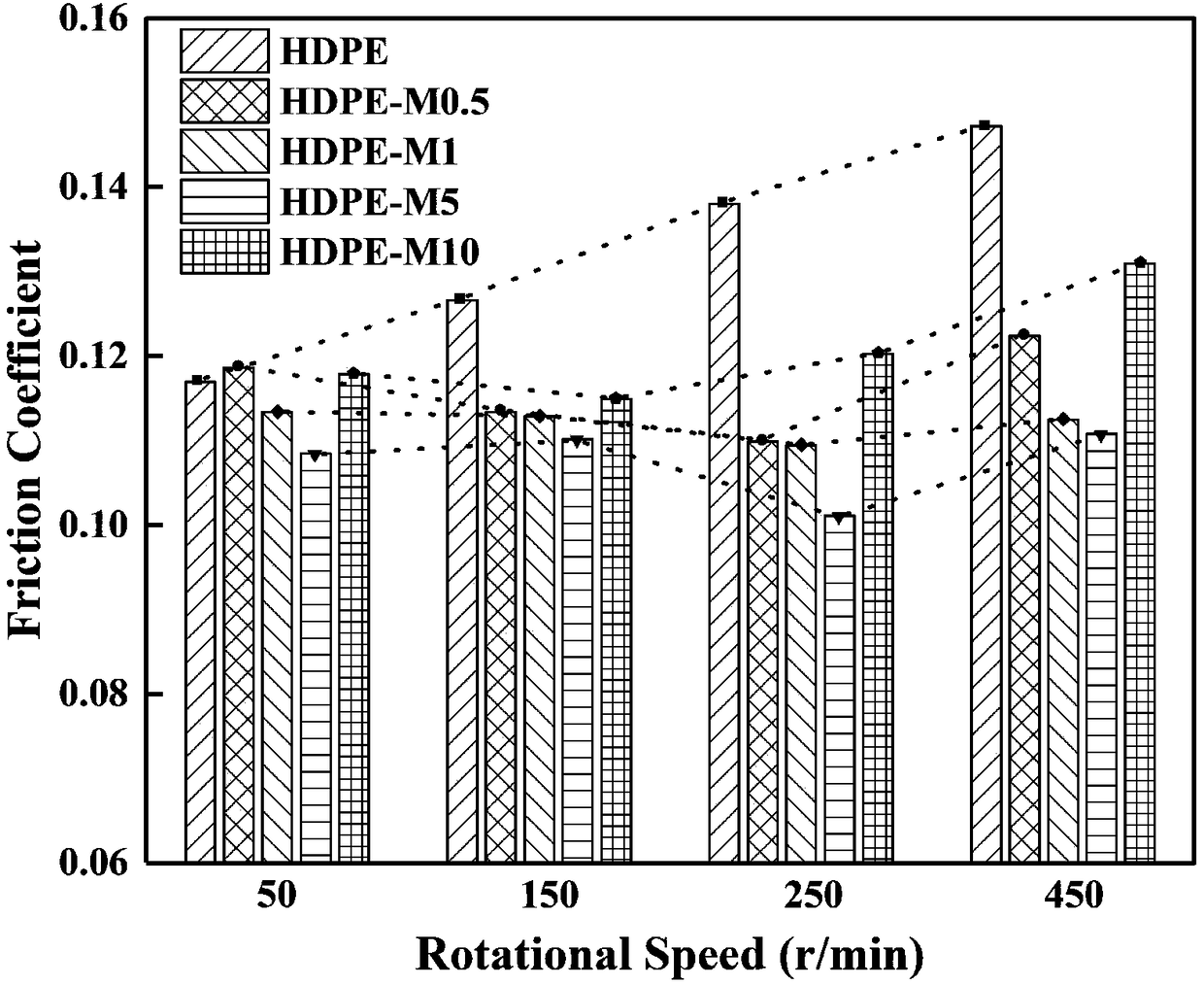

A technology of molybdenum disulfide and microcapsules, which is applied in the direction of microcapsule preparation and microsphere preparation, can solve the problems of low synthesis efficiency and general stability of microcapsule structure, and achieve the effect of reducing friction and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following examples further illustrate the technical solutions of the present invention, but are not intended to limit the protection scope of the present invention.

[0037] The preparation process of the biomimetic microcapsule containing molybdenum disulfide of the present invention is as follows:

[0038] 1) Preparation of wall material: Mix formaldehyde, urea and deionized water, the amount of formaldehyde and urea is 70%-80% formaldehyde and 20%-30% urea in terms of mass percentage, heat and stir to obtain urea-formaldehyde resin prepolymer , the reaction temperature is 70°C;

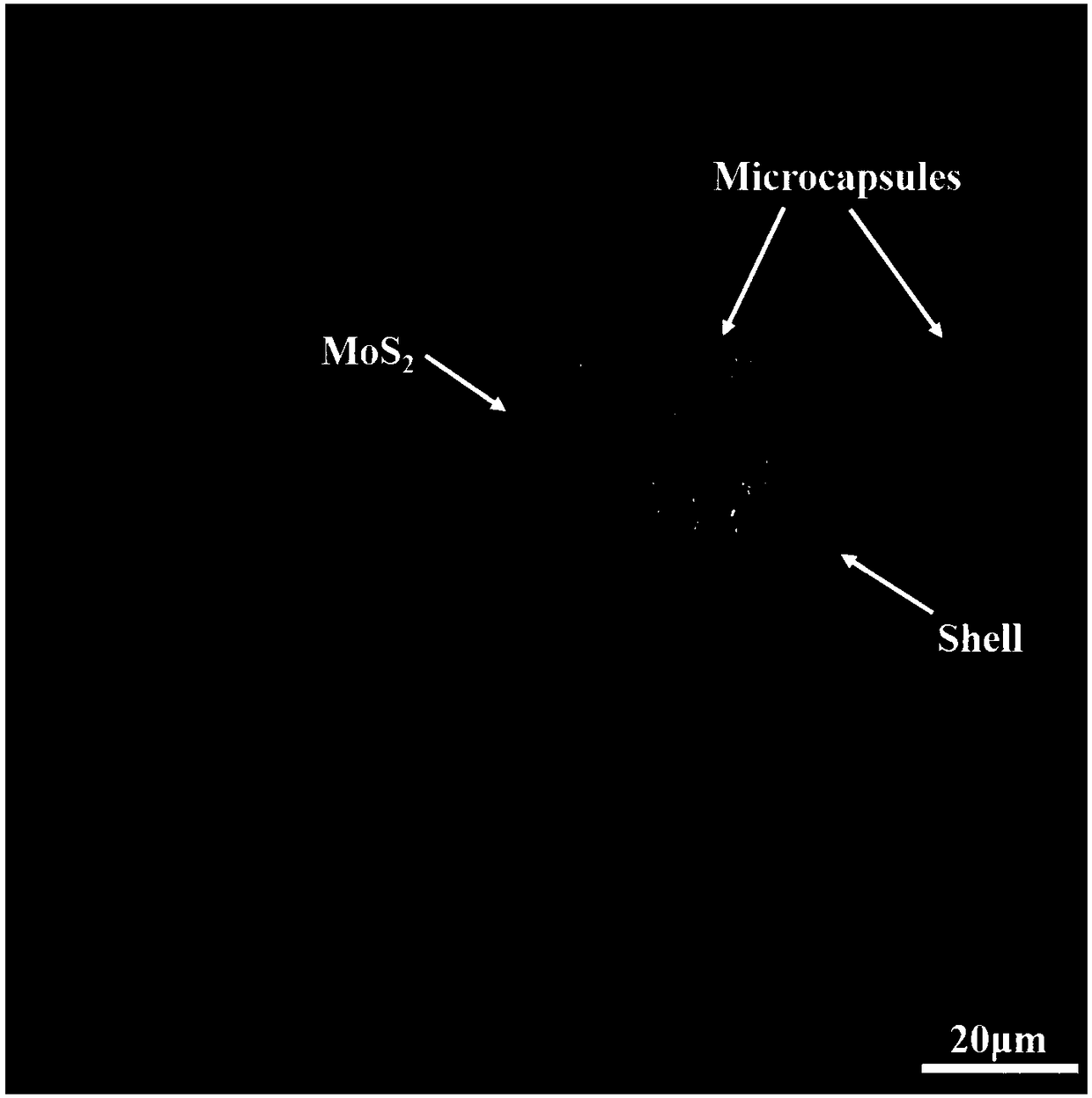

[0039] 2) Preparation of the core material suspension: adding molybdenum disulfide to a solution with an emulsifier (sodium lauryl sulfate) content of 2 wt%, and ultrasonically dispersing to obtain a molybdenum disulfide suspension;

[0040] 3) Using toluene as a solvent, the urea-formaldehyde resin prepolymer and molybdenum disulfide suspension are slowly added to the external water ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com