Method for fabricating MEMS friction sensor based on visual alignment

A production method and visual alignment technology, which are applied in the process of producing decorative surface effects, the manufacture of microstructure devices, and the measurement of the property force of piezoresistive materials, etc. problems such as low sensitivity, to achieve the effect of improving accuracy and improving assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

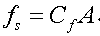

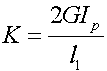

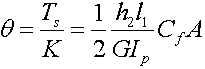

[0045] The structure of the MEMS friction sensor of the present embodiment is as figure 1 , figure 2 As shown, it is decomposed into package cover plate 1, floating element 2, silicon microstructure 3, electrode substrate 4, interface circuit 5 and package base 6, which are processed separately and then assembled. Package base 6 includes package positioning boss 8. Wherein, the floating element 2 includes a measuring head 9, a pole 10 and a positioning step 11, such as image 3 As shown; the silicon microstructure 3 includes a support frame 12, a torsion beam 13 and a vibrating plate 14, such as Figure 4 Shown; Electrode substrate 4 comprises lead electrode 15, glass boss 16 and gold electrode 17, as Figure 5 As shown; the vibrating plate 14 of the silicon microstructure 3 and the gold electrode 17 of the electrode substrate 4 form a differential sensitive capacitive element 18 to realize differential capacitance detection, as Image 6 As shown; the floating element 2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com