Processing method of non-circular raceway of aviation thin-walled bearing

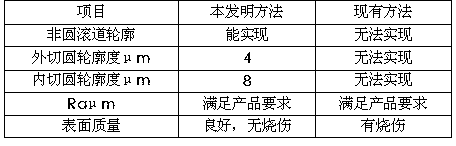

A technology of thin-walled bearings and processing methods, which is applied in the direction of metal processing equipment, manufacturing tools, grinding workpiece supports, etc., can solve the problems that cannot be realized, and achieve the effect of satisfying geometric shape accuracy and ensuring rotation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

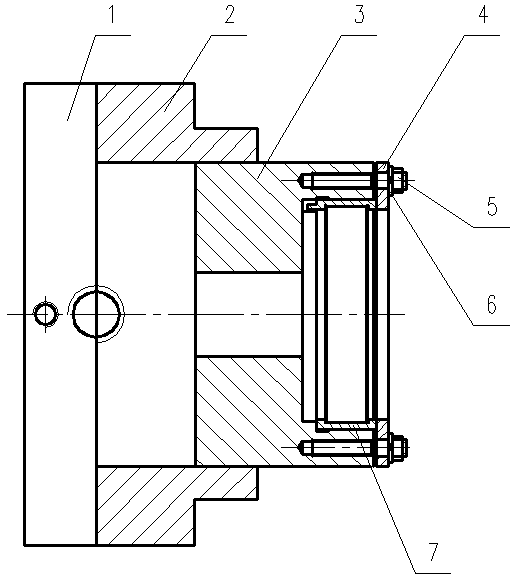

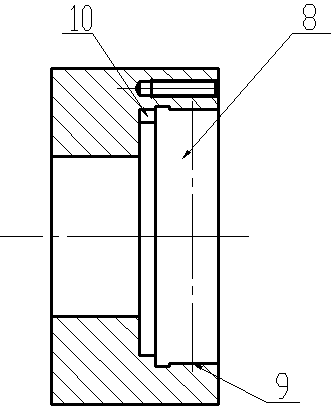

[0022] The invention is described in conjunction with accompanying drawings and specific embodiments:

[0023] A method for processing a non-circular raceway of an aviation thin-walled bearing, the specific steps of the processing method are as follows:

[0024] 1) Firstly, the inscribed circle radius r and circumscribed circle R are obtained according to the size of the non-circular raceway of the thin-walled bearing to be processed;

[0025] 2) According to the size of the non-circular raceway of the thin-walled bearing to be processed, a suitable workpiece, that is, the bearing ring, is selected as a raw material, and the inner diameter of the workpiece is smaller than the radius r of the inscribed circle of the non-circular raceway of the thin-walled bearing;

[0026] 3) Fix the workpiece on the machine tool through the auxiliary processing device;

[0027] 4) Select the high-speed grinding performance equipment. In this embodiment, the high-speed grinding performance equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com