Machining equipment and method for manufacturing various kinds of face gears through straight blade cutter

A technology for processing equipment and face gears, which is applied in the field of processing equipment for manufacturing various types of face gears with straight-edged tools, and can solve problems such as large tooth surface deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] The present invention is described in further detail below in conjunction with accompanying drawing:

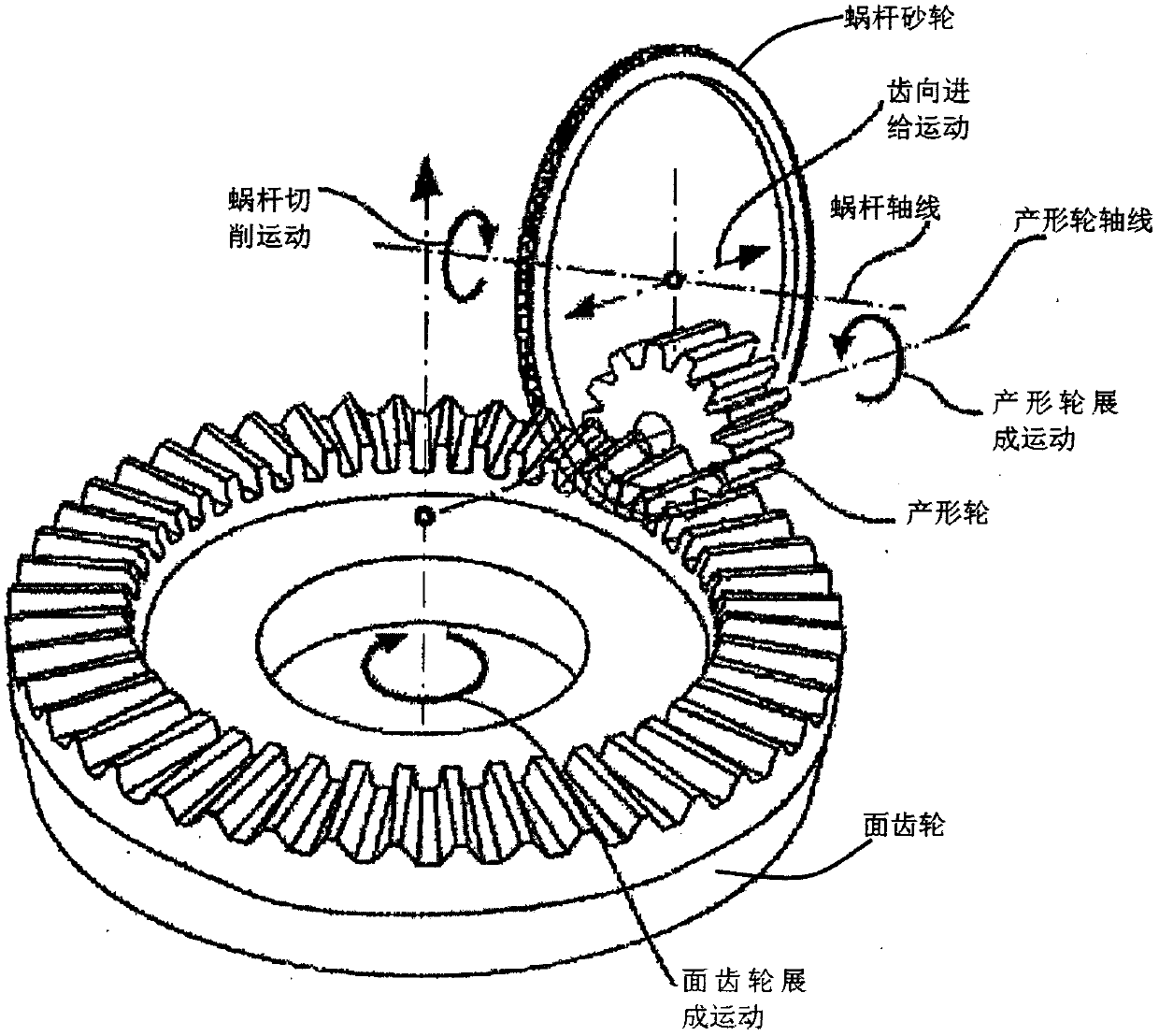

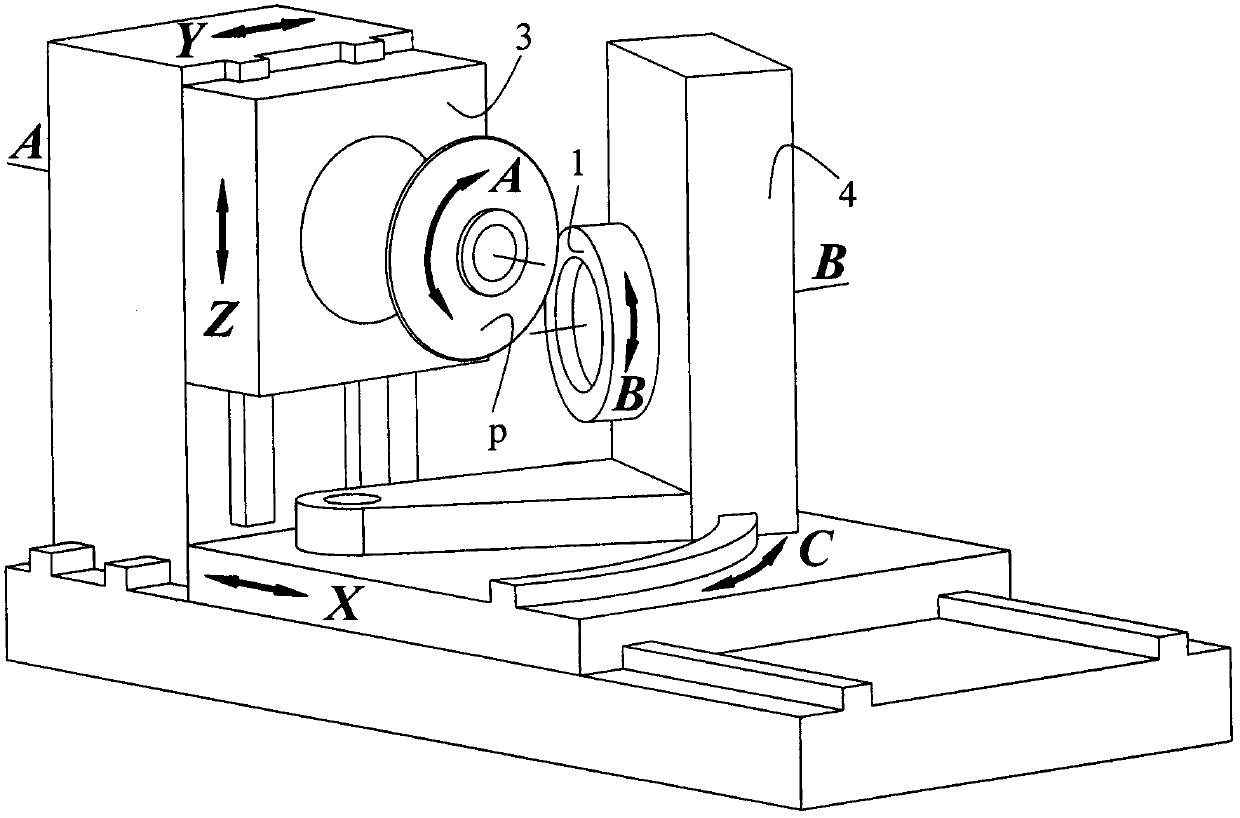

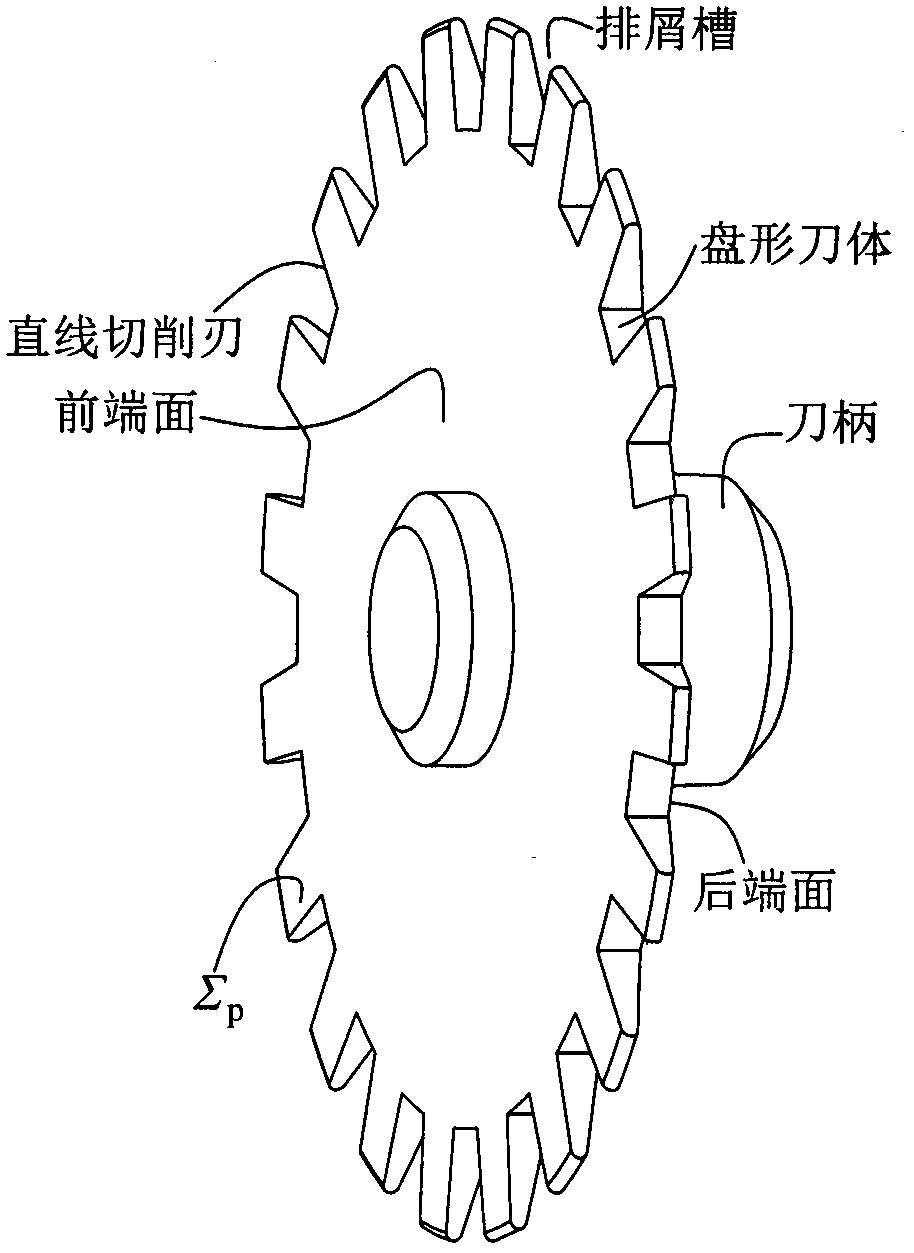

[0084]The technical problem solved by the present invention is: aiming at the problem that the current general tool can only cut the orthogonal spur tooth surface gear and introduce large tooth surface deviation on the existing machine tool, the processing equipment and the The processing method and the processing equipment include the used straight edge cutter, the existing bevel gear numerical control machine tool, the special fixture for the tool and the special fixture for the workpiece. And further expounds the processing method of using this equipment to manufacture various face gears, including the double-parameter and single-parameter envelope processing methods of various face gears. The double-parameter envelope processing can obtain various types of face gear tooth surfaces (theoretical tooth surface), but the efficiency is not high. It is suitable for high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com