Artificial intelligence corn quality detection robot and quality detection method

A technology of artificial intelligence and robotics, which is applied in the direction of sorting and optical testing for flaws/defects, etc., can solve problems such as endless output, visual information interference, and no unified measurement tool, to achieve continuous feeding, improve quality inspection efficiency, Solve the effect of detection index drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

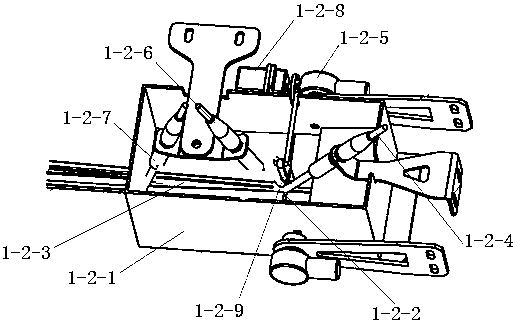

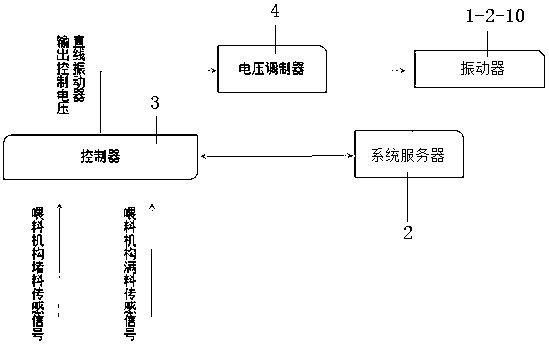

[0045] refer to Figure 1-Figure 4 , an artificial intelligence corn quality inspection robot, comprising an artificial intelligence corn quality inspection robot main body 1 and a system server 2; the artificial intelligence corn quality inspection robot main body 1 includes a box body, and the box body is provided with a material inlet 1- 1 and the discharge port, the box is equipped with a two-way feeding mechanism 1-2, a transmission mechanism 1-3, an upper and lower double-sided machine vision mechanism 1-4 and a two-way sorting mechanism 1-5, and the input The feed port 1-1 is connected with the two-way feeding mechanism 1-2, and the two-way feeding mechanism 1-2 is connected with the transmission mechanism 1-3 through the guide bar 1-6, and the transmission mechanism 1-3 Through the upper and lower double-sided machine vision mechanism 1-4, the transmission mechanism 1-3 is connected to the discharge port, and the two-way sorting mechanism 1-5 is located behind the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com