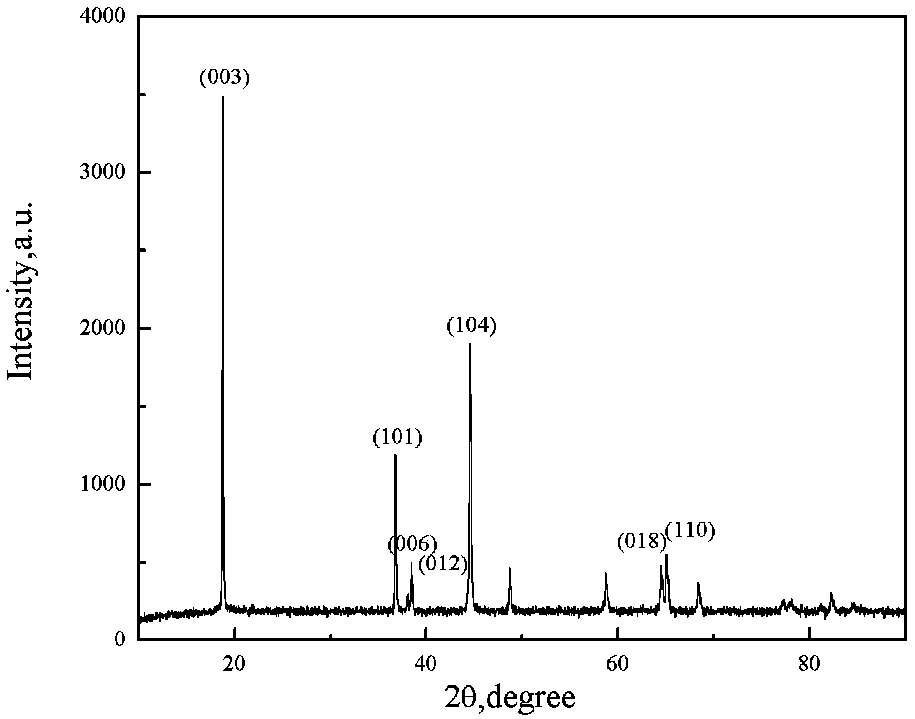

LiAlO2/C modified ternary composite material as well as preparation method and application thereof

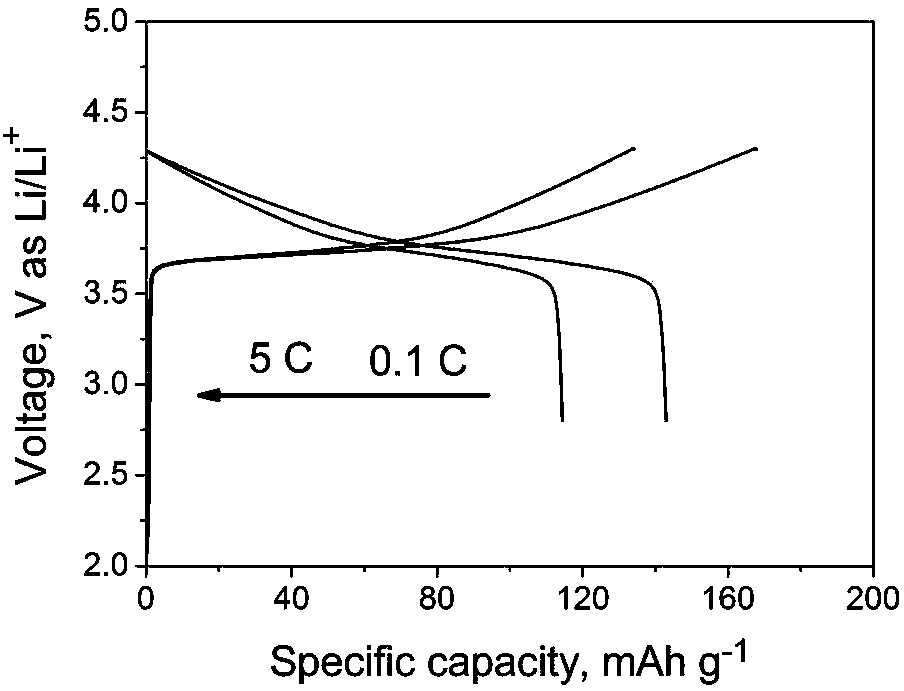

A technology of composite materials and powder materials, which is applied in the field of preparation of LiAlO2/C modified ternary composite materials, can solve the problems of poor high-rate performance, low tap density, capacity attenuation, etc., and achieve improved rate performance and Effects of cycle stability, erosion reduction, and protection of material structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a LiAlO 2 / C modifies the preparation method of ternary composite material, comprises the following steps:

[0029] Step 1: Mix lithium source solution, nickel salt solution, cobalt salt solution and manganese salt solution to obtain the first mixed solution; wherein, the concentrations of lithium source solution, nickel salt solution, cobalt salt solution and manganese salt solution are preferably 0.01~ 5mol / L, more preferably 0.01mol / L, 1mol / L, 2.5mol / L, 4mol / L or 5mol / L; among them, the lithium source is preferably lithium dihydrogen phosphate, lithium acetate, lithium fluoride, perchloric acid One or more of lithium, lithium hexafluorophosphate, lithium carbonate and lithium hydroxide, more preferably lithium hydroxide, lithium acetate or lithium carbonate; the nickel salt is preferably nickel nitrate, nickel sulfate and or nickel acetate; the cobalt salt is preferably nitric acid Cobalt, cobalt sulfate or cobalt acetate; the manganese salt i...

Embodiment 1

[0049] 1. Dissolve lithium hydroxide, nickel sulfate, cobalt sulfate and manganese sulfate in deionized water respectively to prepare four aqueous solutions with a concentration of 0.01mol / L, and mix the four solutions, wherein the hydroxide of these four solutions The molar ratio of lithium, nickel sulfate, cobalt sulfate and manganese sulfate is 3:1:1:1.

[0050] 2. Add citric acid to the above mixed solution according to the molar ratio of metal ions and citric acid in the above mixed solution is 1:1.

[0051] 3. Stir the mixed solution obtained above at 100°C for 10 hours, evaporate all the deionized water to obtain a gel substance, and then vacuum-dry it in a vacuum oven at a temperature of 100°C for 12 hours, then take out the dry matter and perform ball milling.

[0052] 4. Finally, the crushed powder material was sintered in the air atmosphere from 25°C to 500°C at 1°C / min for 5 hours, then raised to 750°C in the air atmosphere at 1°C / min and kept for 8 hours, and natu...

Embodiment 2

[0061] 1. Dissolve lithium acetate, nickel nitrate, cobalt nitrate and manganese nitrate in deionized water respectively to prepare four aqueous solutions with a concentration of 1mol / L, and mix the four solutions, wherein the lithium acetate and nitric acid of these four solutions The molar ratio of nickel, cobalt nitrate and manganese nitrate is 3:1:1:1.

[0062] 2. Add glycine to the above mixed solution according to the molar ratio of metal ions and glycine in the above mixed solution is 1:2.

[0063] 3. The mixed solution obtained above was stirred at 120° C. for 12 hours, and all the deionized water was evaporated to dryness to obtain a gel substance, which was then vacuum-dried in a vacuum drying oven at a temperature of 120° C. for 13 hours, and then the dried product was taken out and crushed by ball milling.

[0064] 4. Finally, the crushed powder material was sintered in the air atmosphere from 25°C to 530°C at 2°C / min for 6 hours, then raised to 800°C at 2°C / min in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com