Catalyst for reaction for preparing 1,3-butadiene from ethanol, preparation and applications thereof

A catalyst and butadiene technology, applied in the direction of catalysts, molecular sieve catalysts, carbon compound catalysts, etc., can solve the problem of less impact, and achieve the effects of favorable utilization, excellent reaction performance, and inhibition of side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] One, the preparation of 1Na-3Zn-10Hf-MFI catalyst

[0028] (1) In the mixed solution of ethyl orthosilicate and water, add 25wt% tetrabutylammonium hydroxide aqueous solution dropwise, stir for 12h to obtain a molar composition of 1.0 ethyl orthosilicate: 3.0 tetrabutylammonium hydroxide: 10-100 water the gel;

[0029] (2) Put the obtained gel into a stainless steel hydrothermal kettle and crystallize at 100°C for 6 days;

[0030](3) The obtained white powder was centrifuged, dried at 80° C. for 12 hours, and calcined at 600° C. for 5 hours to obtain an MFI molecular sieve with a nanosheet structure.

[0031] (4) Na 2 CO 3 , Zn(NO 3 ) 2 6H 2 O and HfCl 4 Dissolved in water, impregnated with the above-mentioned nanosheet MFI molecular sieve in equal volume, and dried in an oven at 80°C.

[0032] (5) Calcining the sample in step 4 at 550° C. for 4 hours to obtain the nanosheet molecular sieve catalyst 1Na-3Zn-10Hf-MFI.

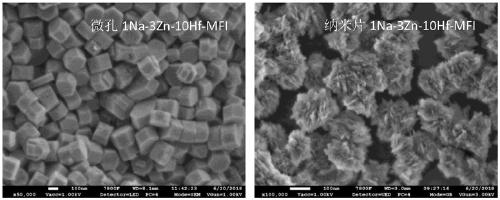

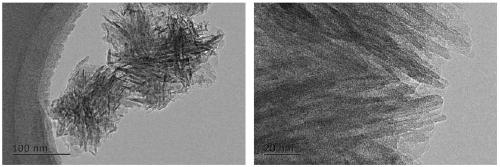

[0033] The scanning electron microscope a...

Embodiment 2

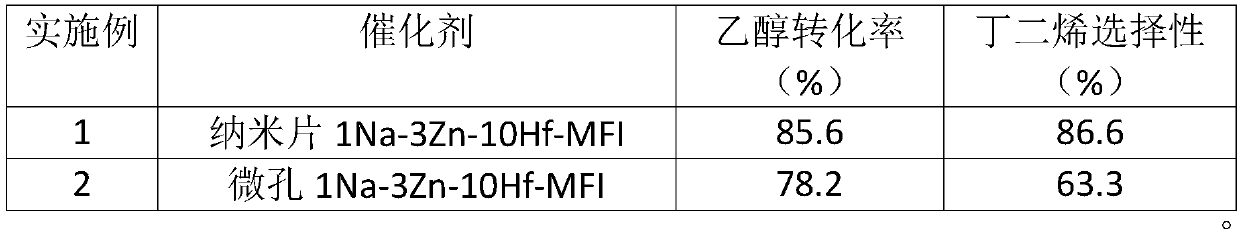

[0041] The difference between Example 2 and Example 1 is that the prepared catalyst is a microporous molecular sieve catalyst 1Na-3Zn-10Hf-MFI, and other reaction conditions are the same as in Example 1. The specific experimental results are shown in Table 1.

[0042] The preparation method of microporous molecular sieve catalyst 1Na-3Zn-10Hf-MFI is as follows: HfCl 4 Dissolve in water, under stirring condition, add ethyl orthosilicate dropwise to the above solution, stir for 3h, then add 25wt% tetrapropylammonium hydroxide aqueous solution dropwise, stir for 12h; put the obtained gel into In a stainless steel hydrothermal kettle, crystallize at 160°C for 3 days; centrifuge the obtained white powder, dry, and roast at 600°C for 4 hours to obtain an MFI molecular sieve containing Hf; 2 CO 3 , Zn(NO 3 ) 2 6H 2 O was dissolved in water, impregnated with the above Hf-containing MFI molecular sieve in equal volume, dried, and calcined at 550° C. for 4 hours to obtain the micr...

Embodiment 3

[0047] The difference between Example 3 and Example 1 is that the prepared catalyst is nanosheet molecular sieve catalyst 1Li-3Zn-10Y-MFI, and other reaction conditions are the same as Example 1. The specific experimental results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com