Fault diagnosis device for numerically-controlled machine tool

A fault diagnosis device, the technology of numerical control machine tools, applied in the direction of program control, computer control, general control system, etc., can solve the problems of maintenance personnel difficulty, high price, difficult maintenance, etc., to save maintenance time, easy to use, and easy to use. The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

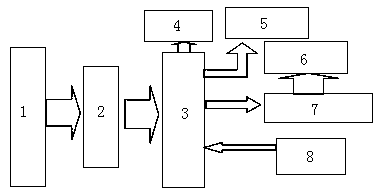

[0013] Such as figure 1 Shown: a CNC machine tool fault diagnosis device, which includes a sensor, a signal pick-up circuit, a processing unit, an alarm, an LED indicator light, an LCD display, a drive circuit and a button 8 for setting working parameters;

[0014] The sensor is installed on the CNC machine tool 1, and the signal pickup circuit 2 processes the signal detected by the sensor to form a standard signal input processing unit. The processing unit 3 compares the input signal with the characteristic value, and the value exceeding the set value will pass through the alarm 4 and the LED indicator light 5 send an alarm message, and the information is displayed on the LCD display 6 through the drive circuit 7 at the same time; the processing unit is a STC single-chip microcomputer.

[0015] The fault diagnosis device is connected with the CNC machine tool. Some signal collection points are set on the CNC machine tool. The information of these collection points is input in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com