Testing device for fracturing fluid distribution for multi-perforation cluster near wellbore resistance factor

A technology for testing devices and perforation clusters, applied in wellbore/well components, production fluids, earthwork drilling and production, etc., can solve the differences in the size of main fractures and effective conductivity, weaken the coverage and complexity of fracture networks, and influence Shale reservoir stimulation effect and other issues, to achieve the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of one or more embodiments. It may be evident, however, that these embodiments may be practiced without these specific details. In other instances, well-known structures and devices are shown in block diagram form in order to facilitate describing one or more embodiments.

[0014] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

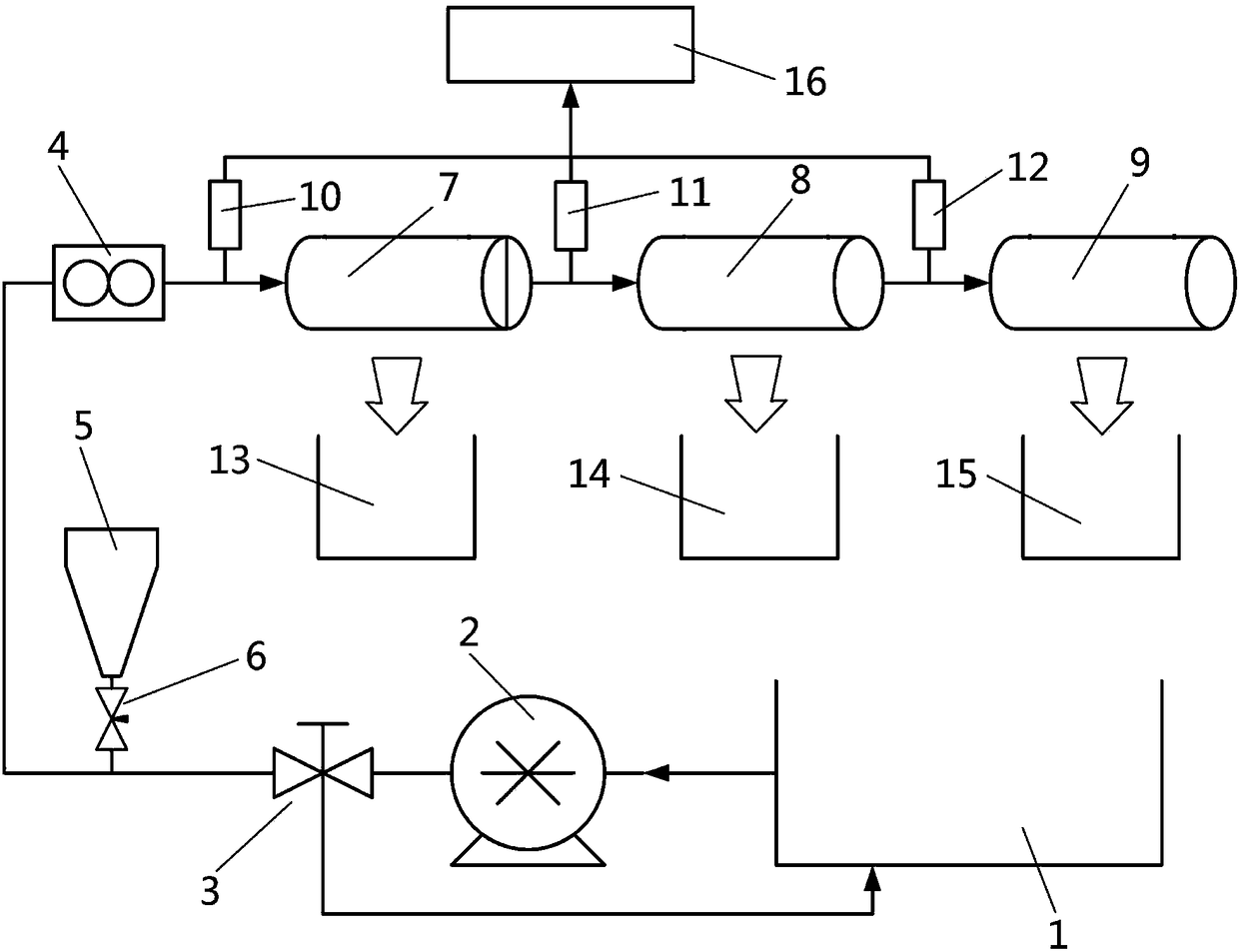

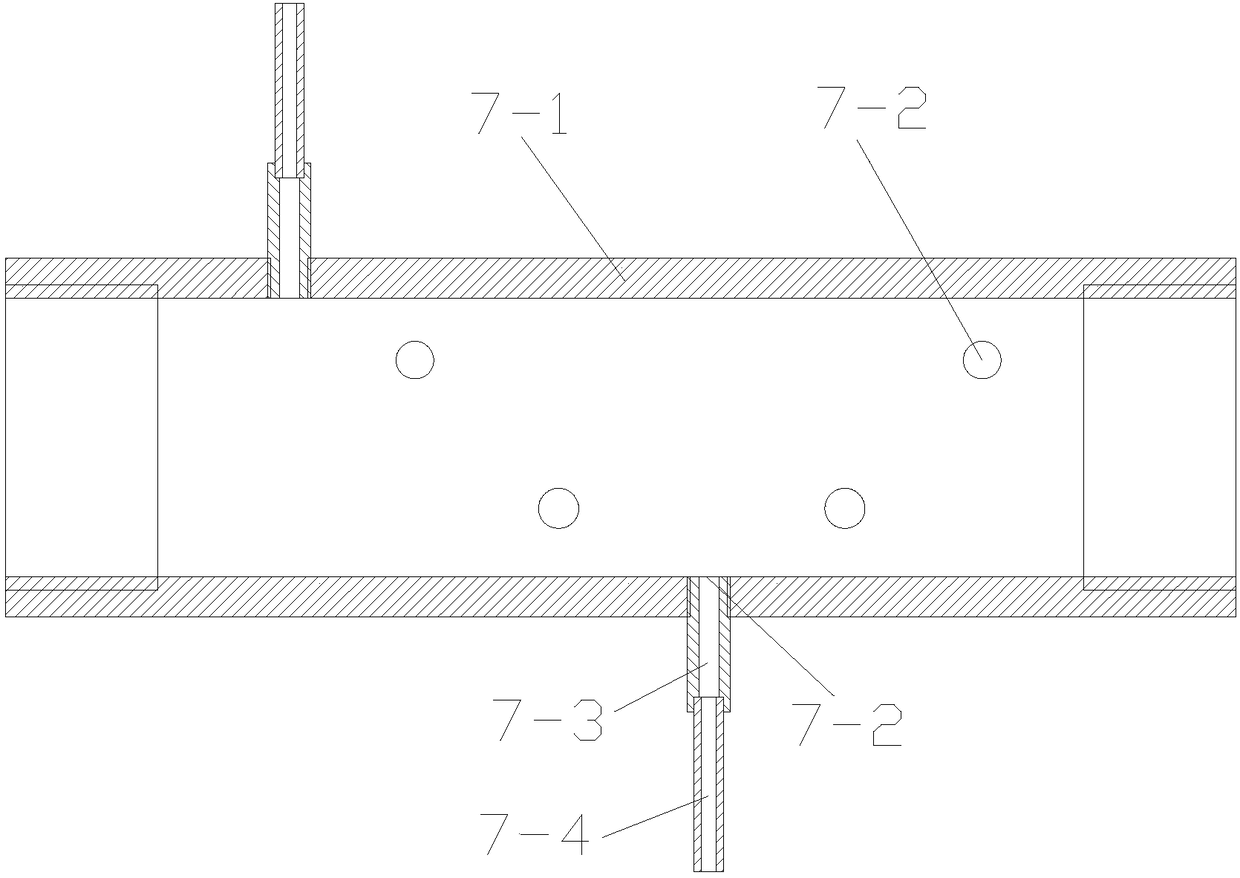

[0015] The present invention aims to build a test device that is consistent with the actual situation on the spot and reflects as much as possible the difference between casing, perforation, and fracture bending near the wellbore on the fluid flow in the wellbore. The distribution law of sand-carrying fluid among the perforation clusters under the conditions of flow mode and flow velocity.

[0016] figure 1 The structure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com