Truss bridge system for truss-rope composite structure

A composite structure and truss bridge technology, applied in the field of truss bridge system, can solve the problems of prolonged construction period, insufficient torsional rigidity, and ignoring the influence of load factors such as eccentric force, and achieve the reduction of vertical deflection and lateral deflection , The torsion resistance of the bridge body is improved, and the effect of improving the comfort of pedestrians

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below with reference to the accompanying drawings and specific implementation methods, and the embodiments will not be repeated here one by one, but the applicability of the present invention is not limited to the following embodiments.

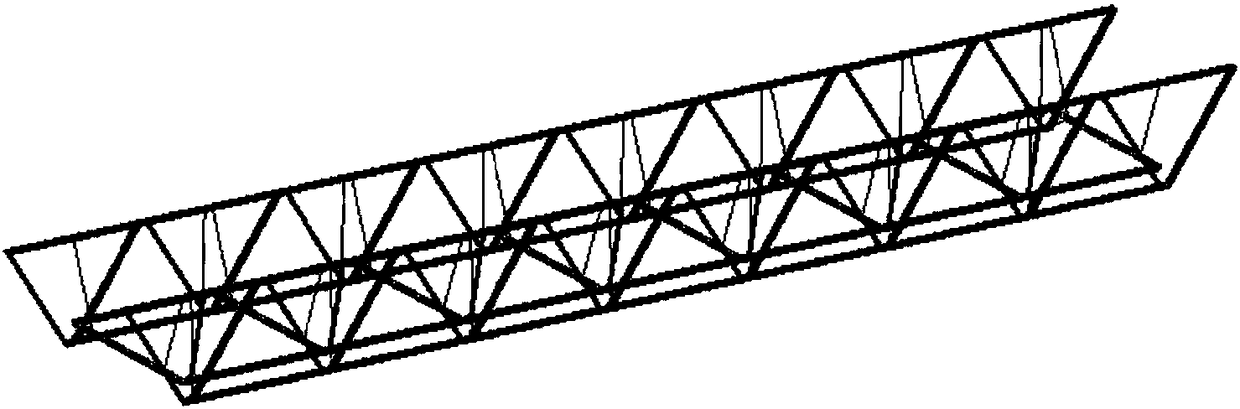

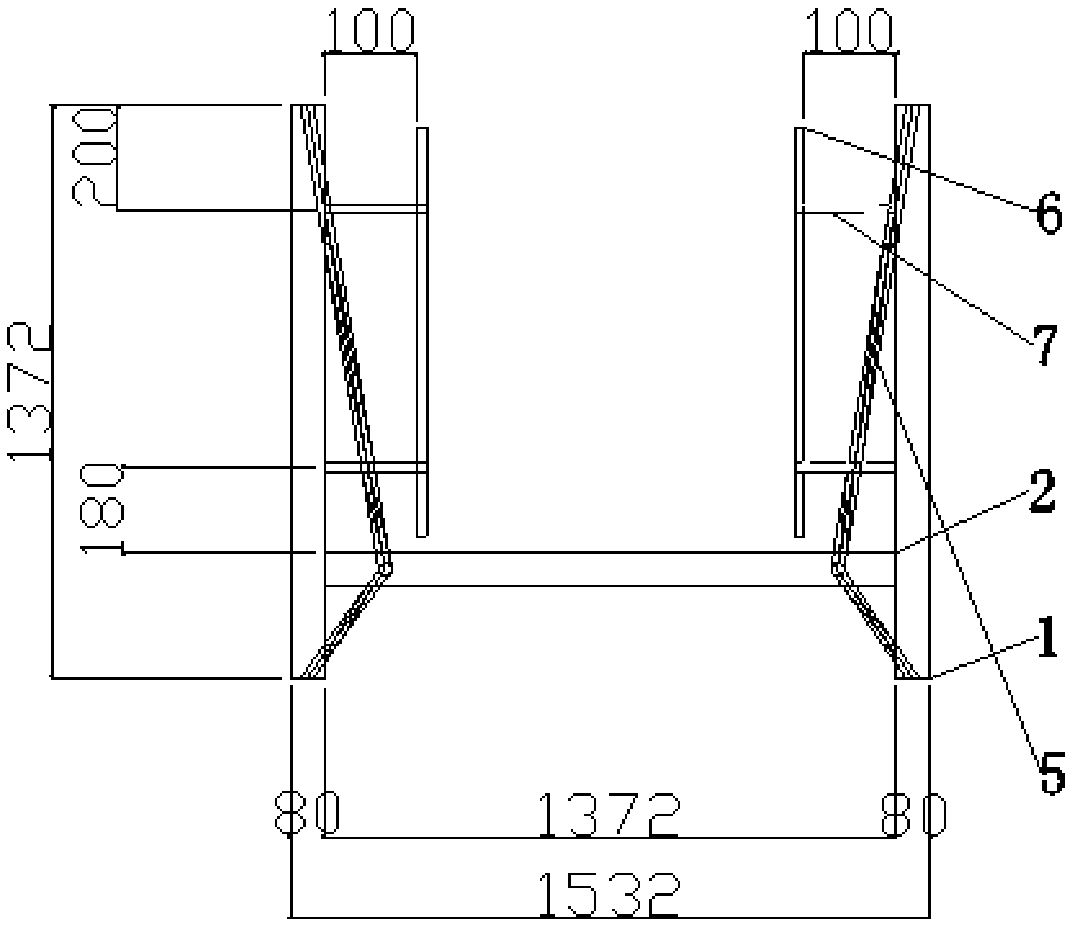

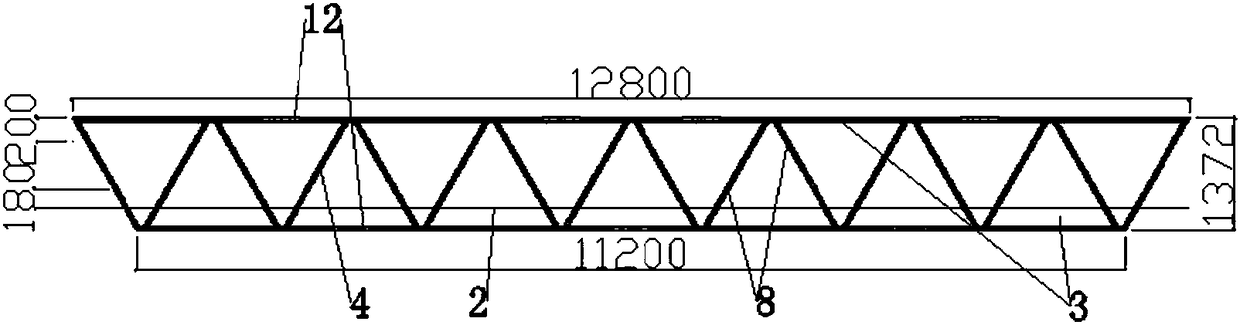

[0041] Such as figure 1 , figure 2 As shown, a truss bridge system of a truss-cable composite structure, including a light steel bridge skeleton, supports the support arranged at the bottom of the light steel bridge skeleton through several bottom connectors 15, and the light steel bridge skeleton includes Q235 A light steel handrail truss 1 and a light steel walkway truss 2 assembled with cold-formed thin-walled steel. The light steel handrail truss 1 is symmetrically fixed on both sides of the light steel walkway truss 2 . 1. A number of steel cables 5 are evenly spaced along the length direction between the lower chords. The reserved holes corresponding to the web members 4 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com