High-hydroscopicity non-woven fabric edge cutter

A super absorbent, non-woven technology, applied in the field of machinery, can solve the problems of uneven width, non-uniform width of non-woven fabrics, inability to ensure the uniformity of the elastic state of super absorbent non-woven fabrics, etc. Compact, even width effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

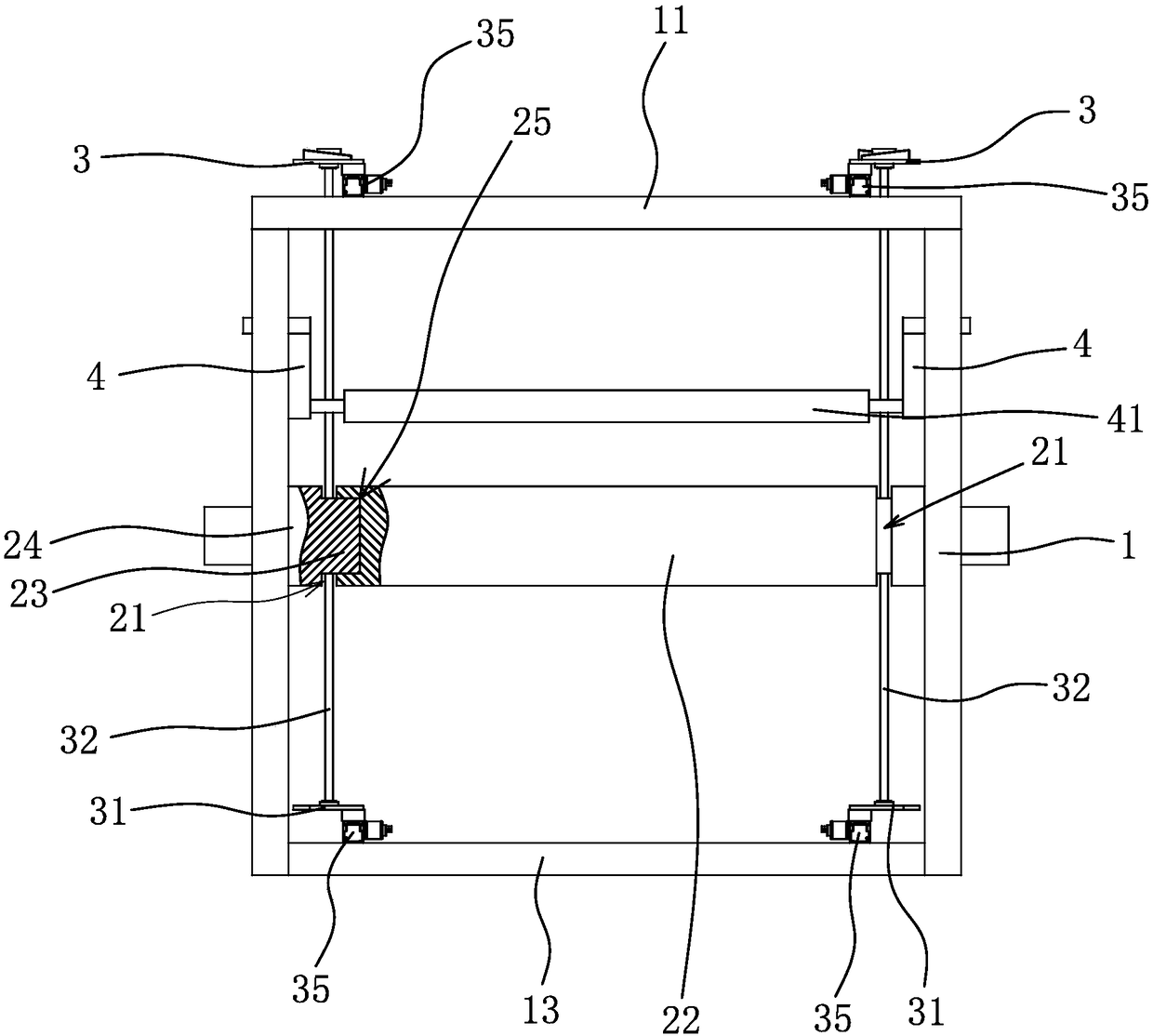

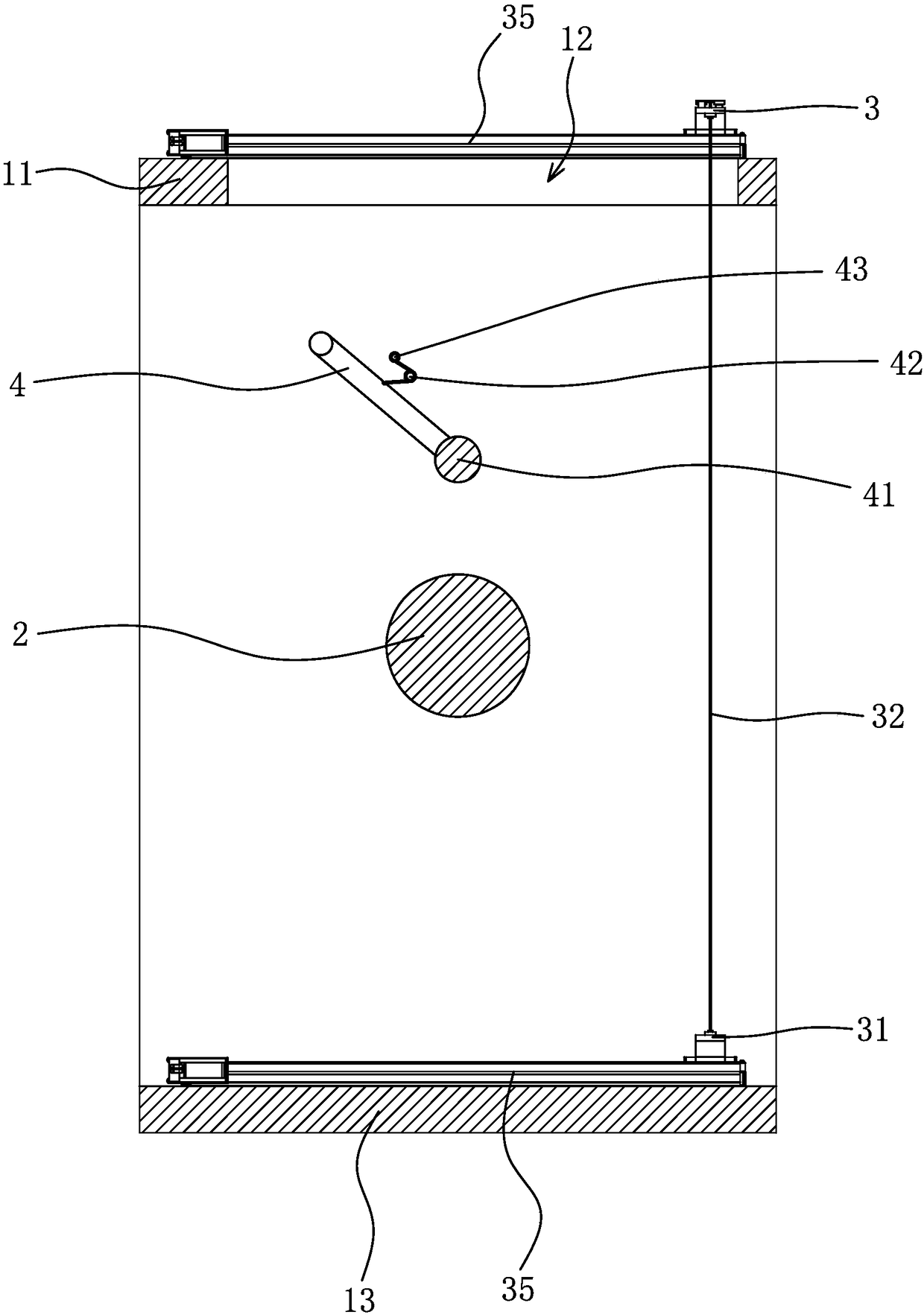

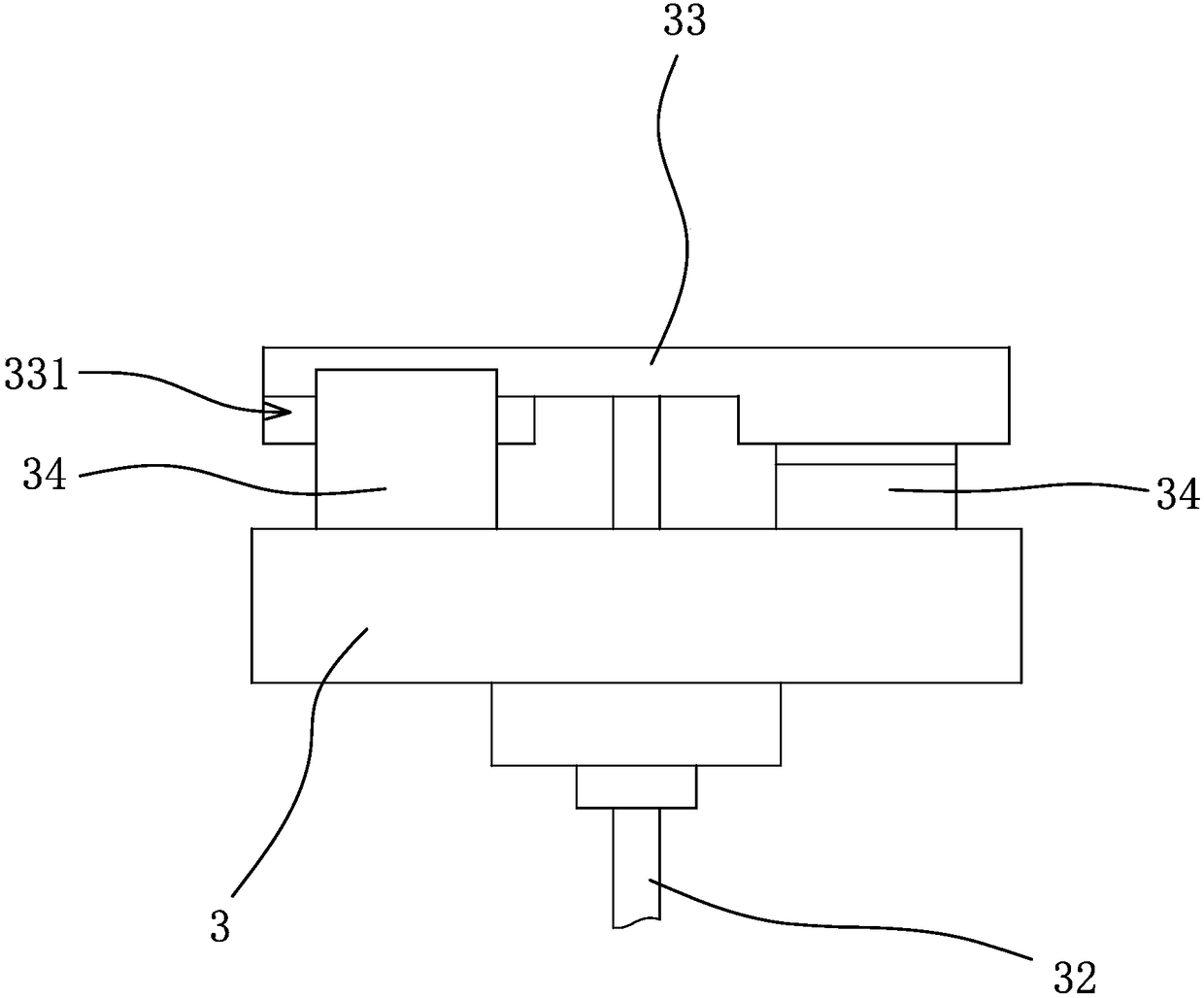

[0018] Such as Figure 1 to Figure 3 As shown, the edge trimming machine for highly water-absorbent non-woven fabrics includes a frame 1 on which a cloth receiving roller 2 is rotatably connected, and the cloth receiving roller 2 is provided with trimming grooves 21 near both ends. The frame 1 is provided with two sets of cutting assemblies corresponding to the trimming grooves 21 one by one, and each set of cutting assemblies includes an upper slide seat 3, a lower slide seat 31 and a cutting line connected between the upper slide seat 3 and the lower slide seat 31 32, the cutting line 32 is a steel wire, the upper sliding seat 3 is slidably connected to the top plate 11 of the frame 1, the lower seat 31 is slidably conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com