Metal tungsten surface nanocrystallization device and method thereof

A technology of metal tungsten and nanotechnology, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of high processing cost, complicated operation process, complex structure of metal tungsten surface nanotechnology devices, etc. , to achieve the effect of simple preparation process, easy operation process and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

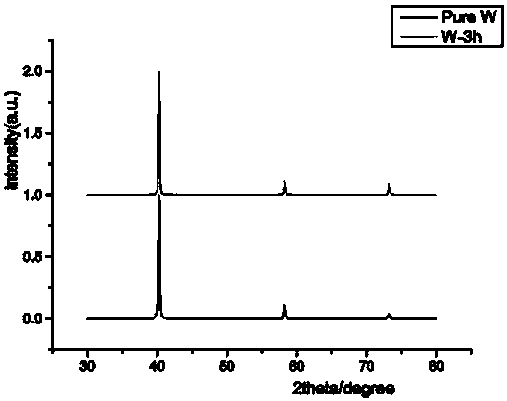

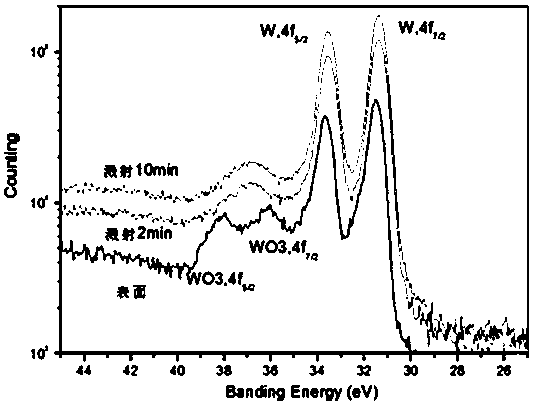

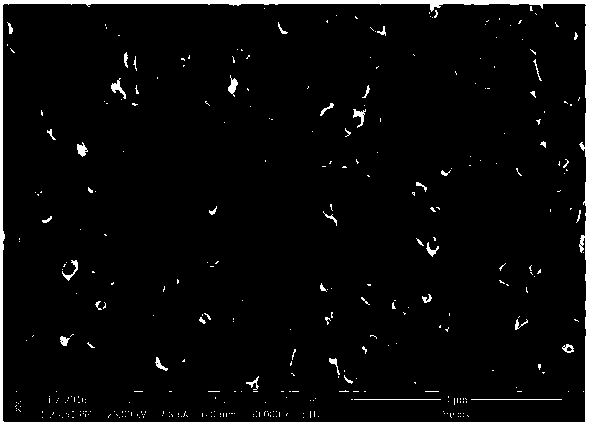

Embodiment 1

[0039] The specific implementation steps of the nanometerization of the surface of the metal tungsten sheet 8 are as follows:

[0040] (1) Pre-treatment of the nano-sized metal tungsten sheet 8: the metal tungsten sheet 8 is sequentially polished with 500-mesh, 800-mesh, and 1200-mesh sandpaper to remove the surface oxide layer and mechanical processing marks, and then polished to the mirror surface with 1 μm abrasive paste, and then Using ethanol, acetone and compressed nitrogen in sequence to clean the surface of the metal tungsten sheet 8;

[0041] (2) Vacuum environment: place the metal tungsten sheet 8 on the tungsten cylinder 6, and evacuate the vacuum chamber 1 to a vacuum degree of 3×10 - 4 Pa;

[0042] (3) Argon gas cleaning: In the vacuum chamber 1, argon gas is introduced to 80Pa, and a bias voltage is applied to ionize the argon gas to form an energy of 1000eV on the surface of the metal tungsten sheet 8, and a beam intensity of 150 μA / cm 2 The argon ion beam is...

Embodiment 2

[0046] The specific implementation steps of the nanometerization of the surface of the metal tungsten sheet 8 are as follows:

[0047] (1) Pre-treatment of the nano-sized metal tungsten sheet 8: the metal tungsten sheet 8 is sequentially polished with 500-mesh, 800-mesh, and 1200-mesh sandpaper to remove the surface oxide layer and mechanical processing traces, and then polished to a mirror surface with 3 μm abrasive paste, and then Using ethanol, acetone and compressed nitrogen in sequence to clean the surface of the metal tungsten sheet 8;

[0048] (2) Vacuum environment: place the metal tungsten sheet 8 on the tungsten cylinder 6, and evacuate the vacuum chamber 1 to a vacuum degree of 3×10 - 4 Pa;

[0049] (3) Argon gas cleaning: In the vacuum chamber 1, argon gas is introduced to 30Pa, and biased ionized argon gas is applied to form an energy of 500eV on the surface of the metal tungsten sheet 8, and a beam intensity of 50 μA / cm 2 The argon ion beam is used to perform ...

Embodiment 3

[0053] Preferably, the specific implementation steps of the nanometerization of the surface of the metal tungsten sheet 8 are as follows:

[0054] (1) Pre-treatment of the nano-sized metal tungsten sheet 8: the metal tungsten sheet 8 is sequentially polished with 500-mesh, 800-mesh, and 1200-mesh sandpaper to remove the surface oxide layer and mechanical processing marks, and then polished to a mirror surface with 2 μm abrasive paste, and then Using ethanol, acetone and compressed nitrogen in sequence to clean the surface of the metal tungsten sheet 8;

[0055] (2) Vacuum environment: place the metal tungsten sheet 8 on the tungsten cylinder 6, and evacuate the vacuum chamber 1 to a vacuum degree of 3×10 - 4 Pa;

[0056] (3) Argon gas cleaning: In the vacuum chamber 1, argon gas is introduced to 70Pa, and biased ionized argon gas is applied to form an energy of 800eV on the surface of the metal tungsten sheet 8, and a beam intensity of 100 μA / cm 2 The argon ion beam is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com